|

Title: |

1904 Article-William Powell Co., Class A Lubricators |

|

Source: |

Friction & Lubrication, 1904, pgs. 91-96 |

|

Insert Date: |

3/11/2025 10:51:58 PM |

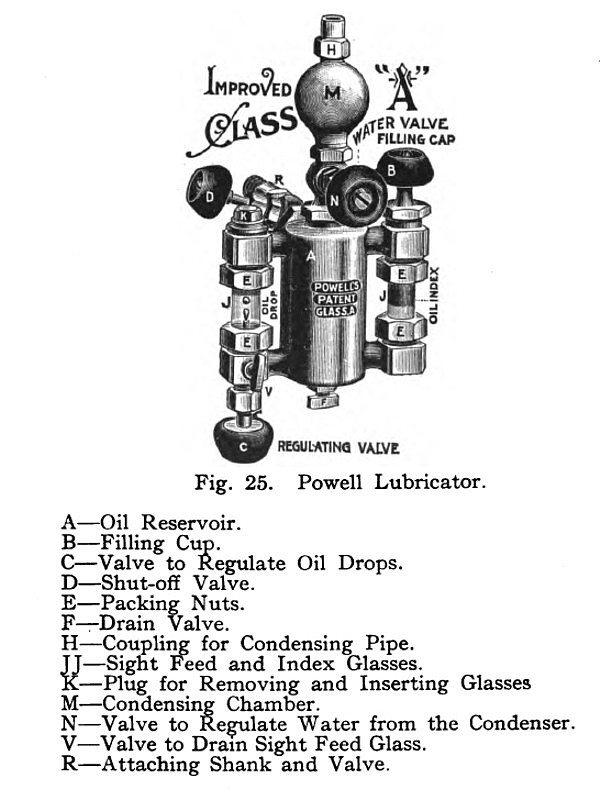

POWELL LUBRICATORS.

One of the best and most extensively used lubricators is the "Class A" up-feed lubricator, manufactured by the Wm. Powell Co.; it is made in sizes from one-third of a pint to one gallon, and made to stand heavy pressures.

Figure 25 shows an external view of the "Class A" lubricator, and the letters designating its different parts.

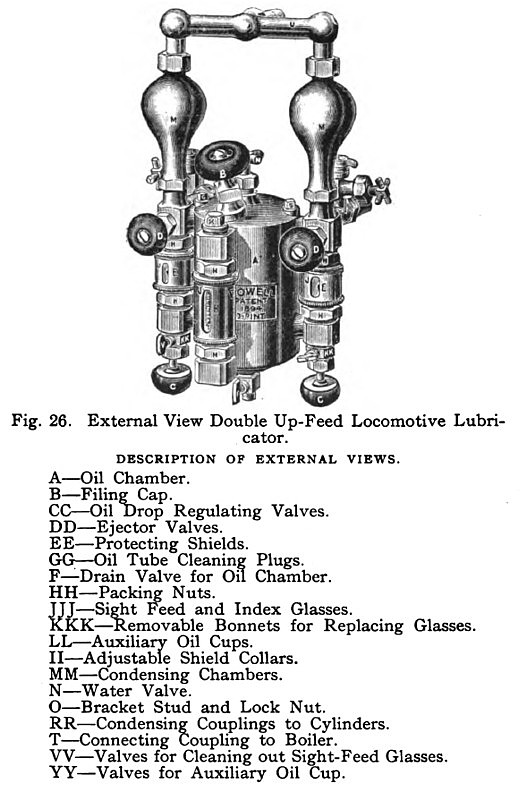

This lubricator is for use on single cylinder engines, but for locomotives, compound and triple expansion stationary and marine engines this firm makes a double or triple feed lubricator, which is preferable to the single feed, as two or three sight feeds are combined with one oil chamber.

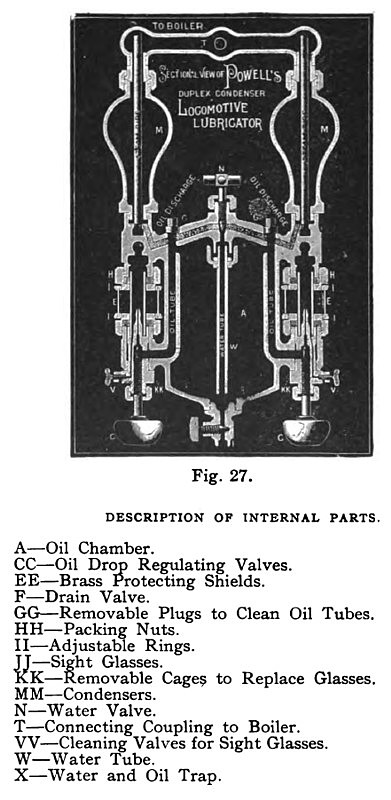

Figures 26 and 27 show external and internal views of the Powell Duplex Condenser and Double up-feed Locomotive Lubricator. The operation of this type of lubricator can be readily understood by a study of the sectional views.

One of the features peculiar to this lubricator is the provision made to prevent "cross feeding" and "siphoning" of oil, which is liable to occur on locomotives when going down grade with the steam shut off from the cylinder. "Cross-feeding" is provided against by having a separate and independent condensing chamber and steam pipe to each oil delivery pipe; the connection between the two cylinders is entirely cut off and each sight feed acts independently of the other.

"Siphoning" is prevented by means of the oil and water trap which is connected to the top of the water tube (W) and insures an adequate and positive supply of water to the lubricator after it is filled with oil.

After adjusting the feed valves (C C) to the desired number of drops per minute they need not thereafter be disturbed, as the closing or opening of the ejector valves (D D) or the water valve (N) will at once stop or start the lubricator to feeding; this is a convenience that all engineers will appreciate.

Another valuable feature of this make of lubricator is the auxiliary cups (L). By means of these an extra supply of oil can be fed to the cylinders without disturbing the feed valves (C C). By pouring oil into the auxiliary cups and opening the valves (Y Y) the oil can be instantly blown by live steam to the steam chests and cylinders. When the auxiliary feed is not in use valves (Y Y) should be kept closed.

These lubricators are very simple in their operation. To refill and start close the valves (D D) or (N) and draw off the water through the drain (F), then close (F) and fill the oil chamber through the filling plug (B), close (B) and open valves (D D) or (N) and the oil will commence feeding through the sight feeds according to the rate at which it has been set.

US Patent: 534,006

https://www.datamp.org/patents/displayPatent.php?number=534006&typeCode=0 |

|

1904 William Powell Co., Class A Lubricator

1904 William Powell Co., Class A Lubricator

1904 William Powell Co., Locomotive Lubricator

1904 William Powell Co., Locomotive Lubricator

1904 William Powell Co., Locomotive Lubricator (Sectional View)

1904 William Powell Co., Locomotive Lubricator (Sectional View)

|

|