|

Title: |

1876 Article-Otto Gas Engine Works, Langen & Otto Gas Motor |

|

Source: |

Scientific American, Supplement, V 2 #49, 02 Dec 1876, pgs. 420-421 |

|

Insert Date: |

12/19/2014 7:33:39 PM |

This is a Prussian exhibit, deserving of careful attention of all who desire to avail themselves of a good substitute for small steam engines.

An explosively acting gas-engine is in reality a gun, discharging shots whose force should be fully realized and converted into steady work. The "gunpowder pile-driver" is an instance in which explosive force is converted into work, and in which that explosive force would be fully utilized were it not that the bore of the gun is so short as to allow the gases to escape at a very high pressure. But in the gunpowder pile-driver the full recoil of the gun is at once realized and converted into work, and the force expended in driving the piston or shot to the top of the shears is all (less a trifle for friction) returned and used when that shot falls. The gunpowder pile-driver is, in fact, a single-acting explosive engine, with an " exhaust " of 500 lbs. pressure to the square inch.

If, now, it were possible (1) to exhaust at atmospheric pressure, (2) to prevent waste of force in a ruinous heating of the parts of the machine, and (3) to apply the explosive force to producing steady rotary motion, the gas-motor problem would be far towards a complete solution.

(1) To exhaust at a lower pressure, requires merely a lengthening of the gun. In the gunpowder engine the volume of the charge is increased by explosion from one to 2000, hence the length of the stroke would have to be at least 2000 times the depth of the charge. The substitution for gunpowder of a gaseous explosive, in which the products of explosion are but eleven times the volume of the charge, would necessitate a length of stroke but little more than eleven times the depth of the charge.

(2) To prevent the heating of piston and cylinder, the action of the explosive force upon the piston must be unimpeded. The full amount of force is then expended in the increase of volume of the gases, and the direct propulsion of the piston.

(3) To apply the great explosive force directly in actuating ordinary machinery, is impossible. To utilize on the return stroke the force of the explosion stored up in the piston, is possible, but necessitates a special mechanical adaptation for its accomplishment.

In other words, the following features should, and it is claimed in this device do, find place in an economical explosion engine: 1, a free piston ; 2, great length of cylinder ; 3, the entire abandonment of the crank (a device of itself, irregular in action and unsatisfactory in result, even in its use with a slow and steadily expanding motive agent, as steam).

The devices for aspiration, explosion and exhaust, may best be understood from the accompanying diagrams:

