|

Title: |

1859 Article-Benter, Burkle & Co., Stave Jointer |

|

Source: |

Scientific American, V 1 #24, 10 Dec 1859, pg. 377 |

|

Insert Date: |

5/27/2014 8:40:48 PM |

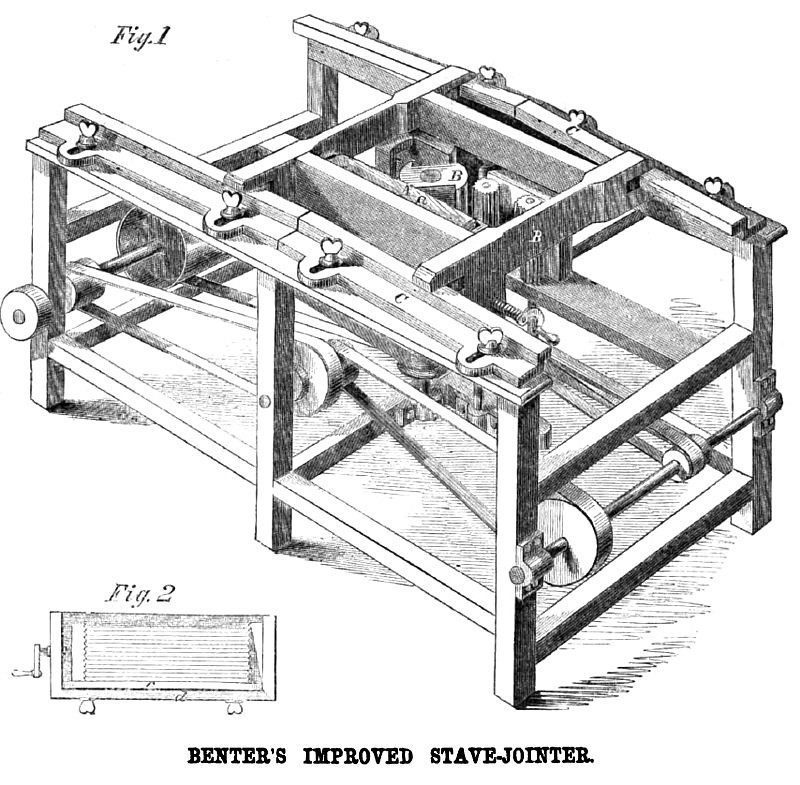

IMPROVED STAVE-JOINTER.

The accompanying cuts illustrate a very simple and efficient machine for jointing and dressing staves, for which a patent was issued through the Scientific American Patent Agency to Henry Benter, of Wheeling, Va., Feb. 22, 1859 (#23,007).

For jointing the edges of staves a pile, a, of staves is placed in the frame B, as shown, opposite the revolving cutter-head, b. The frame, B, slides in ways, C C, which are hinged in the middle, and are attached to the stationary frame of the machine by means of set screws passing through slots, so that the frame, C C, may be bent in the middle at any desired angle or placed straight, at the will of the operator. The object of this arrangement is to give the proper curve to the edges of the staves, by approaching them nearer to the cutter at each end than in the middle, as they are carried past it. Rollers with vertical axes are interposed between the edges of the ways and the sliding frame, B, both to reduce the friction and to obviate the effect of the angle in the ways on the motion of the staves, rounding them with a constant curve. To give the proper bevel to the edge of the staves, they are caused to rest in the frame with a slight inclination from a horizontal position. As it is necessary to vary this inclination for barrels of different sizes, provision is made for adjusting the angle with precision, by a device which is represented in Fig. 2. The staves rest upon a plate, c, which is hinged at the back edge, and which is supported at its front edge by set screws which pass through the firm lip, d, of the frame; turning these set screws, the angle of the plate, c, and consequently of the staves, is varied at pleasure. The

staves are held in the frame by a permanent serrated jaw at one end and a movable jaw at the other, which is moved by a screw and crank, as shown in Fig. 2. The frame, B, is moved back and forth, either by hand or by any usual automatic arrangement. For dressing the sides of a stave, it is clamped in the frame with its side to the cutter-head, which is furnished with cutters with convex edges for dressing the insides of the staves, and with cutters with concave edges for dressing the outsides. By introducing a second cutter-head, this operation of dressing the sides of the staves may be carried on at the same time with the jointing of the edges; the staves to be fed to the cutter by vertical toothed rollers.

For any further information m regard to this invention, inquiries may be addressed to Benter, Burkle & Co., Wheeling, Va., who manufacture the machines for sale: suitable for dressing common sized staves, $125; for heavy hogshead staves, $150; for very light staves, $75. |

|

1859 Benter, Burkle & Co., Stave Jointer

1859 Benter, Burkle & Co., Stave Jointer

|

|