Machinery Photo Index

Manufactured/Badged by:

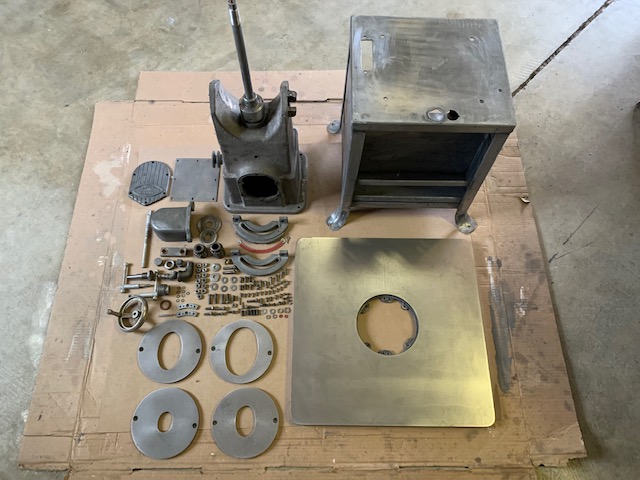

Boice-Crane Co.

Toledo, OH, then Gothenburg, NE, Chula Vista, CA

True Manufacturer:

Boice-Crane Co.,

Toledo, OH, then Gothenburg, NE, Chula Vista, CA

|

Machine Class: |

Wood Working Machinery |

|

Machine Type: |

Sander |

|

Machine Size: |

|

|

Submitted By: |

Matthew Warwick |

|

|

Description/Model: |

Oscillating Spindle Sander |

|

Date of Manufacturer: |

1940s |

|

Serial Number: |

N/A

|

|

Last Updated |

8/5/2024 4:33:55 PM |

|

Comments:

Source:

Taken with my iPhone

|

Comments:

Source:

Taken with my iPhone

|

Comments:

Source:

Taken with my iPhone

|

Comments:

Source:

Taken with my iPhone

|

Comments:

Source:

Taken with my iPhone

|

Comments:

Source:

Taken with my iPhone

|

|