|

Title: |

1849 Article-Roys & Wilcox , Machine for Making Tumbler Stove Pipe |

|

Source: |

Scientific American, V 4 #51, 08 Sept 1849, pg. 401 |

|

Insert Date: |

11/6/2014 9:27:52 PM |

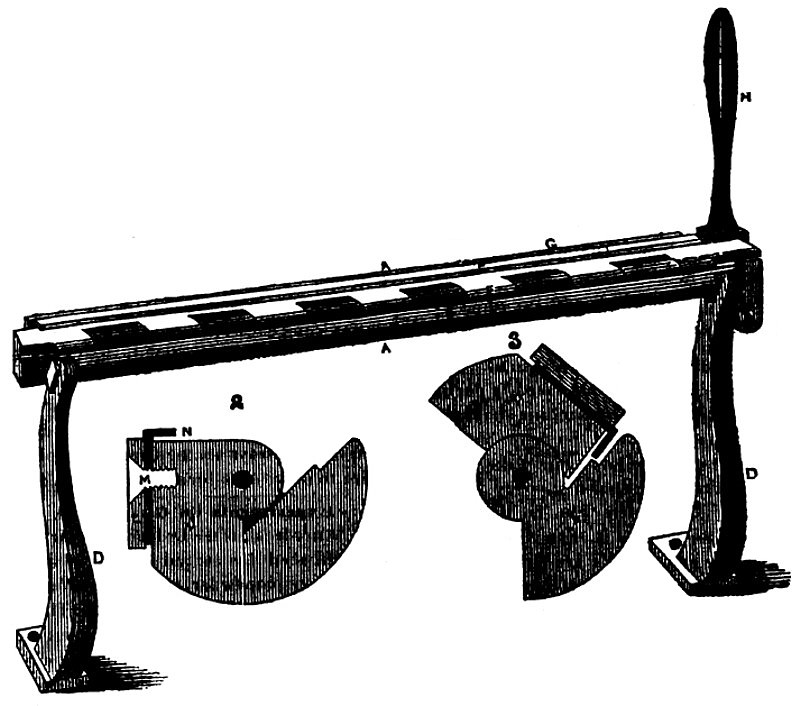

MACHINE FOR MAKING- TUMBLER STOVE PIPE.

This is a very useful and ingenious machine, invented by Mr. J. J. Wright, of Rochester, N. Y., and patented in the month of March last. These machines are now manufactures by that excellent company, Roys & Wilcox, of the Matabessett Works, Berlin, Conn., where all orders are promptly supplied with the best materials. They will no doubt soon have an extensive sale for this valuable machine, which should he in every tinsmith’s shop.

Fig l is a perspective view, showing the machine open and ready for use Figures 2 and 3 are transverse sections, showing the inside parts. D D are the legs fastened to the bench in any known way. E is a tumbler; it is fastened to the bed piece, C, and forms a hinge—the tumbler, E, working on the said hinge, while the bed piece, C, is stationary ; F is a folding slide; it is connected to the lever, H, by means of a pin, which works in a slot cut in the side of the said lever next to the tumbler. G is the top edge of a cap plate, which is fastened to the tumbler, E, by screws, which pass through the folding slide, F. In this slide there is a slot which works on the screws. By moving the lever, H, in the direction of A, the folding slide, F, is brought down into the tumbler, E, and by moving the lever back, the slide is raised, as now represented. In order to turn a lock on a sheet of metal of any kind, the edge of the sheet is pushed in between the tumbler, E, and the folding slide, B. The lever, H, is then moved in the direction spoken of, which brings the folding slide down on to the edge of the sheet, and holds it fast then by drawing the lever forward and down, the folding slide is brought over so as to come into contact with the bed piece, C, and the lock is then turned. By throwing the lever back, the sheet with the lock formed on it is taken out, and so on.

In fig 2, I is a section of the bed plate ; I, that of the tumbler; K the folding slide and the cap plate; M, one of the screws which pass through the cap plate and the folding slide in the tumbler, J; the sheet of iron is placed between the tumbler, I, and the folding slide, K at N. The tumbler, J. is then brought over, so that the folding slide comes in contact with the bed piece, I, as represented in fig. 3. Fig. 3 is a transverse section through the machine, when the cap plate is in its place. V is the bed piece section; W, the tumbler; X, the cap plate ; Y, the pin on which the tumbler works; Z is the folding slide.

One great advantage in this machine is, that after the pipe has been formed by rollers, the lock can be turned completely ready for use. In the common way of making stove pipe the lock is turned on the edge of the sheet of iron when the sheet is flat, hence a great difficulty arises in forming the pipe by rollers, or otherwise, without injuring the lock, for the rollers will not work truly up to within about half an inch, or more, from the lock, and for this reason the operator has to finish the pipe with a mallet, on a stake, after the pipe is put together. This difficulty is completely obviated by this excellent invention, because the pipe is formed with rollers before the lock is turned.

US Patent: 6,216 |

|

1849 Roys & Wilcox , Machine for Making Tumbler Stove Pipe

1849 Roys & Wilcox , Machine for Making Tumbler Stove Pipe

|

|