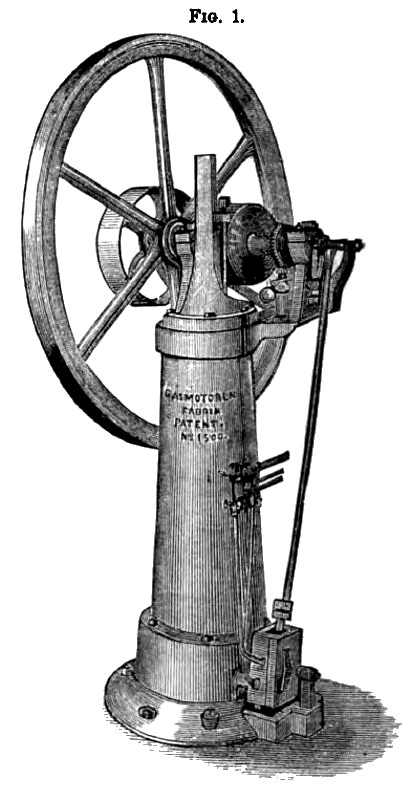

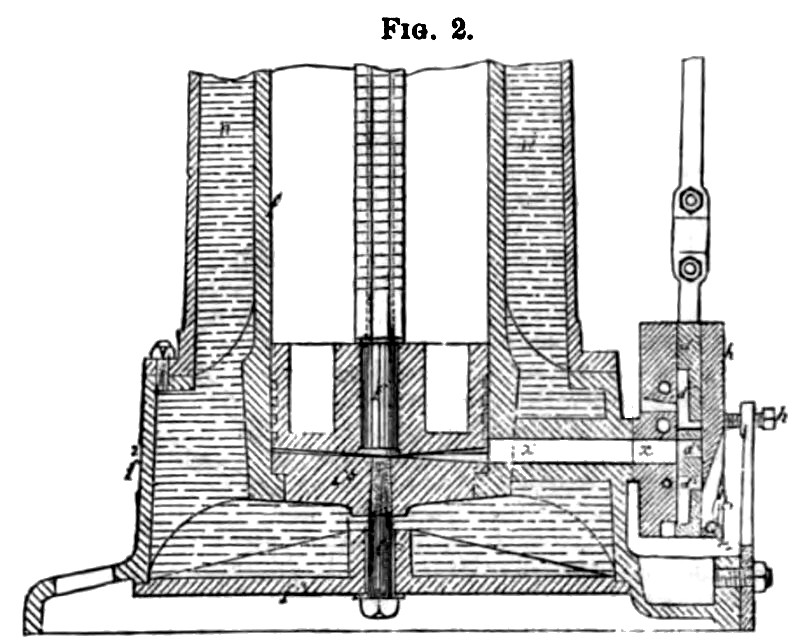

The engine is shown in elevation, in Fig. 1. Fig. 2 is a vertical section of the lower portion through the slide-valve. The piston f, being lifted about 1/11th the length of stroke, gas and air are thereby drawn in through the channel x. The power to effect this movement is obtained from the momentum of the fly-wheel.

"On the igniting of the charge, the piston flies freely up to the top. As it ascends, the plenum caused by the explosion changes to a partial vacuum, reaching 22" of mercury at the top of the stroke, and thus the motion of the piston is quickly reversed and the down-stroke is performed under a pressure of about 11 lbs. per square inch, derived from the atmosphere, this driving power being communicated through the rack and toothed wheel to the shaft. When the piston has reached within a given distance of the bottom, the vacuum, which has been gradually decreasing, is again changed to a plenum, and the weight of the piston and rack expels the burnt gases during the last few inches of the stroke, thus completing the cycle of operations."

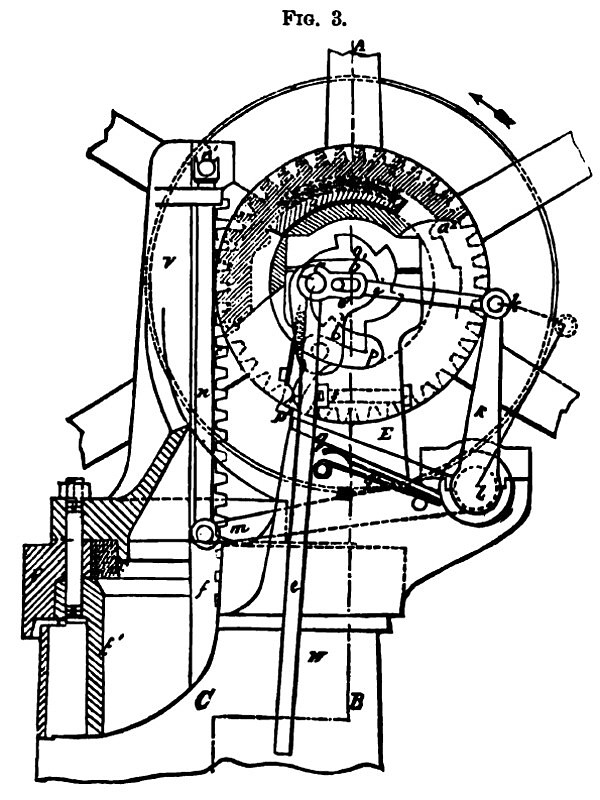

The friction clutch used to connect and disconnect the piston-rod rack with the driving-shaft, is shown in detail in Fig. 3, which gives a partly sectional view of the upper portion of the engine, in a vertical plane at right angles with the piston, an intermittent motion is provided for lifting the piston, which is started at the right moment by a tappet fixed to the rack.

