|

Title: |

1878 Article-Ransomes & Sims, & Head, Portable Steam Engine |

|

Source: |

International Exhibition at Paris, 1878, pgs. 158-159 |

|

Insert Date: |

2/16/2015 9:59:20 PM |

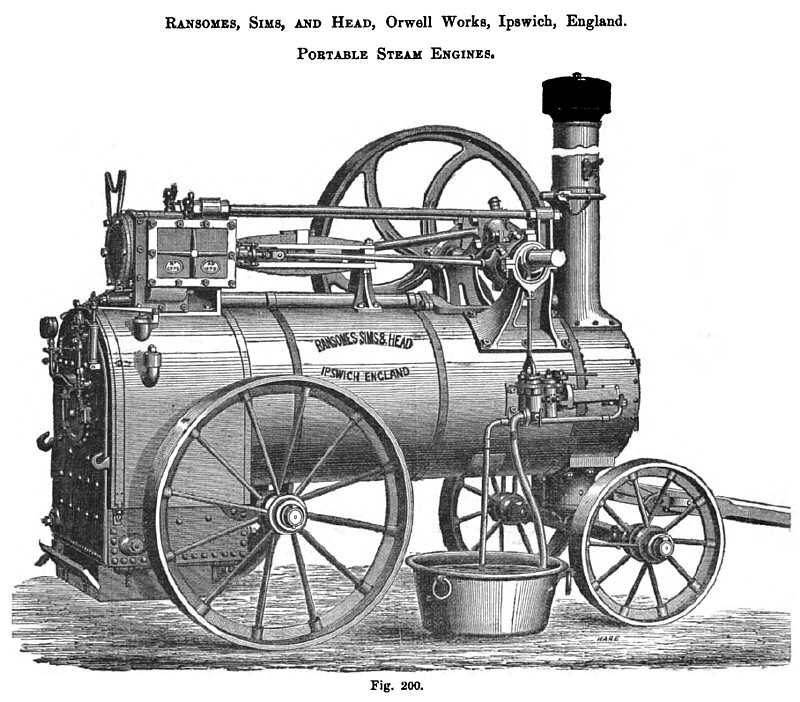

The engine shown in Fig. 200 is of the single cylinder, non-expansion class, and is fitted to burn coal, wood, or peat, the firebox having a large grate and heating surface. The boiler is of best English plate, the riveting being entirely done by hydraulic machinery, and the average working pressure amounting to 80 lbs. per square inch. Before leaving the works the boilers are submitted to a hydraulic test of 140 lbs. per square inch. The barrel and firebox shell are covered with lagging strips to prevent loss of heat by radiation.

The engine proper is placed on the top of the boiler. The cylinder is jacketed throughout, and the valve chest is accessible for repairs both from the top and side, thus allowing the port faces to be scraped up without removing the cylinder from the engine.

The crank shaft is carried on two cast-iron brackets, firmly bolted on to the cylindrical part of the boiler. These brackets are stayed to the cylinder by means of two strong wrought iron stays; one end of each stay is bolted to the top of each bracket, which are elongated so as to make them the same height as the cylinder, and the other ends are attached to strong lugs cast on the cylinder. These stay rods, which are screwed up when the boiler is hot to allow for the expansion, serve to steady the working parts of the engine, and to prevent that vibration often felt when an engine is doing the maximum amount of duty.

In the general arrangement, the principle of moderately high piston speed with a medium fly-wheel has been preferred to a long stroke and slow speed with a larger fly-wheel. The reason why this system is adopted is that the motion of an engine at a high speed is more uniform, and is not liable to be so easily affected by the sudden shocks due to great variation in the load. The average piston speed is from 280 to 300 feet per minute, the number of revolutions of the fly-wheel from 140 to 150 per minute; the speed of the periphery varying from about 2,000 to 2,500 feet per minute, according to the size of the engine. The bearings of the crankshaft, connecting rod, &c, are large and of good length, in order to distribute the strain over a large surface.

