Manufacturers Index - James Hamilton

James Hamilton

New York, NY, U.S.A.

Manufacturer Class:

Wood Working Machinery

Last Modified: Jun 20 2025 12:34PM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

James Hamilton was an important early innovator of sawing machinery, particularly for the ship-building industry. Considering the era in which he operated—spanning at least 1833 to 1864—we have been able to find a fair amount of information about his machines. Information on Mr. Hamilton himself is almost non-existent.

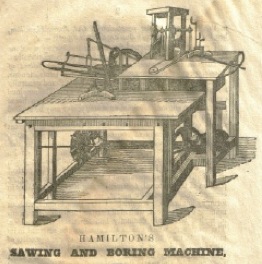

Image of the Hamilton felly machine, from an 1834 R. Hoe & Co. catalog.

In 1833, Hamilton was granted a patent for his machine for making fellies (wheel-rim segments). He managed to generate considerable publicity for his invention. A least some of Hamilton's wheel machines were manufactured and distributed by R. Hoe & Co., a firm that went on to become an important maker of printing presses.

During this early era of the Industrial Revolution, patents for machines were typically licensed to individual users who would then contract with a local machinist to make one for them. This model would become obsolete once manufacturing methodologies advanced to the point that manufactured machines were significantly less expensive than custom machines; at that point, it made more sense to license the invention to a manufacturer who would then sell machines that each came with an implicit license to use it. Hamilton's arrangement with R. Hoe & Co. represented a sort of hybrid between the two systems, where users were still expected to sign a licensing agreement with the inventor but they then could buy the machine from a manufacturer. So far as we know, R. Hoe & Co. did not have an exclusive right to manufacture the Hamilton wheel machine.

In 1836 Hamilton was granted a patent for a veneer cutting machine. In 1840 he was granted two patents: one for a pit-sawing machine and one for boat-mounted sawing machine for cutting snags and pilings. In 1842 he patented a reciprocating sawmill for curvilinear sawing, as for ship timbers. This was apparently a successful idea, as the following year he patented a much refined and improved version of his saw, which received wide notice in both America and Great Britain. He was also granted a British patent, and subsequently created a stir by filing a patent infringement lawsuit in London against fellow New Yorker John Cochran, who was eventually found to have infringed on Hamilton's patents.

Hamilton continued to patent improvements to his curvilinear sawing machine and continued to sell it into the 1860s. By the mid-1860s, Hamilton's machines were being surpassed by the ingenious saws of John Knowlton of Philadelphia.

Information Sources

- From the June 1833 issue of Mechanics' Magazine and Register of Inventions and Improvement (and this remains one of the earliest citation in all the thousands of American and Canadian makers listed here):

Hamilton's Patent Sawing And Boring Machine.—We have experienced much gratification in examining this useful laborsaving machine; and we are perfectly satisfied that it is destined to be of great public utility in cheapening the price of those articles which are in use by all classes of society, and will at the same time be a source of great profit to the ingenious mechanic who has invented it. We have no means of ascertaining the precise amount of labor and expense which this machine will save, but we venture to hazard the opinion that a man and two apprentices will accomplish more in twelve hours than forty experienced journeymen can accomplish at the same work during the same period of time. It is withal one of those inventions which require no extraneous aid to bring it into immediate usefulness. The proprietor has commenced working it daily, and in a ware-room adjoining the machine he offers for sale its produce at from thirty to fifty per cent- less than the market price. This simple fact and the certainty that the work is in all its parts more perfect than that manufactured by hand, has produced a demand more than equal to the supply.

The machine is admirably well adapted to any sort of sawing that is usually done by hand or cross-cut sawing. Tenons, mitre joints, &c. are cut with the greatest precision. In all sorts of pannel work and small framing it will be very useful. It is peculiarly adapted to sawing regular and eccentric circles, such as felloes for wheels, chair tops, seats, legs, and backs, and circular blocks for brushes; and it saws chair tops and seats with great accuracy on a bevel.

- From the July 1834 issue of The Farmer's Register:

HAMILTON'S SAWING AND BORING MACHINE.

