Manufacturers Index - Putnam Machine Co.

Putnam Machine Co.

Fitchburg, MA, U.S.A.

Manufacturer Class:

Wood Working Machinery, Metal Working Machinery & Steam and Gas Engines

Last Modified: Mar 18 2025 1:15PM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

|

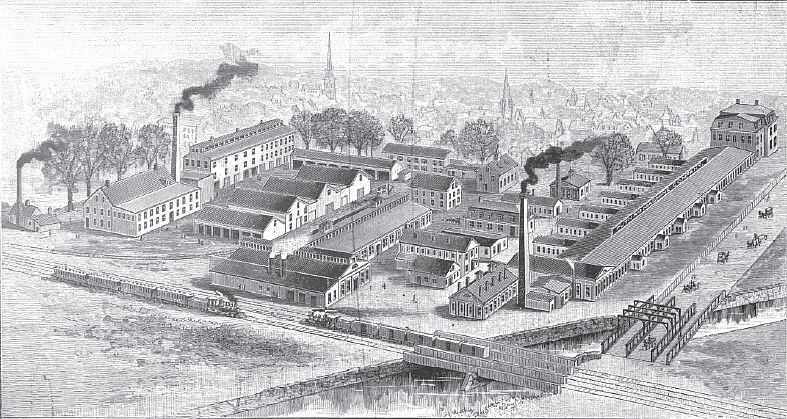

| Putnam Machine Company’s Works |

This business was founded in 1836 by John Putnam and Salmon Wilder Putnam as J. & S. W. Putnam Co., to make machine tools; they had been making metalworking lathes for at least a couple of years by then. By 1851 they were also making steam engines. The company was incorporated in 1854 as Putnam Machine Co., with Salmon Putnam as president, a role he maintained until his death in 1872. In 1886 the company absorbed Putnam Tool Co., which had been founded by Salmon W. Putnam's two sons. At some point, probably early in their history, they began making patternmakers' lathes, which are wood lathes similar in construction to early metalworking lathes. They also made drill presses. The manufacture of steam engines began in 1855. They were designed by Charles H, Brown, who left in 1863 to found his own company, C. H. Brown & Co. The company was taken over by Manning, Maxwell & Moore in 1913.

Information Sources

- The Massachusetts corporate registry database lists this company's first registration as 1856-12-04.

- The 7 November 1863 issue of Scientific American has the following note:

GUNS FOR MASSACHUSETTS—The Putnam machine company, of Fitchburg town, have contracted for the manufacture of the heavy guns for the coast defense of this State ; and are erecting buildings and machinery. A portion of the guns will be of the Blakely pattern, weighing from twenty to thirty tons each, and all of them will be rifled, and are designed to throw a projectile weighing from three to six hundred pounds. This company will also manufacture for the State a new pattern cast-steel rifle gun, designed by C. Burleigh, one of the Putnam machine company.

- The 13 February 1864 issue of Scientific American has an article on an improved friction pulley that had been patented by Charles Burleigh, the patent being assigned to Putnam Machine Co. "For more information contact E. C. Tainter, Worcester, Mass."

- The 15 April 1865 issue of Scientific American has the following tidbit:

BLAKELY GUNS MADE IN MASSACHUSETTS.—The Putnam Machine Company have completed at their manufactory in Fitchburg a couple of 11-inch cannon, of the Blakely pattern, which weigh upwards of 43,000 pounds apiece. The breech is clad with a thick steel jacket, and this jacket is encircled with steel rings, making a thickness of about 12 inches of solid steel around the castings. They are for the defence of Boston harbor and cost about $25,000 each.

- Salmon W. Putnam was granted an 1866 patent for an improvement to C. P. S. Wardwell's double-arbor tablesaw. Putnam's was only the second patent awarded (after Wardwell's) for such a saw, but we have seen no evidence that it was ever manufactured.

- 1869 Webb's New England Statistical Gazetteer,, pg. 241-242.

