|

Title: |

1921 Article-Frontier Machine Tool Co., 20 in. Drill Press Type A |

|

Source: |

The American Machine and Tool Record, V24 #4, Oct 1921, pgs. 55-56 |

|

Insert Date: |

7/6/2014 1:55:23 PM |

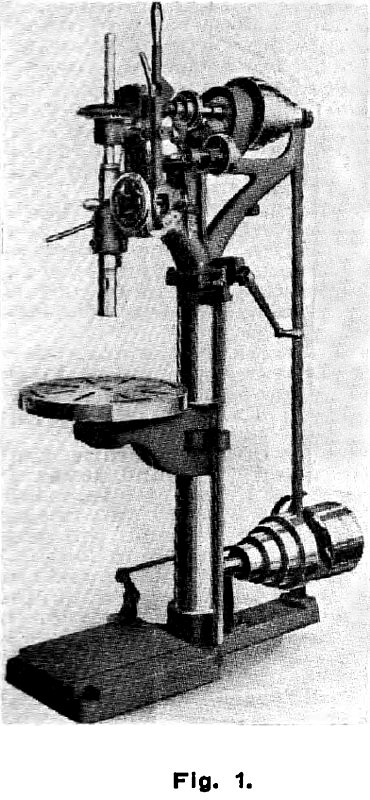

TYPE “A” FRONTIER 20-IN. SUPER DRILLING MACHINE.

Comparatively speaking, the present day output of drilling machines is practically unchanged in point of construction from those of a decade or two ago, only minor improvements having been added on the standard single column type of machines of this class.

It has come to be a commonly accepted belief that dead weight alone insures absolute accuracy. That this belief is fallacious is demonstrated by the fact that it is a very simple matter to move

a heavy object with a small pinch-bar and proper leverage. When it is remembered that the upward thrust produced from feed pressure embodies the same principle as the pinch-bar and fulcrum of what avail is dead weight in producing absolute accuracy.

It is an accredited fact that sufficient feed pressure can be employed by one man to produce an upward thrust that will completely offset the force of gravity; and to produce a bending stress on the main column that will cause a fluctuation in the degree of accuracy of noticeable proportions.

It is obvious that each additional application of a heavy feed pressure produces a corresponding bending stress on the main column. Constant use only serves to aggravate this defect and the accuracy of the machine becomes seriously impaired. Dead weight alone can never overcome this deficiency.

The purchaser of the present day single column type of 20-in. vertical drilling machine really buys a considerable quantity of unnecessary cast iron instead of drilling efficiency. It is obvious that the only way to remove all bending stress from the main column is to apply a force that will effectively counteract the upward thrust produced from heavy feed pressure.

This counteracting force must not be just sufficient to supply a temporary relief. as is the case where mere dead weight is used as a counter-agent, but must have a lasting effect equal to the life of the machine. Such a counteracting force has been applied to the Frontier super drill by the simple expedient of a back column. Fastened securely to the extreme ends of the frame and the extended base it supplies a counteraction that no amount of feed pressure can deflect.

Since with the application of the back column the Frontier super drill is equipped with a counteracting force which no amount of feed pressure can vary in the slightest degree it is obvious that the degree of accuracy at the spindle is correlatively incapable of variance. The bending stress caused by heavy feed pressure is entirely removed from the main column. The main column, therefore, function only as a support for the table and a partial support for the same.

When a counteracting force is employed which eliminates bending stress entirely, it is obvious that the life of the machine is prolonged to a considerable extent beyond that of a machine where no such counter-agent is employed. Where absolute accuracy is assured and practically impervious to the depreciative effect of constant use, worn parts can be replaced time and again and the drill becomes as good as new.

Consistent with the quality that predominates in the manufacture of the Frontier super drill, all bevel gears, except the large crown gear, all worms and pinion gears, are made of chrome steel instead of cast-iron, prolonging the life of the drill far beyond the normal.

One of the principal objectionable features of the average type of single column drilling machine is, that when the hand lever is thrown back violently and the power feed bevel gears fail to mesh, the bevel gear teeth, usually made of cast-iron, will chip and break, necessitating frequent replacement and usually rendering the machine useless until a new set of gears are obtained and installed.

This objectionable feature has been completely eliminated on the Frontier super drill, in which the power feed bevel is supported by means of a steel spring. Consequently when the hand lever is thrown back violently and the bevel gears fail to mesh, the force of the thrust is taken up by the spring. A slight turn of the hand wheel instantly re-engages the gears; it being impossible when throwing back the hand lever, to cause the slightest damage to the bevel gear teeth.

The power feed worm gear has 42 teeth. Thus power feed operation is effected instantly. This feature eliminates another annoying and costly objection: That of necessitating 200 or 300 revolutions of the pulleys before the power feed gears engage.

The wide range of work possible, using a drill scarcely larger than a. darning needle up to as large as 1% in. and the quick return lever at the left of the operator, the ease and efficiency with which all operations are performed are all features worthy of note in this Machine.

In the drilling machine illustrated, manufactured by the Frontier Machine Tool Co., 123 Lakeview avenue, Buffalo, reference is made to some important improvements in drill construction, for instance: The specifications of this machine are as follows: Swing, 20 ins.; drill capacity, 0 to 1½ ins.; travel on column, 24 ins.; travel on spindle, 8 ins.; distance between table and spindle, 26 ins.; distance between base and spindle, 38½ ins.; diameter of table, 17 ins.; diameter of spindle in sleeve, 15/16 ins.; diameter of crown gear, 5½ ins.; diameter of bevel pinion, 3 ins.; double column, 5? by 1½ ins.; diameter of 4-step cone pulleys, 21¼ ins.; diameter of tight and loose pulleys, 91¼, by 2? ins.; spindle socket, No. 3 Morse taper; thrust in spindles, ball bearing; speed, 300 r.p.m.; base, square with T-slots; bearings on upper shaft, split and long; height, 76 ins.; floor space. 15 by 48 ins.; net weight, 625 lbs. |

|

1921 Frontier Machine Tool Co., 20 in. Drill Press Type A

1921 Frontier Machine Tool Co., 20 in. Drill Press Type A

|

|