|

Title: |

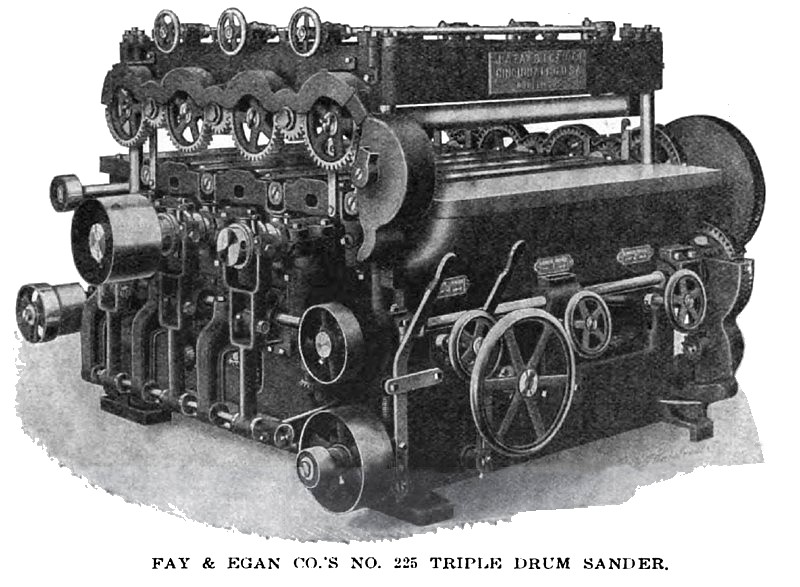

1911 Article-J. A. Fay & Egan Co., #225 Triple Drum Sander |

|

Source: |

St. Louis Lumberman, 15 May 1911, pg. 19 |

|

Insert Date: |

9/20/2014 7:28:49 PM |

An Improved Triple Drum Sander

The illustration herewith pertains to a new triple drum sander, called by its makers, the J. A. Fay & Egan Co., their No. 225. It is a machine with quite a number of exclusive features, and turns out work of a very high character, according to the testimony of its users.

It is a sander in three pieces, and in case of accident to the drums, or for recovering, it requires less than two minutes to elevate the entire upper works high enough to remove the drums, it necessary. The operator does not have to remove the bed plates or disturb the regular setting of the feed and pressure rolls.

Each size of the No. 225, it is claimed, weighs 3,000 lbs. more than the same size of any other make. It is consequently a very solid and well built machine all around.

The drums are made of hydraulic steel pipe. The shell being in one piece turned inside and outside,is perfectly balanced and non-breakable.

The paper is held absolutely tight on the drums by the manufacturer's automatic take-up device,which is suspended entirely on the shaft and does not depend upon spring pressures exerted against the shell of the drum.

The patented covering furnished with the manufacturer's drums is non-stretchable, firm enough to insure perfectly sharp edges and yet allow of a velvet finish.

Due to the qualities of the manufacturer's covering (the surface being absolutely true) the sanding paper is used evenly all over, thus making it last an unusually long time.

All the mechanism of the entire machine is exposed and easily accessible, saving an operator many hours a week by being able to watch and prevent cutting in the screws and nuts, thus preventing wear and insuring even pressure and good work.

New sandpaper can be placed on all three drums in from five to seven minutes.

With the manufacturer's oscillating mechanism it is practically impossible to produce the markings, generally termed “waves” and "planer marks."

All working adjustments are immediately in front of the operator and he does not have to leave his position to make such changes as are necessary.

The four corner screws are mounted on ball bearings, insuring easy movement for upper works and long life and quick adjustments.

The feed and pressure rolls are all made of seamless steel tubing, being non-breakable, and take a smoother finish than cast iron.

All bearings have reservoir self-oiling features.

For further particulars concerning this machine, those interested are invited by the manufacturers.

J. A. Fay & Egan Co., 224-244 W. Front St., Cincinnati, Ohio, to write for sander catalog. |

|

1911 J. A. Fay & Egan Co., Triple Drum Sander

1911 J. A. Fay & Egan Co., Triple Drum Sander

|

|