|

Title: |

1849 Article-Joseph Adams & Son, Felloe Machine |

|

Source: |

Scientific American, V 4 #22, 17 Feb 1849, pg. 169 |

|

Insert Date: |

11/3/2014 10:44:26 PM |

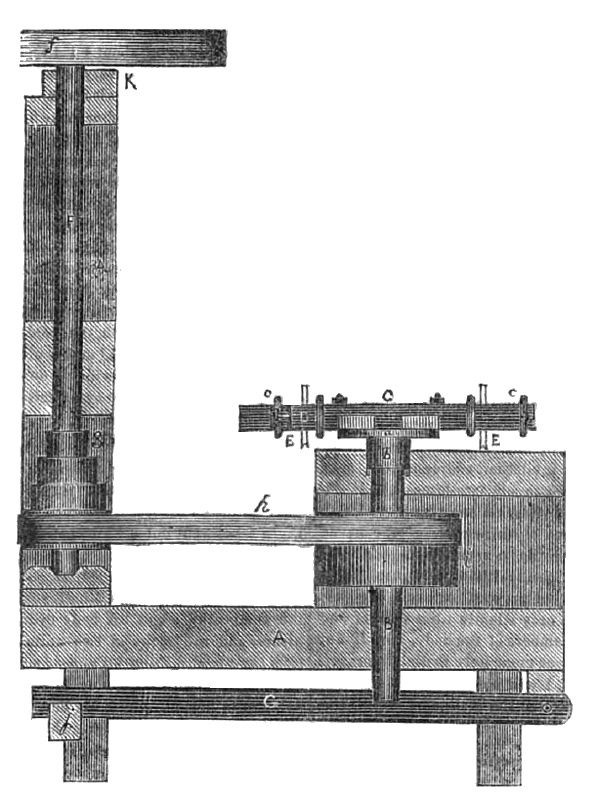

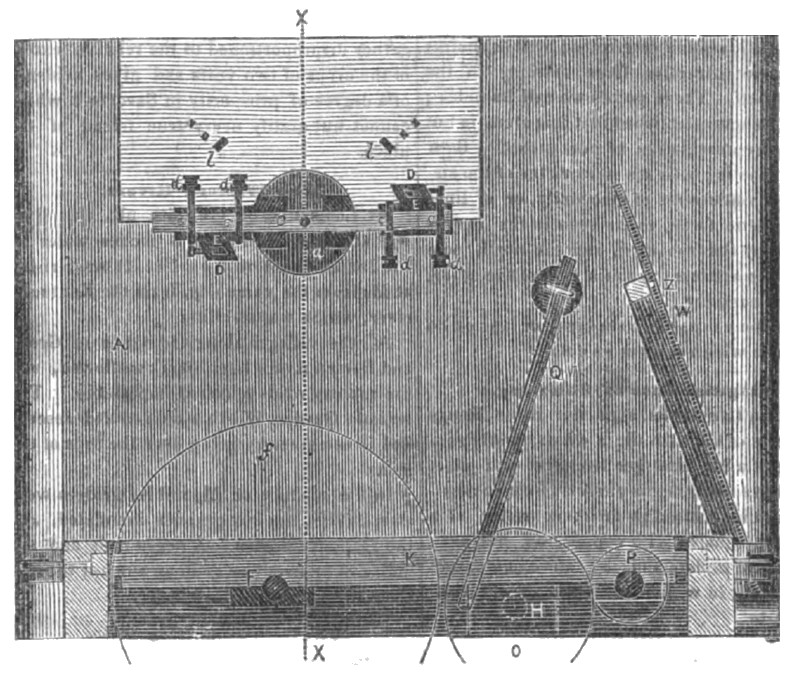

This is a machine for cutting felloes of wheels out of plank, on which valuable improvements have been made by Joshua & Levi Adams, and T. H. Mores of Amherst, Mass., who have taken measures to secure a patent for the same. Fig. 1. is an elevated section of the machine at the line X X of fig. 2, which is a horizontal view, with the friction wheels removed. The same letters refer to like parts on both the figures.

A is a frame, B is an upright shaft resting in a moveable step at its lower end and having a circular plate a, secured to its upper end, above the hub b. C is a horizontal beam secured between projections on the upper surface of the circular plate. D are angular metallic boxes with flanges on their sides attached to the beam by the straps d. E, are the cutters of the desired form passing through openings in the boxes and adjusted by screws. F, is an upright shall resting in a step in the frame and turning in a box screwed to a vibrating timber at its upper end and with a friction wheel and pulley f at the top, and a gang of pulleys g below, around which is seen the band In extending around a pulley i on B. G is a lever arranged below the frame and secured at one end to the front of the same by a pin upon which it moves and at its opposite end upon a similar lever j, which is connected to a cross head, moving between upright ways. H is a vertical crew shaft passing through a screw in the cross head and having a button or shoulder at its lower end, which shoulder turns in a permanent block in the frame. Q, is a lever moving on a fulcrum and connected at the end by a rod, which is connected to a lever below the frame having a weight hung on its upper end to counterbalance the weight of the vertical shaft of cutters and levers to relieve the screws of part of the pressure and prevent it from wearing. K fig. 2 is a horizontal beam containing the boxes in which the upper ends of the upright boxes turn and it is provided with tennons at the ends which fit into mortices in the vertical parts of the frame and has cords attached to its ends one of which with a weight passes over a pulley in the outside and the other cord passes over another pulley and is attached to a lever Z W, moving on a fulcrum, for lowering the cross head by lowering the said lever.

When it is desired to cut a felloe, the plank from which it is to be cut is placed upon the tables and firmly secured by the dogs and clamps I. The upright shaft is then set in motion by the friction wheels being brought in contact by the lever and therefore the cutter shaft by the band h is set in motion. The cutters E E, are set in the cutter heads by the straps d d, so that one cutter shall move in a circle cutting the outside of the felloe and the other cuts the inside circle, while the cutter i shaft can be raised or lowered by the lever G, L to cut the required depth. The dogs and clamps can be shifted on the table for larger or 1 smaller felloes, and the cutters can be shifted on C C C, to correspond with the same.

By the end view, any person will get a good idea of the construction of this machine, but there are some little nice arrangements not herein exhibited, but the general arrangement is. We cannot say more in favor of this machine, than to state, that the felloes formed by it sell at a higher price than any other in our city.

US Patent: 6,521 |

|

1849 Joseph Adams & Son, Felloe Machine (Sectional View at XX)

1849 Joseph Adams & Son, Felloe Machine (Sectional View at XX)

1849 Joseph Adams & Son, Felloe Machine

1849 Joseph Adams & Son, Felloe Machine

|

|