|

Title: |

1878 Article-Marshall, Sons & Co., Single Cylinder Portable Steam Engine |

|

Source: |

International Exhibition at Paris, 1878, pgs. 155-156 |

|

Insert Date: |

2/13/2015 9:57:26 PM |

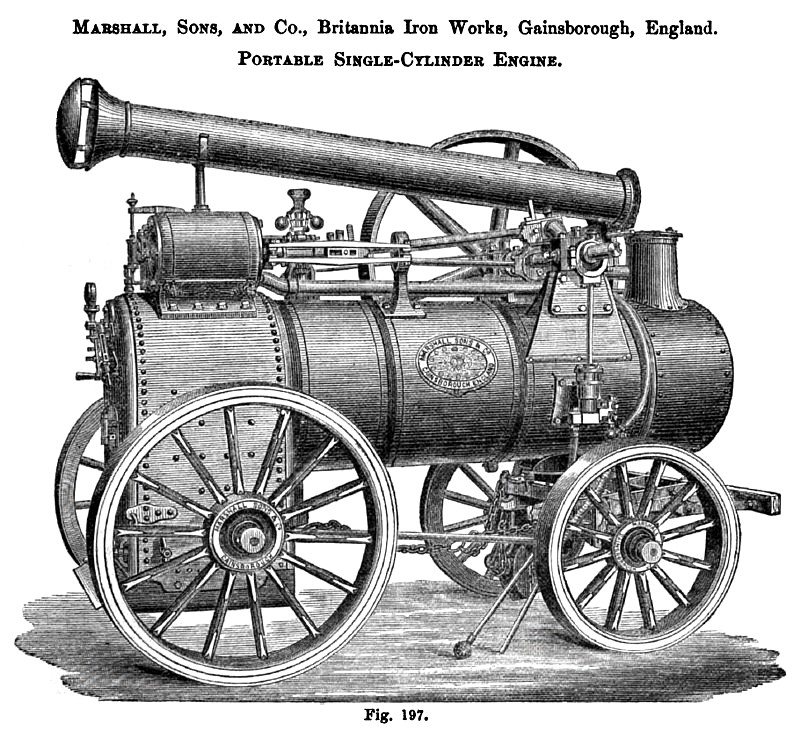

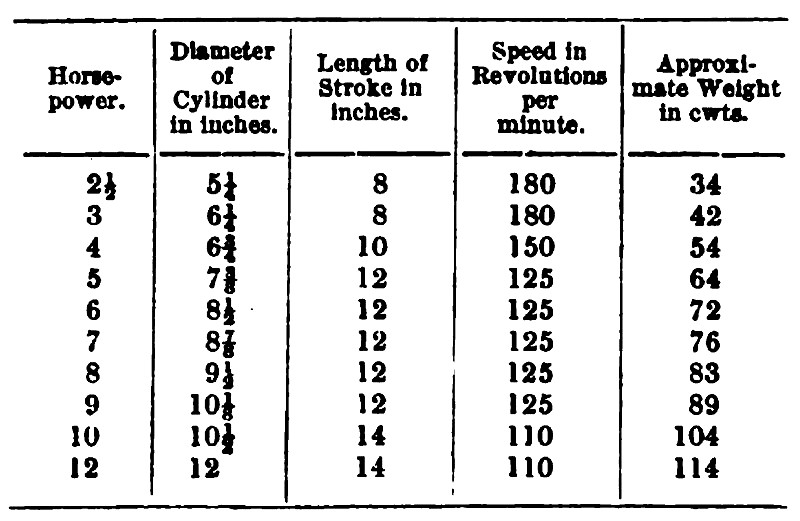

The above represents one of the improved single-cylinder engines. The cylinder is made of cold blast iron, with the outer barrel and valve chest in one casting, the inner or working barrel being a separate casting of special hard metal, and is tightly forced into the outer casting, which' thus forms a species of jacket. In engines of 10 horse-power and upwards the cylinder flanges are extended to each end of the cylinder, as well as to the sides, so as to give a large bearing surface on the boiler. The areas of the fire box and grate are proportioned to suit the kind of fuel the engine is required to

burn. In the construction of the boiler angle iron is entirely dispensed with, all the plates being flanged by hydraulic machinery, the edges then being planed, or turned in the case of the smoke box tube plate, and the riveting performed by hydraulic power. The crank shaft brackets are of wrought iron, and are fixed by a double row of rivets to the boiler, on which they have a large bearing surface, and are constructed so as to conduct but little or no heat to the crank shaft bushes, which are carried in a metal casting, bolted to the top of the brackets, as shown in the engraving.

The crank shaft is bent from a single bar without welding, and is arranged so as to give off the power from either side of the engine, or from both sides at once, there being sufficient length to fix pulleys at each end. The piston and valve rods are of steel. The slide bars are of cast-steel, and so arranged that, by removing thin brass washers from between the top and bottom bars, they can be readily adjusted, if the slide block should be worn.

The cylinder lubricator is not put on the cylinder cover, as is generally done, but on the top of the steam chest above the steam admission valve, and the oil dropping on to this valve is carried by the steam on to the slide valve, and into the cylinder on both sides of the piston. All the engines manufactured by this firm are fitted with an equilibrium steam admission valve, acted upon by a cross-arm quick-speed governor, which is very powerful and sensitive, and far more durable and reliable than the governors with large balls and ordinary throttle valve, the regular action of which is hindered by the counter pressure of steam. These engines are also fitted with a variable expansion and reversing eccentric, vertical and continuous acting force pump, and efficient feed water heater; the latter is attached to the steam exhaust pipe in such a manner that the condensed steam in the same goes straight down the water heater pipe into the tank, and the steam passing out of the cylinder will have a free passage into the chimney. The engines are provided with the usual fittings—as water gauge, gauge cocks, safety valves, safety fusible plug in fire box, steam whistle, blow-off cock, firing tools, tube brush, spanners, waterproof cover, &c., and, if required, a steam jet. A mud collector is fitted underneath the barrel at the fire box end.

Price.—6 horse-power £180; 8 horse-power £210. |

|

1878 Marshall, Sons & Co., Single Cylinder Portable Steam Engine

1878 Marshall, Sons & Co., Single Cylinder Portable Steam Engine

1878 Marshall, Sons & Co., Single Cylinder Portable Steam Engine (Specifications Chart)

1878 Marshall, Sons & Co., Single Cylinder Portable Steam Engine (Specifications Chart)

|

|