|

Title: |

1912 Article-Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine |

|

Source: |

Machinery Magazine, V 18, Feb 1912, pg. 475 |

|

Insert Date: |

12/17/2019 4:19:05 PM |

THE SPIRO STEAM TURBINE

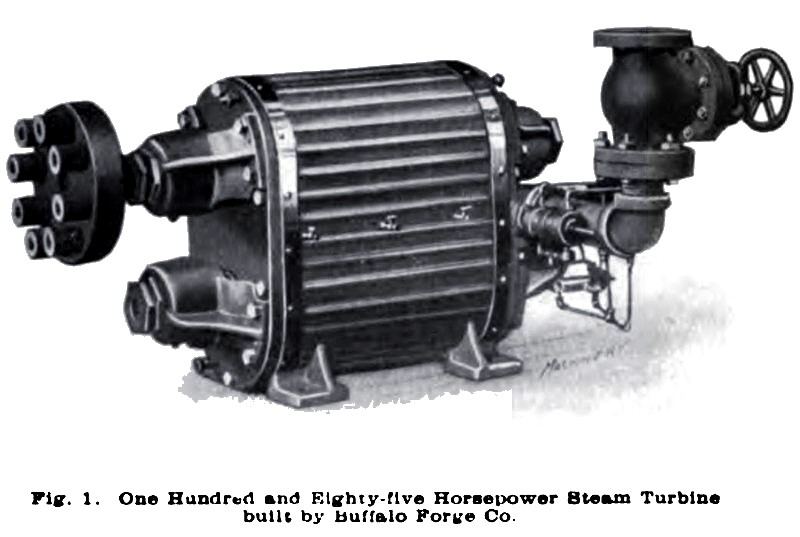

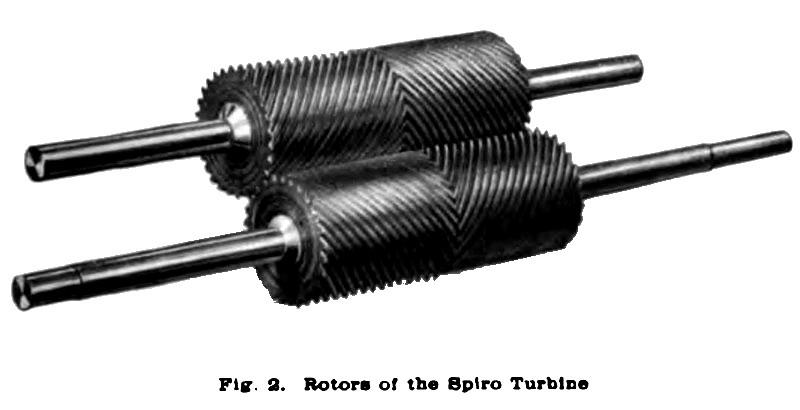

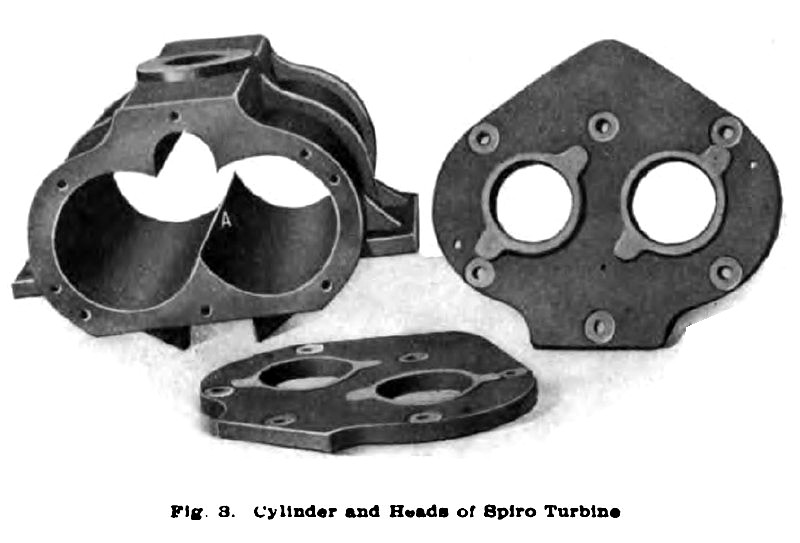

A new type of steam turbine, which is unique because of its simple construction and efficient as a prime mover, has been developed by Mr. John H. Van Deventer, superintendent of the Buffalo Forge Co., Buffalo, N. Y. One of the striking features of this turbine is its small size, considering the power developed. Fig. 1 shows a 185 horsepower unit, which has been used for the last three years for driving tans, gas scrubbers and other apparatus. We are informed by the builders that this turbine has not been apart or had a single adjustment made since its installation. The power of this turbine, namely 185 horsepower, was developed with 100 pounds initial pressure which is the standard by which all the turbines built by this company will be rated. This type of turbine consists principally of two rotors in the form of herringbone gears which are contained in a cylinder having suitable heads and bearings. The rotors are shown in detail in Fig. 2 and the cylinder and cylinder heads in Fig. 3. When the turbine is in operation, the steam is admitted to the central pocket formed by the right- and left-hand spiral teeth of each rotor, from a double port located at A in the center of the V-shaped rib which extends across the cylinder. The rotors, which are accurately fitted and mounted with relation to the cylinder bore, revolve outward from this central steam port. When any given tooth space has passed this port, the steam is automatically cut off, after which it expands in the spiral groove as the rotor continues to revolve, until the end of the groove is reached. As the apexes formed by the spiral grooves come opposite the exhaust port on the upper side of the cylinder (in this particular case), the steam exhausts into the atmosphere. The expansion of the steam takes places at a high velocity owing to the angularity of the rotor teeth and the peripheral speed, and as the steam enters every groove in the circumference of each rotor during a revolution, there are a great many expansions per minute. It will be seen that the length of the port determines the point of cut-off and, consequently, the ratio of expansion, so that any predetermined ratio can be obtained by changing the port construction. The size of this port could also be automatically varied by a. governor, though the turbine illustrated in Fig. 1 is not so equipped.

