|

Title: |

1867 Article-Philip S. Justice, Power Hammer |

|

Source: |

American Artisan, 10 Jul 1867, pg. 8 |

|

Insert Date: |

6/25/2014 7:20:18 PM |

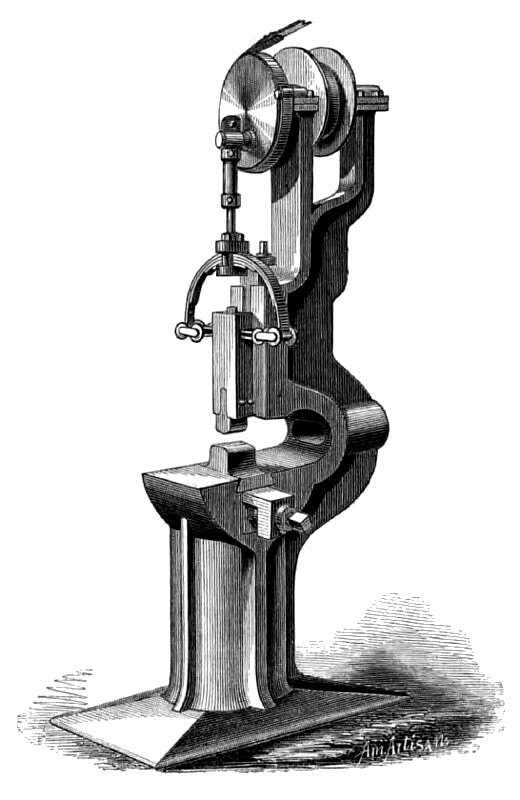

Shaw & Justice's Patent Power Hammer

This hammer is especially intended to take the place of the old-fashioned and cumbersome trip-hammers, which the inventors call “vexatious and unprofitable machine for their purpose." Necessity compelling them to adopt a substitute, they were led to the invention of the hammer represented in the engraving.

The hammer is driven by a slack belt, which is run from the line of shafting to the hammer-pulley and is made to bind by an idler or tightening pulley, which is pressed upon it by a lever. The power obtained is not due to the momentum of the ram merely, but the principal agent is the elastic force of a steel bow-spring attached to the ram the center of a connection, which braces the extreme points of the bow, the pitman which imparts the reciprocating motion being attached to the central portion of the bow and its opposite end secured to the stud upon the crank where the motion is communicated. This arrangement of the ram suspended from the steel bow-spring entirely prevents the destructive shock which usually follows a blow given by a steam or trip hammer upon a foundation in which there is no elastic material; all the upward reaction of the hammer following the blow being absorbed by the flexible belt upon which the ram is hung to the bow. It is found that with all the velocity given to the ram, no power can obtain from it other than that of an accelerated drop or dead fall.

An arrangement is also provided for the instantaneous stopping of the hammer, which consists of a leather belt encircling the main wheel and connected to the idler pulley-frame, so that when the hammer is to be started the brake is thrown out of gear with the wheel, and in gear when the hammer is to be stopped; the action of this is instantaneous, and without straining or racking the machinery.

The idler-pulley is easily worked by the foot of the man who runs off the “heat." The bottom die of the anvil block is held by means of a wedge-shaped gib, which is tightened by a screw. This prevents all possibility of bursting the block, as is often the case where keys are used, and has another advantage in the saving of time in adjusting the bottom die parallel with the hammer, a feature of great importance where dies are used.

The qualities claimed for this hammer are simplicity, durability, reliability, and economy. They are made of sizes with weight of rain varying from ten pounds to a thousand, and with a required power to run them from one quarter of a horse to ten horse. The size of the base of the smallest size is 26 inches in diameter and the largest five feet by six feet eight inches. They are adapted to work iron from less than five-eighths of an inch to nine inches, and will work steel equally as well as iron.

This hammer was patented by Thomas Shaw, of Philadelphia, Pa., on Feb. 27, 1866, and is also patented in some of the foreign countries. The hammers are manufactured by Philip S. Justice, who has offices at No. 14 North Fifth Street, Philadelphia, and No. 42 Cliff Street, New York City. |

|

1867 Philip S. Justice, Power Hammer

1867 Philip S. Justice, Power Hammer

|

|