The oldest and most extensive manufacturing company here is the Putnam Machine Co., which was incorporated in 1858; capital, $40,000, since increased to $160,000. S. W. Putnam, president; B. Snow, Jr., treasurer; L. D. Bartlett, secretary. A new manufactory was built in 1866, located in the centre of the place, on Main street, on a track of land comprising 20 acres, owned by the Company. The main building is 469x90, 1 story, with office and wings attached, making the whole 625 feet in length. The office being 2 stories, all built of brick, besides numerous large and spacious buildings for foundries, machine shops, pattern and storehouses, &c., &c. They employ 250 men manufacturing steam engines, machinists' tools, planers, shafting, &c. A 70 horse engine of their own make supplies the power. They melt 7 tons of iron daily, manufacture all of their brass castings, and have every facility to make a complete establishment. The arrangement of the large building used as a machine shop is peculiarly adapted for economy of time, space, and labor. At regular intervals projects a small wing on either side, one used for setting up the machines after they are made, the other, directly opposite, as an office of the overseer of this department. There are 7 departments and 14 L’s, an arrangement which manufacturers will appreciate. A new office building is about to be erected, (1869) designed by S. W. Putnam, Esq., Jr., a son of the President of the company, who also planned the new building, which we have noted. The office will be 70 x 66 feet, 4 stories, including French roof, built of pressed brick, with stone trimmings; a large public hall will be in the third story, the second for the office, and the first for stores. The intension is to make this building equal to and office building in New England. This company is the parent of several similar establishments that have gone out from it, and which now rival it in producing reliable work, as well as for financial ability.

- The December 1872 issue of Manufacturer & Builder has an article on J. Greenwood's bolt-forging attachment for steam-hammers. This was Jeremiah Greenwood, an employee of the Putnam Machine Co., though so far as we know Putnam did not manufacture this item nor were they assigned the patent.

- Listed in the 1874 work, Wiley's American iron trade manual of the leading iron industries of the United States: "Salmon W. Putnam, President. B. Snow, Treasurer. General machinery, and machine tools."

- The Official Catalog of the 1876 International Exhibition lists "Putnam Machine Co., Fitchburg, Mass.—Machinists' tools, steam engines, Woodworth planers, water wheels, shfating, mill work, etc."

- The September 1876 issue of Manufacturer & Builder describes the metalworking machinery exhibits at the Centennial Exhibition.

The Putnam Machine Co., of Fitchburg, Mass., exhibit a number of tools embodying the latest improvements for accuracy and convenience. The material in the various parts is so distributed as to give the greatest strength and rigidity possible for the quantity used. An exhibit which attracted our attention particularly was a planing machine having a capacity for work 30 inches wide by 30 inches high, and is of unusual strength and power, being capable of doing the heaviest work without straining or injuring any of the parts.

- Article in the March 1885 issue of Bay State Monthly, available online as part of Gutenberg project. Here is the relevant portion:

Machinery takes the first rank among the manufactures of Fitchburg. The pioneers in this business here were two brothers, Salmon W. and John Putnam, who, in 1838, established the firm of J. & S.W. Putnam. In 1858 S.W. Putnam organized the Putnam Machine Company, which now has a wide and enviable reputation. Mr. Putnam was President and General Business Manager of the company until his death in 1872. Two of his surviving sons are now actively engaged in carrying on the business, Charles F. Putnam being President and Manager, and Henry O. Putnam Superintendent of the department in which special machinists' and railroad tools are made. There are six other departments devoted to special kinds of manufacture which are superintended by able men. Mr. Putnam's two other sons founded, in 1882, the Putnam Tool Company, located on Walnut street, of which Salmon W. Putnam is President, and George E. Putnam Treasurer, and is owned entirely by the Putnams. This company manufactures machinery, railroad and machine tools. The present location of the Putnam Machine Company, corner of Main and Putnam streets, comprising over twenty-six acres, was purchased in 1866, and the buildings were immediately erected at a cost of over $200,000. The works were built from plans designed by the late President, and are arranged with special reference to the variety of machines manufactured, consisting of railroad and machinists' tools, steam-engines, water-wheels, and shafting. They comprise machine shops, foundries and forges, and rank with the oldest and largest establishments of the kind in the United States.

