|

Title: |

1873 Article-Richard Garrett & Sons, Straw Burning Portable Engine |

|

Source: |

The Engineer Magazine, 22 Aug 1873 pg. 118 |

|

Insert Date: |

1/22/2015 8:27:02 PM |

It appears that the desire manifested to use straw as fuel for portable engines is extending. Not long since we illustrated a straw-burning portable engine by Messrs. Ransomes, Sims, and Head, of Ipswich; and Messrs. John Fowler and Co., working under the same patents, have fitted up two fine ploughing engines to work with straw, which have been tested with great success.

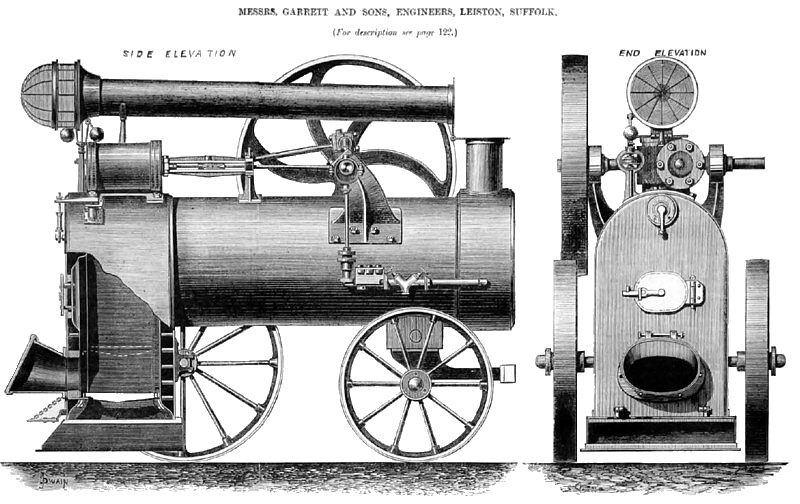

Messrs. Garrett and Sons of the Leiston Works, Suffolk, were in the field some time ago, and took out a patent dated November 15, 1871 for burning straw, as a communication from M. Paul Kotse, of Perth. The engine we illustrate at page 118, exhibited at Vienna, is constructed substantially in accordance with this patent. Very little explanation in necessary to make the arrangement quite intelligible. The furnace, capable of being fitted with the ordinary grate for burning coal, as shown by dotted lines; this grate is made removable in order that the furnace may receive another grate, as shown, for burning straw and other light combustible matters. In front of this second grate and on a level therewith is a spout through which the straw is introduced to the grate; this spout is closed air-tight by a hinged door, and forms in fact a kind of hopper extension of the furnace, the capacity of which is greatly enlarged to enable it to contain a proportionate quantity of the light fuel. The water jacket of the boiler is carried sufficiently far below the level of the straw grate, as shown, to permit of the calcareous and other deposit from the water taking place

below the efficient heating line of the fire and to protect the walls of the furnace. The furnace when arranged to burn straw, instead of terminating in an ashpan, as shown by dots, is made open at bottom to allow of the ashes being discharged into a pit dug in the ground for the purpose of receiving the ashes, the ashpan being for this purpose removed. When the engine is brought over such a pit, access of air through the ash-pit to the furnace may be prevented by means of loose covering plates, and by throwing up a mound of earth round the bottom of the furnace. A regulated supply of air can be admitted through a damper provided for the purpose below the straw-grate, and in front of the ashpan extension of the furnace, in which extension is slidden into and out of place and is supported by flanges, as shown. When using the furnace as a straw burning furnace, the door by which fuel is admitted to the fire-bars is kept closed to prevent the in-draught of cold air above the fuel.

