|

| From an article in the 1892-09-20 Iron Age |

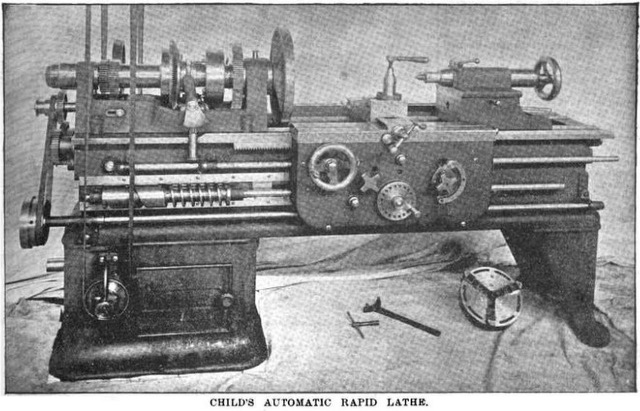

The Automatic Rapid Lathe Co. was founded in 1892 by Eugene Childs to make the Childs’ Automatic Rapid Lathe. The key feature of this lathe was that the spindle speed automatically increased as the tool moved closer to the centre axis of the work. By 1895 the lathe was being built and sold by the Blanchard Machine Co., by 1898 Childs was superintendent of wrench maker Trimont Manufacturing Co., and by 1899 the Automatic Rapid Lathe Co. was formally dissolved.

Automatic Rapid Lathe Co. was founded with a capital stock of $250,000, which at the time was more than adequate for starting a machine tool manufacturing business. A search has turned up only one article on their lathe, and no advertisements at all. Sadly, Blanchard Machine had little experience in making and selling lathes and the Childs lathe did not achieve success with Blanchard either.

Information Sources

- American Lathe Builders: 1810-1910 by Kenneth L. Cope, 2001 page 7.

- 1892-07-14 Iron Age.

The Automatic Rapid Lathe Company have been organized at Saco, Maine, with a capital stock of $250,000 for the purpose of manufacturing and dealing in machinery.

- December 1895 Machinery, in a report on The Mechanics' Fair, which was then underway in Boston.

Across the aisle from this is rather a novel lathe, called the Childs' Automatic Rapid Lathe, built by the Blanchard Machine Company, 303 Congress street, Boston, Mass. It is a very heavy lathe of 16-inch swing, having two driving belts, each 2 inches wide, running 1,350 feet per minute, transmitting about 6 HP. Spindle bearings are 3 7/8 X 4 1/4 inches and 2 7/8 X 4 inches long respectively, and the spindle has a 1 3/4 inch hole through it. The weight of the lathe is 2,700 pounds, which gives an idea of its proportions. When the tool is moved to or from the center, the speed of the work varies so as to keep a constant speed at the tool, which is quite a time saver on work of varying diameters. This relation of speed to position of tool is automatically maintained with both hand and power cross feed. The limit of variation is from 8 to 175 revolutions, a range sufficient for ordinary work. The speed is easily varied by a small index lever, and the operator can stand in his usual position and watch the tool, increasing the speed as much as the tool will stand, and this speed will be maintained regardless of the diameter of the work. The feeds can be instantly and accurately changed from 1/48 inch to 3/16 inch per revolution by an index. The lead screw is placed inside the bed, out of the way of dirt and in a position to avoid the twisting pull which so often occurs. The lathe can be set either parallel or at right angles to the counter, which is a very desirable feature in many cases.

- An article in the 1898-04-29 American Manufacturer and Iron World shows Childs' Turret Lathe. "This lathe is the invention of Eugene Childs, superintendent Trimont Manufacturing Company, Roxbury, Mass." Trimont made pipe and chain wrenches.

- The 1899 Public Documents of Maine has a list of "excused corporations", which includes Automatic Rapid Lathe Company.