|

Title: |

1887 Article-P. Pryibil, Re-Sawing Band Saw |

|

Source: |

The Woodworker, V6 #9, Nov 1887, pg. 12 |

|

Insert Date: |

1/5/2015 8:43:52 PM |

|

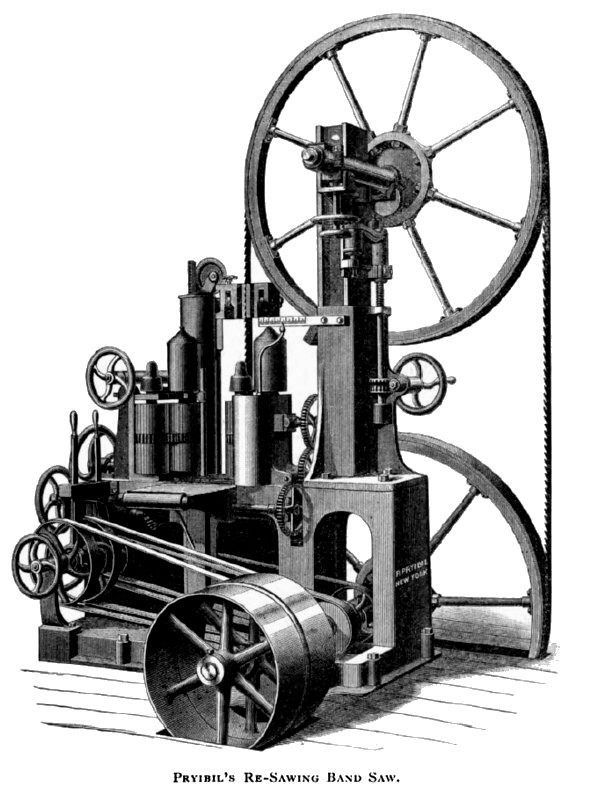

This machine will saw from 12,000 to 15,000 feet per day of ten hours, making a kerf of only 1-16th of an inch, or less, and getting from 1-inch stuff two pieces thick enough to make two 3/8 panels after being planed on both sides. The importance of this point, especially when costly woods are used, is apparent when it is considered that with many machines such a result can be reached only by the use of 1¼-inch stuff. The feeding is effected by four strongly geared live rolls and two smaller idle rolls, the latter being so arranged as to guide the last end of the stuff after it has passed the first pair of live rolls, and until the finish of the cut. Strong springs behind each of the bearings of the two feed rolls at the left of the saw hold these rolls up to the work and enable them to yield to all inequalities in the stuff. As either top or bottom of these rolls can yield independently or both together, a good bearing against the work is always insured, and the stuff is compelled to follow the guidance of the non-yielding rolls. Four rates of feed are provided, any of which can be thrown into or out of operation by moving a hand-lever and without belt shifting. The saw runs between hardened steel plates filled with dogwood plugs, with the end grain in contact with the saw, and each plate can be accurately adjusted by a single screw. The back of the saw bears against hardened steel rollers, which can be adjusted sideways as they become grooved from use. These rollers are also adjustable to different widths of saws, and are provided with self-oiling bearings. The upper guide is counterbalanced by a weight hidden in the guidepost, and is geared to a hand-wheel by means of which its height can be easily varied. This hand-wheel, the levers for changing the feed, and the hand-wheels for setting the feed-rolls, are all accessible from the operator's position, and can be manipulated while the machine is in motion. The rims of the wheels are of bent ash, strong and light, and they overhang the ends of the bearings, which latter are self-oiling. The over-hanging feature is quite important, effecting as it does, the same result that some makers obtain by the use of a clumsy and complicated arrangement of outside bearings. The upper shaft can be angled while the wheels are in motion. It is carried on a slide, cushioned upon an adjustable spring, which maintains a proper tension on the saw throughout all variations of length due to change of temperature. This renders the saw much more secure against breakage than the weights commonly used for this purpose, as the inertia of weights prevents them from yielding quickly enough when a chip gets between the saw and the wheel, the result being a broken saw. To provide doubly against such an accident, a wooden block is so fitted in the throat between saw and wheel as to catch all chips and saw-dust and discharge them beyond the rim. The lower wheel is kept free from accumulations of saw-dust by a scraper, and the upper one by a brush. The body is a box-shaped casting, in one piece, very strong and rigid, and it insures the perfect alignment of all the parts. The loose pulley is self-oiling, one inch smaller in diameter than the tight pulley, to slacken the belt when the machine is stopped, and it is provided with a step at the inner edge to cause the belt to shift easily. Fitted feed belts are furnished, and every machine is tested before leaving the factory. Weight of machine complete, about 6,000 pounds. Diameter of wheels, 60 inches. Driving pulley, 22 to 30 inches diameter, as ordered, for 8 inch belt. Speed, 400 to 450 revolutions per minute. Thickness taken between feed-rolls, 17 inches. Height of stuff that can be sawed, 30 inches. P. Pryibil, No. 461 to 467 West 4oth Street, New York, is the manufacturer. Mr. Pryibil guarantees that the thinnest four-inch band saw blade ever made has been run successfully upon this machine. |

|

1887 P. Pryibil, Re-Sawing Band Saw

1887 P. Pryibil, Re-Sawing Band Saw

|

|