As regards the efficiency of this apparatus we may quote the following extracts from a letter written to Herr Kotso, the inventor, by Herr Ludwig Von Karolzi:—"I," writes Herr Karolzi, “have had the straw burning engine these two years constantly in use, and drove my mill of two pairs of stones, as long as my stock of straw lasted, by straw firing, and the thrashing machine as long as the thrashing was done, constantly with straw fire only; even in some cases where there was a stock of old chaff, useless for any other purpose, or maize straw, I burned this material with great success. In regard to the proportion of work done by the engine to the consumption of fuel, you can judge from the following facts: I was threshing 400 mandelu (mandelu equals 15 sheaves) daily, and used one load of straw of 20 cwt., that is about 3 per cent of the thrashed straw; the value of this straw is in our country two florins (equal to 4s.). I was grinding 120 cwt. of corn into flour and wanted for firing two loads of straw of 40 cwt., the value of which is about four florins of this straw is in our country two florins (equal to 4s.). I was grinding 120 cwt. of corn into flour, and wanted for firing two loads of straw of 40 cwt., the value of which is about for florins(equal to 8s.) I thrashed as a trial, 400 mandelu, and required 9 cwt. of coal brink: from Funfkirchen, which cost about 1fl. 5 kr.per cwt., altogether say 9 fl. 50 kr. I ground 144 cwt. corn, and wanted 24 cwt. of the same coal(peat coal), which cost per cwt.1f. 05 kr. = 25fr. 20 kr. Therefore for the same work in the one case, (i.e., for thrashing), 20 cwt. straw was equal to 9 cwt. coal; therefore 1 cwt. straw = 0.45 cwt. coal. At the mill I was able to do more work with coal, but even here the proportion of 40 cwt. straw to 10 cwt. coal, say 1 cwt. straw to 0.45 cwt. of coal, is favourable enough to show that in employing your engine, 1 cwt. straw is like 0.36 cwt. of coal, in the average or in regard to price, 1 cwt. straw, 10 kr.—-2½d.; 0.36 coal, 38 kr.—9d. The coal cost, therefore, nearly four times as much as the straw for the same work.

My engine enjoys, as I state with pleasure, a great reputation in the whole district, so that I never am obliged to look after, or ask the parties for thrashing, but they come on their own account. I have, as the parties publicly state, to thank the excellent saving of time and money, in consequence of the straw firing, for this. Facts are stubborn things; a proof of this is that there are already in this short time, within a distance of a few miles, five of your straw-burning engines in activity, and are competing with me. As you see, I can only give you good news, and should conclude my writing with these few words, that I never had the least difficulty either in the treatment or working of the locomotive with straw for straw firing. You have made the whole process of firing your locomotive by straw quite in accordance with the method the farmer employs in firing his baking and warming stoves. He stands before the hopper-like opening, on the lower part of the locomotive, with a long fork fastened on a with the method the farmer employs in firing his baking and warming stoves. He stands before the hopper-like opening, on the lower port of the locomotive, with a long fork fastened on a long wooden handle; as soon as he thinks it necessary to get the straw into the box, which he must know at a glance at the fire-box and the pressure gauge, he puts his fork into the heap of straw a few feet distant from him, and gets a quantity of 3 lb. to 4 1b., shakes this properly whereby the straw, which is perhaps too damp falls down, and puts the dry and useful straw in a loose state by his fork, into the fire-door. At the some time he observes the condition of the straw previously in process of consumption, and shakes the cinders, if it appears necessary with his fork to prevent the accumulation of slag, which is as troublesome when burning straw as household coal, and on the removal of which depends the whole firing. An essential point in your engine for practical use is the top fire-door intended for coal fire. The same must, on firing with straw, be sometimes opened in order to remove by an ordinary broom the cobweb-like cinders which are raised by the draught, and settle down on the mouth of the fire-tube that is to prevent the flames to come into direct contact with the tube plate.

“As you see from this, the practical employment of your engine shows things of which, perhaps, you did not think at all and which will cause you to avoid any alteration perhaps already intended. Since I find the introduction of your straw humor to be in the interest of agriculture, I leave it to you to send this letter to Messrs. Garrett's for consideration, and to regard this letter as a public one in every respect."

Image courtesy of Grace's Guide.

http://www.gracesguide.co.uk/File:Im1873EnV36-p118.jpg |

|

1873 Richard Garrett & Sons, Straw Burning Portable Engine

1873 Richard Garrett & Sons, Straw Burning Portable Engine

|

|