|

Title: |

1880 Article-D. J. Murray Mfg. Co., Triumph Set Blocks & Head Works |

|

Source: |

American Machinist, 14 Feb 1880, pg. 5 |

|

Insert Date: |

7/3/2015 1:23:34 PM |

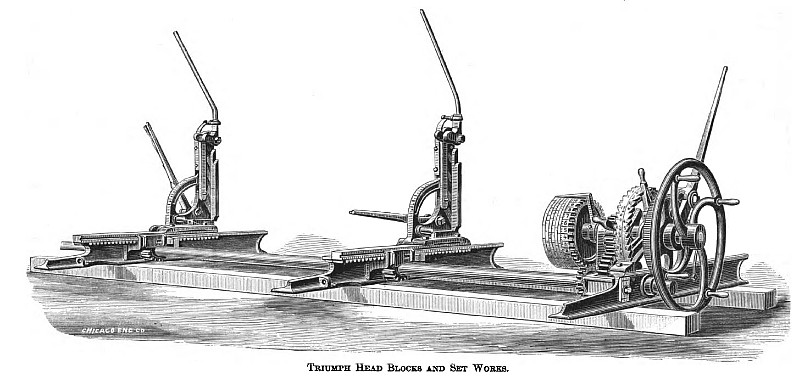

Improved Lumber Sawing Devices

In the prompt conversion of logs into lumber for building, the accuracy and durability of the machinery employed is of the highest importance. On this page we present an engraving of the Triumph Head Blocks and Set Works, made by D. J. Murray, Wausau, Wisconsin—devices which have gained a good reputation among lumber mills. The set works are placed on the head of the carriage, four feet from the first block, the setter to ride on the platform. The blocks are operated either by the lever or hand wheel. Each knee has an independent movement, and any one of them can be set ahead of the others by ¼ inch up to five inches, by a geared lever attached to the knee which is shown in cut, one knee set partly forward. This knee can be moved at the will of the operator without loss of time, which is very convenient in sawing tapering stuff or butt logs.

The dogs are opened by a cam movement, which is an important feature, as they gather the stock to the knee instead of crowding away. They hold a round log as well as the last board. The bits of these dogs are made of steel with a circular form on the lower side, and straight on the top. The dogs, after entering the cant, begin to recede or draw the lumber tight and firm to the knee till the last board is sawed and the dog withdrawn. The dog holds as well in the side as on the top of a cant, thus holding the bottom as well as the top. To saw two boards from a plank quickly with safety, it is drawn tight to the knee. This cannot be done with the long dog without bending the plank so as to saw both boards crooked. To spoil two boards in every log, is to spoil about one-tenth of the lumber, or more than one thousand feet daily from this cause alone.

There is usually a loss of time, some danger of accidents, and some waste and crooked sawing in finishing the log; but by the general arrangement of these blocks, the last part of the log is sawed just as easily and as well as the first.

These head blocks and set works are provided with a graduated scale making provision for side boards of all kinds of bill stuffs, with a ratchet indicator or quadrant mark to correspond with the scale, also an adjustable ring lever top combined with quadrant to gauge the throw of set lever; thus making the work so plain that any man who can read figures can set the machine with either hand wheel or set lever, without loss of time or waste of stock.

The joint set lever is pivoted above the ratchet by means of a bolt passing through the upper and lower half of lever forming a joint in the lever. The lower end of the upper half of lever is the pawl that engages the ratchet. This device enables the lumber to be cut by variations of 1/16 of an inch, from "commons" to "uppers" and from "scant inch" to "plump inch." It can be varied for thick and thin saws, also for thicker grades of lumber by means of a simple trip device connected with a set lever. A recent improvement in these blocks enables the operator to set every twenty-fourth of an inch of the scale with the same rapidity and reliable accuracy that each particular size was set heretofore. All parts are made interchangeable by means of standard steel gauges. |

|

1880 D. J. Murray Mfg. Co., Triumph Set Blocks & Head Works

1880 D. J. Murray Mfg. Co., Triumph Set Blocks & Head Works

|

|