The Putnams are descendants of Gen. Israel Putnam of Revolutionary fame.

- 1891 Inland Massachusetts Illustrated by Elstner Publishing Co., pgs. 130-131.

Charles F. Putnam, President; Salmon W. Putnam, Vice-President; Henry O. Putnam, Treasurer; George E. Putnam, General Superintendent—Offices Corner of Main and Putnam Streets, Fitchburg, Mass.

The history of the Putnam Machine Company embraces the first efforts at metal-working established in Fitchburg, when, in 1836, J. and S. W. Putnam began business for themselves. The company was incorporated in 1858 by D. W. Putnam, who was chosen president and business agent, which position he held until his death in 1872. The present works, located at the corner of Main and Putnam streets—the main machine shop building being 625 feet deep, by a frontage of 45 feet on Main street with seven large L's, foundries, etc.—were erected in 1866, and cover an area of fifteen acres, the entire plant being provided with the most approved modern machines and appliances for the expeditious and efficient execution of this class of work. In the production of railroad machine tools, steam engines, etc., this company has enjoyed the reputation, well sustained, of being one of the first-class builders of the world; and, although since its inception great improvements have been made in this line, it has been this company's constant endeavor to manufacture only such as at the time justly entitled them to their world-wide reputation. In 1866 the Putnam Tool Company (S. W. Putnam Sons) was consolidated with the Putnam Machine Company, and all the valuable patents and improvements in railroad machine tools, etc., built by that company became a part of the product of the Putnam Machine Company. By this consolidation, the addition of a new iron foundry 150 x 60 feet in dimensions, additional railroad turnouts, iron cranes, steam engines of greater power, replacing the older machinery throughout the works with the latest and most improved, now finds this establishment one of the most extensive and best equipped in the United States, with facilities for greater production than ever before in its history. A partial list of the products of this great industry will doubtless interest the reader. The company, however, publish a comprehensive illustrated catalogue, which is designed to give the fullest possible information upon the subject. As far as the limited space allows in this work, it may be noted that this company manufacture railroad machine tools and special metal-working machinery, steam engines, wood-planers, water wheels, mill work, shafting, radial drills, shaping machines, etc., engine lathes, iron planers, upright drills, transverse drills, hydrostatic presses, milling machines, gear cutters, bolt cutters, pulley lathes, car axle lathes, slotting machines, nut tapping machines, boring machines, pattern lathes, car wheel boxes, etc. Upon all of which the highest award was given this company by the United States Centennial Commission, at the international exhibition in Philadelphia in 1876. The location of this company's works affords them the very best shipment facilities, being on the direct line of the Fitchburg, Boston, Hoosac Tunnel and Western, Old Colony, and other important railroad connections. They have unsurpassed advantages for prompt and easy communication to all parts of the United States and foreign countries and for obtaining in Fitchburg the lowest possible through freight rates on bills of landing. Much more could be said of this great enterprise, both as to its facilities and honorable record. The personnel of this company comprise gentlemen of superior commercial ability and practical knowledge of the mechanical arts. The phenomenal success of the enterprise attests the truth of these statements. Their social standing also is of the highest order in this enlightened community by reason of the deep interest always displayed by the Messrs. Putnam in all that tends to advance the public welfare of this city and the social condition of their army of employees.

- The May 1895 issue of The New England Magazine has a history of Fitchburg, written by Joseph G. Edgerly. Its version of the company history is nearly identical to that in that March 1885 article in Bay State Monthly.

- The 1913-10-09 issue of The Iron Trade Review has the following news item.

