|

Title: |

1896 Article-A. Ransome & Co., Log Band Saw |

|

Source: |

The Engineer Magazine, 13 Mar 1896 pg. 277 |

|

Insert Date: |

12/20/2014 9:53:20 PM |

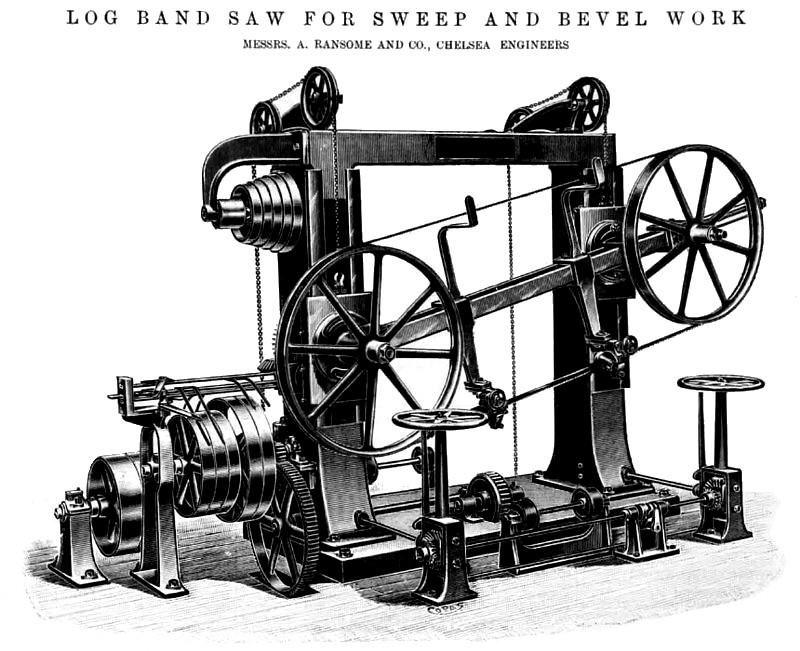

This machine, illustrated by the above engraving, was designed and constructed for Messrs. Harland and Wolff, of Belfast, by Messrs. A. Ransome and Co., Chelsea, for carrying out special work that is costly and tedious to do by any other means. It is specially arranged for cutting curves and bevels in logs and spars of any length up to 60ft., and of any diameter up to 36in. The machine, when its pulleys are in their normal position, is of the horizontal type of band saw, but to effect the necessary sweep and bevel cutting, each pulley can be lifted or lowered independently of the other, whether the machine is actually in the cut or not. Thus the blade will follow any curves or bevels that may be marked on both sides of the log. The saw pulleys are 48in. in diameter, and are arranged to rise and fall b hand wheels on either side of the machine, thus bringing them under perfect control of the attendants, one of whom would be stationed at each hand wheel to follow the necessary sweeps, bevels, and curves required at either side of the piece being sawn. The slide carrying these band pulleys is counterbalanced by suitable weights, thus making the motion easy and rapid.

Practically, the whole of the machine being above the floor line, but little expense is required in the way of foundation. The traveling table is 60ft. long, this length covering spars and logs of the maximum ordinary lengths used in shipbuilding. It is made up of malleable iron plates ½in. thick. These plates are carried on three longitudinal beams, two of which run on suitable rollers, the underside of the third or centre one being fitted with rack. As a rule, the pieces lie on the table themselves without any fixing, being held in position

by their own weight, but for spars and logs of uneven thickness, a series of dog-screws are required to prevent such pieces from moving while in operation. The table is not shown in our engraving. It is carried in the usual way, and is moved by the cog-wheel which can be seen in the centre of the space between the two standards. The feed motion is arranged with five different rates of speed. The saw guides are specially made so that the blade can be canted in the necessary direction, according to whether the cut is leading down or up in the sweep or curve. The weight of this machine is 13 tons. The average indicated power required is about 15-horses. The pulleys driving it make 400 revolutions per minute.

Image courtesy of Graces' Guide. |

|

1896 A. Ransome & Co., Log Band Saw

1896 A. Ransome & Co., Log Band Saw

|

|