|

Title: |

1853 Article-Isaac Brown, Steam Saw Mill |

|

Source: |

Scientific American, V 8 #49, 20 Aug 1853, pg. 388 |

|

Insert Date: |

11/11/2014 1:34:55 PM |

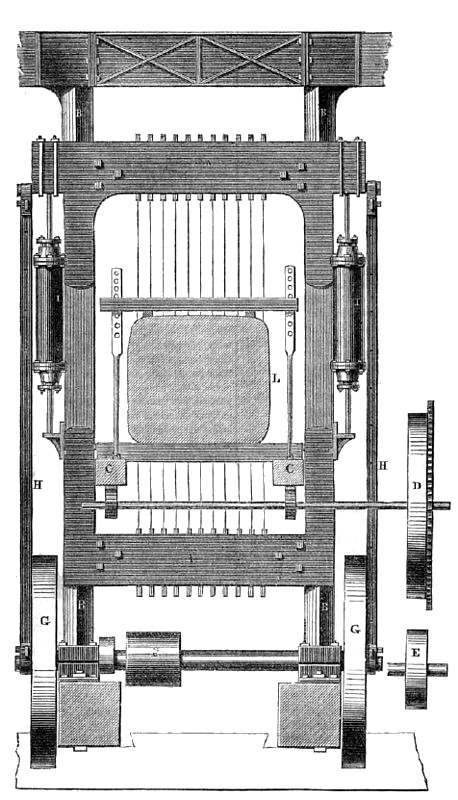

The annexed engraving is a view of an improvement in saw mills, invented by Isaac Brown, of Baltimore, Md., for which a patent was granted on the 19th of last month. The improvement relates to gang saws.

The engraving represents a front view of the saw gate, with a log passing through the mill.

A A is the saw gate; B B are the fender posts; C is the carriage with a log, L, on it, which is being carried through the mill and sawed into planks by the gang of saws in the frame; D is a rag wheel and backing pulley, E being the pulley to back the carriage; G G are fly wheels with pins set eccentric, forming cranks; they are attached to the connecting rods, H H; II are steam cylinders firmly secured to the fender posts in such a position that the centre of the piston rod is in line with the centre of the cross section of the saw cross head. The saw gate is made in the usual way, except the top cross girt, which is projected over the sides sufficient to let the piston rod press against it in its upward motion. The piston rod is secured to the cross girt by adjustable stirrups, and the connecting rod pin projects over the cross girt, so as to allow the said rod, which is attached to the fly wheel, G, to work clear of the cylinder.— There is also a piston rod extending through the bottom of each cylinder, which is attached to a bracket on the side of the saw frame, to press in the downward motion of the piston on the bracket, and give motion to the saw frame. Owing to this mode of connecting the piston rods with the saw frame, the vibrations of the latter are not communicated to the piston to make it wear out of line in the cylinder. The claim of the patent is for this mode of preventing the vibrations of the saw frame wearing the piston untrue and out of line. The shaft for the fly wheels is firmly secured at the bottom of the frame, and runs in suitable boxes. The fender posts are constructed in such a manner as to form guide slides for the saw frame. It is best to make the saw gate of wood and boiler iron combined, the iron being so cut as to project up and down upon each side piece, making a cross frame side to side, all riveted securely together,—allowing an opening in the bottom and top girts to hang the saws in, and made of a strength according to the number of saws to be employed. Each cylinder has a stuffing box on each end, and the piston rod is guided so as to work truly through the cylinder.

The carriage, or feed rollers to forward, the timber to the saws for feed and back motion, may be applied with equal advantage according to the kind of lumber to be sawed. For flooring boards, or white pine boards, using circular saws for edging, the feed rollers will be the most expeditious mode of manufacturing lumber. For ship plank, and bill timber, the carriage may be considered the best, either with constant feed or rag wheel. Six inch steam cylinders of twenty feet stroke will be sufficient to work a gang of fifteen saws for sawing ship planks. Eight inch cylinders of twenty-four inch stroke, will drive from 30 to 40 saws, cutting flooring inch boards edged by circular saws. The fly wheels are about 4 feet diameter, and weigh 1,000 lbs. each. Their faces are turned to receive a belt to work the shaft of edging saws. One steam cylinder of 6 inch bore, and two feet stroke will drive a saw hung on each side of it; a separate carriage being provided for each, two logs may be fed into the saws at the same time.

These mills are very portable, they can be put up in a short time, and Mr. Brown informs, us they can be furnished at half the cost of other mills, which will do the same amount of work. They require less hands to operate them, and with a steam boiler and the frame and appendages as represented in the above engraving, there is at once a handy and convenient steam saw mill. Orders for these mills are filled by Messrs. Stillman, Allen & Co., of the Novelty Works, this city, and more information may be obtained by letter addressed to Mr. Brown, No. 80 South Exeter Street, Baltimore.

US Patent: 9,855 |

|

1853 Isaac Brown, Steam Saw Mill

1853 Isaac Brown, Steam Saw Mill

|

|