This machine is designed for sawing and boring wood or timber, and is claimed by Colonel Hamilton in his specification to be "an improvement in tha mode of sawing felloes of wheels, circular and curved segments, mitre joints, tenons, and also boring of felloes and hubs of wheels;" and "generally for sawing circular, curved, and plain surfaces. The machine is propelled by a two horse power steam engine. Animal or water power may be applied for the same purpose. The particular form required is sawed out of the timber with perfect accuracy and great expedition, by means of one or more thin narrow saws moving up and down. There is also belonging to this machine a horizontal saw for cutting segments of "circles, their proper lengths, and with proper inclinations for joints, tenons," &c. &c. Hubs of carriages are bored with perfect precision. All these operations are effected by the changing position of the material accommodating itself as it comes in contact with the saw or auger, so as to receive the exact form, inclination, &c. required. Every thing is done without marking or laying out, with mathematical accuracy by means of scales, which are distinctly laid down on the machine.

The machinery which guides and steadies the material in its movements may be readily varied, so as to form segments of wheels of greater or less dimensions; and the boring may also be more or less inclined. The scale indicates the exact position which the part of the machine that guides the material required to form a wheel,—for instance, of greater or less circumference: slats and legs of chairs may be made of various lengths, and thicknesses, and shapes, as fashion or utility may dictate.

This machine affords a happy specimen of labor saving, and may be advantageously applied to a variety of useful purposes. It occupies but little space, only a part of a small room. No skill is required in using it. A mere laborer, or a boy, can learn in a few hours to use the machine, and to produce the article as perfect as the most skilful machinist. Like many other labor saving machines, it performs that part of the labor which the accuracy and strength of the human, hand are incompetent rapidly, and with precision, to perform; it, in fact, does the work which is the most difficult and toilsome to the laboring manufacturer.

The expedition with which materials of small value, and with very little waste, are converted into articles of comparatively much greater value is entitled to particular notice. Chair backs sawed from our native curled maple are worth from eight to twelve and a half dollars per hundred.

By the aid of this machine, which costs only about three hundred dollars, a common laborer may do the work of twenty or thirty mechanics. The merit claimed by Col. Hamilton consists chiefly in the facility and accuracy with which the material is adapted to the saw, so as expeditiously and uniformly to produce the exact form which is wanted.

- Article in 1848-09-30 Scientific American.

- An 1857 article on the development of woodworking machinery by G. L. Molesworth says,

For sawing ship-timber, in curved forms, the saw invented by Mr. Hamilton, of U. S. America, is the most effective. The saw-gate of this machine is formed of hollow wrought-iron bars, so as to combine stiffness with lightness; in this gate there are two internal gates, so attached as to be capable of a transverse sliding motion along the external gate; to each of these internal gates a saw-blade is attached by buckles, which admit of their being turned on their centres, whilst in motion, by a forked lever of wood, which the workman applies to the back of the saw, to guide it along any required line which may be marked out on the timber. The oblique lateral motion is provided for, by the traversing inner gates and by the swivelling motion of the blade. The timber is attached by chocks at either end, turning on centres, so that the wood may be swivelled on its axis, by means of gearing, and thus enable the timber to be cut to any variable bevil, as it travels against the saw. Mr. Green invented an ingenious method of insuring accuracy of variable bevil, in this sawing-machine, obviating the necessity of trusting to the eye of the workman, and producing the required bevil from scale drawings. The machine is furnished with a small roller, which is put in motion by gearing, so that the travel of its periphery is proportional to the movement of the timber against the saws; a tracer is also attached, by gearing, to the swivelling chock of the log, so that if it is brought into any position with regard to the roller, it will indicate a certain amount of bevil given to the wood. A small diagram is drawn out on paper to a proper scale, and is wound round the roller, in the same manner as the steam-engine indicator diagram is usually done. The workman keeps the tracer, by means of a screw, on the lines of the diagram, as it slowly revolves, and the log will be cut to a variable bevil, corresponding proportionally to the diagram drawn out.

|