The slide valve and cylinder ports are of the ordinary locomotive type, arranged to cut off about one half of the stroke, with about 7/8-inch lap and 3/16-inch lead. The eccentric is attached to the crankshaft through a disc, and its movements can be easily reversed. The pump is continuous in its action; the cock for regulating the supply into the boiler is placed in the discharge pipe instead of in the suction pipe; and when it is required to pump water into the boiler this cock is shut, but when the water is raised to its proper level in the boiler, the cock in the discharge is opened, and the water is pumped back into the tank or reservoir. The inlet passage of the water from the pump to the boiler can easily be cleaned out, by unscrewing a brass screw, placed in the pump and communicating with the passage, thus rendering the valves less liable to stick and preventing, in great degree, the faces from being scoured when using muddy water.

The expansion engines are similar in general design to the engine just described, the boilers evaporating about 8 pounds of water for every pound of coal consumed, the usual proportion of heating surface being 15 square feet of tube surface, .60 to .75 of a square foot of grate surface, and 2.75 to 3.0 square feet of fire box heating surface, per nominal horse-power. The consumption of fuel is about 4 lbs. of coal per effective horse-power per hour.

In these engines the feed pumps are double, one being employed for pumping cold water into the heating reservoir in the smoke box, and the other for injecting the water from this reservoir, where it is raised to a temperature of nearly 212°, into the boiler. The slide valves consist of one large double-ported valve, with a fixed travel over the cylinder parts; and a second small gridiron valve, which regulates the admission of steam into the cylinder, and cuts it off to any part of the stroke that may be desired up to one-half. The two valves are worked by separate eccentrics. The larger valve has a lead of 3/16- in. and a lap of 1/2 in., and is moved by the inner eccentric This eccentric is fixed to a disc on the crank shaft. The small, or cut-off valve, is connected to the outside eccentric, which is loose on the shaft and kept in position by a bolt fixed to the inner sheave and sliding in a slot in the outer sheave. When the load on the engine is increased or diminished, and it is required to admit the proper amount of steam to accomplish the work with the smallest consumption of fuel, the expansion sheave is shifted round so that the pointer is on the line with the marks on the sheave indicating the exact point at which the steam will be cut off in the cylinder, and consequently the amount of expansion to which it will be subjected. In addition to this expansion slide these engines can be fitted with an automatic expansion governor, that has been found very useful in cases where the work is rapidly and frequently thrown on and off. The governors are of high speed, with light balls, the range of which is regulated by a spring. The connection with the throttle valve is adjustable by means of a quadrant, and the valve itself can be examined by removing a small cover, screwed on the slide lid. By the action of this governor the exact quantity of steam is admitted into the cylinder in the ratio required by the load on the engine, by closing the induction port immediately the requisite amount of steam required by the engine when it is performing a certain duty has entered the cylinder.

Prices, without expansion gear.

Single-cylinder, 4 horse-power ... ... £150

Single-cylinder, 8 horse-power ... ... 210

Single-cylinder, 10 horse-power ... ... 240

Double-cylinder, 10 horse-power ... 265

Double-cylinder, 14 horse-power ... 340

Double-cylinder, 20 horse-power ... 450

The expansion gear can be added at a cost of about £4 per horse-power. |

|

1878 Ransomes & Sims, & Head, Portable Steam Engine

1878 Ransomes & Sims, & Head, Portable Steam Engine

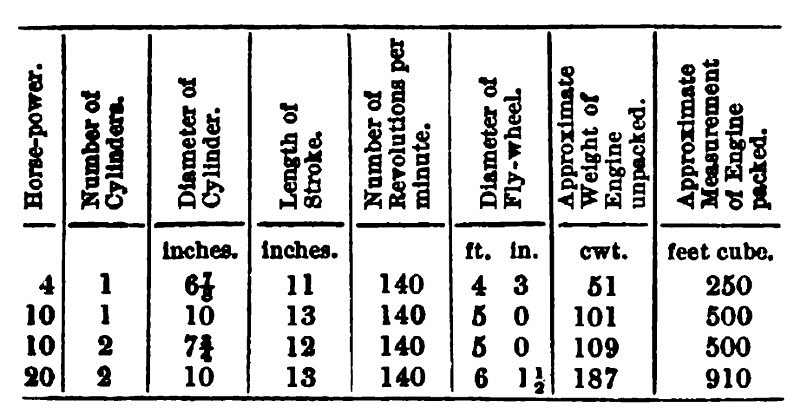

The following table gives the approximate weights, dimensions, and measurements.

The following table gives the approximate weights, dimensions, and measurements.

|

|