|

Title: |

1880 Article-Curtis & Co., Felloe Sawing Machine |

|

Source: |

American Machinist, 03 Jan 1880, pg. 7 |

|

Insert Date: |

7/2/2015 12:51:05 PM |

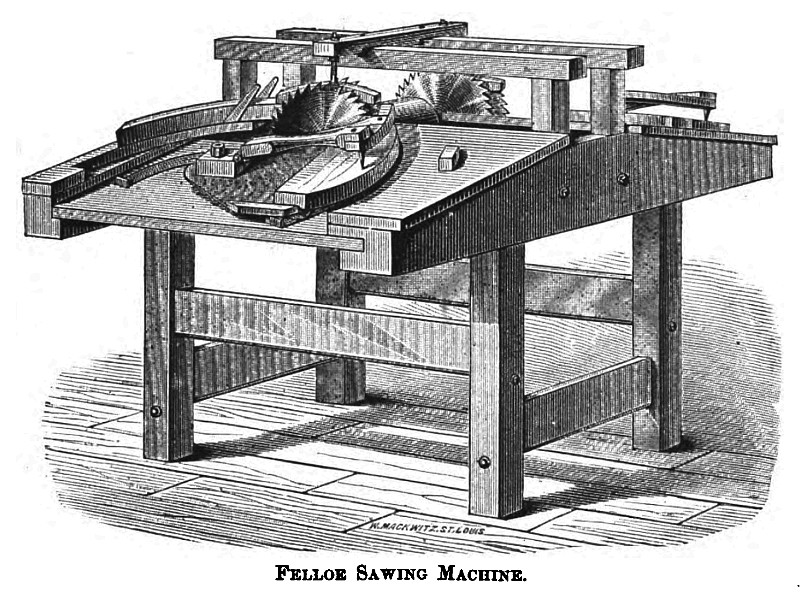

New Felloe Sawing Machine

Among the labor-saving machines used in wagon making none perform a more important part than those for felloe sawing. We illustrate on this page a recently devised machine for felloe sawing, manufactured by Curtis & Co., St. Louis, Mo., which has some superior features.

Its general construction may be seen at a glance. It consists of a mandrel with pulley and boxes, four concave saws, two of which are on one end of the mandrel to cut felloes for the front wheel, and two on the other end to cut felloes for the hind wheel, with washers between saws to allow the cutting of different thicknesses as desired.

The frame is constructed of the best seasoned material, and in the most substantial manner, each end of which is provided with Middlebrook's Improved Revolving Iron Table, placed on rollers, and revolving on an iron track immediately underneath. On this the timber to be sawed is placed, and fed to the saws with but slight exertion.

With his machine the operators can cut from 5,000 to 5,500 perfect felloes in ten hours, with less than half the labor required to perform the same work on the old style solid table. The pulley, 8x9 inches, should be driven by an eight or nine inch belt, and run about 2,500 revolutions.

The machine is not expensive, and is said to work with the highest satisfaction. |

|

1880 Curtis & Co., Felloe Sawing Machine

1880 Curtis & Co., Felloe Sawing Machine

|

|