Putnam Machine Co. changes hands

The entire capital stock of the Putnam Machine Co., of Fitcbburg, Mass, has just been purchased by Manning. Maxwell & Moore. Inc., of New York. The Putnam Machine Co. is the pioneer machine tool manufacturer of the country. The company was started in a small way in 1836 by Salmon W. and John Putnam. From a small beginning the company has grown until today its plant covers about 14 acres in Fitchburg. It produces heavy railroad machine tools, such as locomotive driving wheel lathes, coach wheel lathes, axle lathes, car wheel borers, hydrostatic wheel presses and metal planers and lathes of all sizes.

Of the old stockholders of the Putnam Machine Co., S. W. Putnam, son of the founder and himself a designer of wide reputation, and his son, S. W. Putnam 3d, will retain their connection with the company, which will retain the name of the Putnam Machine Co., and be operated on its own identity, as are the various other subsidiary companies of Manning, Maxwell & Moore, Inc. The stock which has hitherto been carried at 85 Liberty street, will be carried at the Jersey City Distributing Station, 446 Communipaw avenue, Jersey City, N. J., from which point shipments will be made. Manning, Maxwell & Moore have recently taken new offices of about 24,000 square feet, (double their present office quarters) on the twentieth and twenty-first floors of the building at 119 West Fortieth street, New York, which will be occupied shortly.

- October 1913 The Iron Trade Review, V53, 08, pg. 662.

Putnam Machine Co. Changes Hands

The entire capital stock of the Putnam Machine Co., of Fitchburg, Mass, has just been purchased by Manning, Maxwell & Moore, Inc., of New York. The Putnam Machine Co. is the pioneer machine tool manufacturer of the country. The company was started in a small way in 1836 by Salmon W. and John Putnam. From a small beginning the company has grown until today its plant covers about 14 acres in Fitchburg. It produces heavy railroad machine tools, such as locomotive driving wheel lathes, coach wheel lathes, axle lathes, car wheel borers, hydrostatic wheel presses and metal planers and lathes of all sizes.

Of the old stockholders of the Putnam Machine Co., S. W. Putnam, son of the founder and himself a designer of wide reputation, and his son, S. W. Putnam 3d, will retain their connection with the company, which will retain the name of the Putnam Machine Co., and be operated on its own identity, as are the various other subsidiary companies of Manning, Maxwell & Moore, Inc. The stock which has hitherto been carried at 85 Liberty street, will be carried at the Jersey City Distributing Station, 446 Communipaw Avenue, Jersey City, N. J., from which point shipments will be made. Manning, Maxwell & Moore have recently taken new offices of about 24,000 square feet, (double their present office quarters) on the twentieth and twenty-first floors of the building at 119 West Fortieth Street, New York, which will be occupied shortly.

- The 1914-04-30 issue of The Iron Trade Review has the following news item.

FITCHBURG, MASS—Manning, Maxwell & Moore, of New York, have taken over the Putnam Machine Co. Part of the old works will be razed and several new brick buildings built in the rear, The city council has voted $60,000 land damages to Manning, Maxwell & Moore, and when alterations and additions are done from 500 to 700 hands will be employed.

- The 1914-05-14 issue of The Iron Trade Review has a follow-up to the previous item.

FITCHBURG, MASS—Details regarding the building operations of Manning, Maxwell & Moore, who have bought the Putnam Machine Co., are as follows: There will be six new buildings. The main shop will be 220 X 300 feet, two stories, The foundry will be a brick building, 120 x 200 feet, and the blacksmith shop will be a brick building, 50 x 100 feet. The pattern shop will be four stories high, of brick, 50 x 100 feet. The office building will be a modern structure three stories, 50 x 100 feet, The power plant will be of brick, 48 x 84 feet, two stories. The buildings will all be fireproof. The contracts for building these structures have been awarded and work will be pushed as fast as possible.

- American Steam Engine Builders: 1800-1900 by Kenneth L. Cope, 2006 page 198

|