|

Title: |

1921 Article-Frontier Machine Tool Co., 20 in. Drill Press Arranged for Motor Drive |

|

Source: |

The American Machine and Tool Record, V24 #4, Oct 1921, pg. 62 |

|

Insert Date: |

7/6/2014 1:37:19 PM |

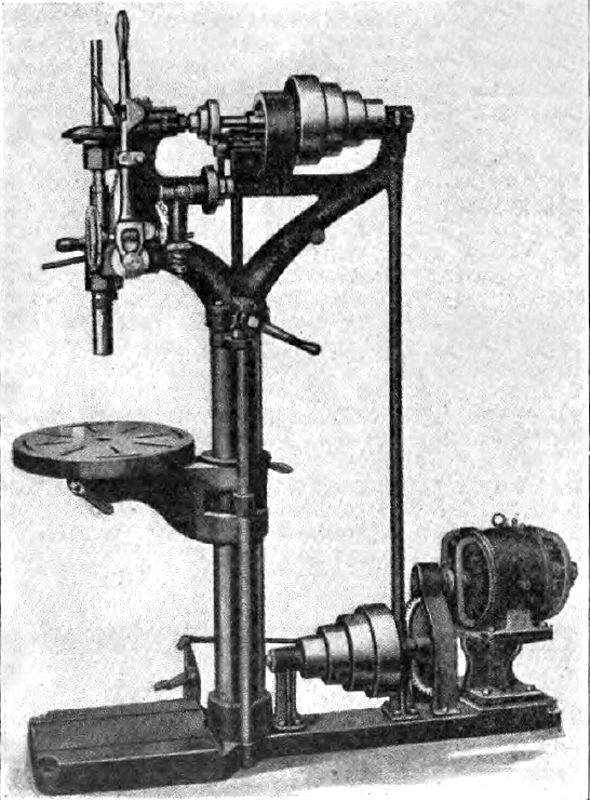

THE FRONTIER 20-IN. SUPER DRILL TYPE “A” ARRANGED FOR “MOTOR DRIVE.

Elsewhere in this issue is printed a description of the Frontier Type “A” 20-in. Super Drilling machine with belt drive. The builder, the Frontier Machine Tool Co., Inc., of 123 Lakeview avenue, Buffalo, is also building the same type of machine, but arranged for motor drive instead of belt.

Especial attention is called to the method of arranging the machine for the motor drive. The usual method employed on motor driven 20-in. drill presses is to support the motor on a bracket which is _attached to the frame of the main column. The objection to such an arrangement is of course obvious because the main column on a single column machine is not sufficiently rigid to adequately withstand the bending stress caused by the upward feed pressure when driven by a belt; it is, therefore, also apparent that if in addition to this objectionable feature, when a heavy motor is also attached making it necessary for the main column to support the added weight of such heavy motor, it only increases what heretofore has always been considered as a serious defect in drill press construction.

The builder of the “Frontier" in an effort to produce a drilling machine that would prove absolutely free from the objectionable feature referred to and to meet the present day requirements of a drilling machine, has designed this motor driven machine in such manner as to positively eliminate any additional strain on the main column when motor is attached.

It will be noted by reference to the illustration that the base of the Frontier Super-Drill is extended considerably beyond that of the present day type and that the motor is placed on a stand which rests on and is clamped to the floor. The drive is by means of gears and the motor is arranged so that the maximum of power is transmitted to the driving gears with a minimum of energy.

The result of this method of motor drive application is to cut down overhead by reducing transmission waste which is always present in any arrangement using a belt drive instead of a gear drive.

The machine itself is the standard Frontier Super-Drill and the method used in arranging the motor drive is such as to permit any user of a Frontier type drilling machine operating with a belt drive to change over to the motor drive at very little expense incurred for material and labor. |

|

1921 Frontier Machine Tool Co., 20 in. Drill Press Arranged for Motor Drive

1921 Frontier Machine Tool Co., 20 in. Drill Press Arranged for Motor Drive

|

|