The action of the “Spiro” turbine is said to be practically noiseless, the only sound being a slight hum similar to that of an electric motor. There is also very little vibration, and foundation bolts are not necessary for direct-connected units. The teeth of the rotors are accurately cut and metal-to-metal contact is said to be prevented by a film of steam which cushions the teeth. The length of these rotors is much greater than would be necessary for spiral gears transmitting equal loads at equal speeds and, consequently, the maximum tooth pressure per square inch is limited to five pounds, which is much less than would be applied to gears for transmitting power. The lubricating system of the bearings is so designed that each bearing acts as an individual oil pump. circulating oil through the bearing between the shaft and bushing with positive pressure. This forms an oil film, which is automatically maintained as long as there is any oil in the reservoir, which forms a part of each bearing.

Tests made on turbines of this type show the following results: (2) Horsepower, 151; boiler pressure, 130 pounds; initial pressure, 115 pounds; speed, 2710 revolutions per minute: water per brake horsepower, 31.8 pounds (non-condensing). These turbines are at present manufactured in sizes ranging from 1 to 50 horsepower, non-condensing, and capacities up to 300 horsepower are in process of manufacture.

1,026,887

http://datamp.org/patents/displayPatent.php?number=1026887&typeCode=0

1,046,687

http://www.datamp.org/patents/displayPatent.php?number=1046687&typeCode=0

1,070,086

http://datamp.org/patents/displayPatent.php?number=1070086&typeCode=0

1,070,087

http://datamp.org/patents/displayPatent.php?number=1070087&typeCode=0

1,070,088

http://datamp.org/patents/displayPatent.php?number=1070088&typeCode=0 |

|

1912 Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine

1912 Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine

1912 Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine Rotors

1912 Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine Rotors

1912 Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine Cylinder & Heads

1912 Buffalo Forge Co., 185 H. P. Spiro Rotary Steam Turbine Cylinder & Heads

|

|