The exhaust port being open during the entire down-stroke, there is a valve provided in the exhaust-pipe, preventing the atmosphere from entering the cylinder and destroying the vacuum, but yielding when the weight of the piston expels the burnt gases at the end of the stroke. By this arrangement the piston strokes would follow each other without any delay, if a common governor were not controlling a second stop, keeping the pawl P from falling into gear with the ratchet-wheel, moving the slide-valve, and aspiring gas into the cylinder.

This is one of the most important features of the engine. To take an example of its effect, suppose an engine is employed in hoisting, and that the load demands the exertion of its full power to accomplish the work; in this case the governor will never stop the intermittent motion of the valve-gear, and explosions will take place as rapidly as possible—say 30 per minute—while the load is being raised. Now, suppose that the load gets to the top, and the work is suddenly thrown off, the effect of this will be to increase the speed of the engine sufficiently to cause the governor to stop the pawl; and until the governor descends again by the speed dropping, the engine will not make another stroke or explosion. In some of the best of these engines there will be a pause of a minute before this takes place; or in other words, only l/30th of the power of the engine is required to move itself whilst doing no work.

The igniting of the gases is performed by the slide-valve and two lighting jets, burning one before the other, in the valve itself, in the excavation if. By the motion of the valve the space d2 first goes down and ignites its contents (gas and air), at the flame burning continually before the valve, then comes up to X, where it ignites the charge.

It may be interesting to mention that this gas-engine may be considered as a new form of steam-engine, inasmuch as the chief result of gas combustion is nothing but steam expanding from 2000° Fahr. down to 150° Fahr. The high pressure giving the upward motion to the piston is not lost, but the speed of the piston makes it fly much higher (see left-and diagram, Fig. 4) than the atmospheric line, and, by forming a partial vacuum, the decrease of temperature condenses the steam.

The right-hand diagram was taken from a horizontal gas engine acting by direct force of explosion. Nearly half of the out-stroke is occupied in drawing in the charge, the return stroke being an open exhaust.

The Langen & Otto engine has the demerit of being noisy, and of requiring a very large cylinder. It has this great merit, that the governor may stop the motion of all the parts except the fly-wheel and shaft. It starts with full power at a moment's notice: uses no fuel when not running, and but little when exerting only power enough to effect the regular rotation of the fly-wheel; requires but trifling attendance; gives no trouble with coal or ashes; requires very little water; is free from danger, and does not affect insurance's.

The consumption of gas, indicated by Professor Tresca, on an engine of 0.86 H. P. was 40.1 cubic feet per hour per indicated H. P., including 2 cubic feet by the lighting-jets. At present, the consumption of gas is slated to be but 26.5 cubic feet per H. P. per hour. The cost in Philadelphia would, for this consumption, 5.7 cents per H. P. per hour. A small steam-engine, requiring 18 lbs. of coal per H. P. per hour would cost about 6 cents for the same power, if run continuously.

Using pure hydrogen, two-fifths the theoretical efficiency of the fuel might be realized on the brake. With 1 volume of coal-gas and 6½ of air, a consumption of 1.05 cubic feet of gas per minute should give, theoretically, 584,000 foot lbs., of which the brake shows 12 per cent. The very best steam engine, consuming 2 lbs. of coal per H. P. per hour, uses 23,505,856 theoretical foot lbs., and gives out but 1,980,000 foot lbs., or only 8½ per cent. The patentees' agents in America are the Messrs. Schleicher Bros., 119 South Fourth street, Philadelphia.—Polytechnic Review.

German Patent #1,500. |

|

1876 Otto Gas Engine Works, Langen & Otto Gas Motor

1876 Otto Gas Engine Works, Langen & Otto Gas Motor

1876 Otto Gas Engine Works, Langen & Otto Gas Motor (Sectional View of Base)

1876 Otto Gas Engine Works, Langen & Otto Gas Motor (Sectional View of Base)

1876 Otto Gas Engine Works, Langen & Otto Gas Motor (Sectiol view of Friction Clutch)

1876 Otto Gas Engine Works, Langen & Otto Gas Motor (Sectiol view of Friction Clutch)

|

|