|

Title: |

1859 Article-John Greenwood & Co., Machine for Resawing Barrel Heads |

|

Source: |

Scientific American, V 1 #20, 12 Nov 1859, pg. 328 |

|

Insert Date: |

5/27/2014 4:35:03 PM |

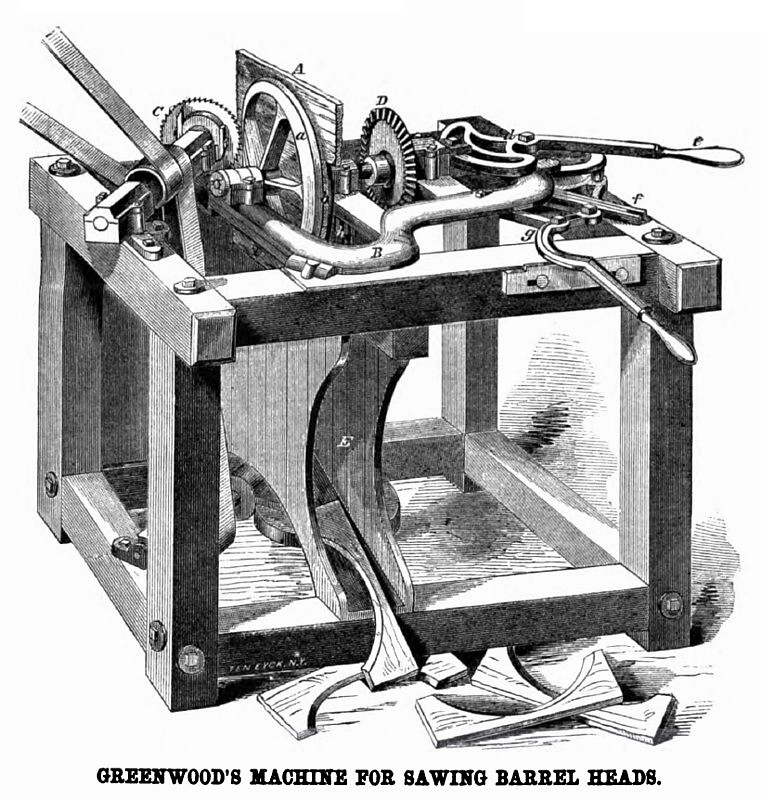

MACHINE FOR SAWING OUT BARREL HEADS.

The time seems to be rapidly approaching when all cutting of wood, whatever may be the form desired, will be done by steam or water power. This is the department of invention in which this country has taken the most decided lead, and, from the great number of new devices which we are continually called on to record, the approach towards perfection appears to be now more rapid than ever before. We illustrate at this time, a machine for sawing out barrel heads.

The "stuff," A, of which the 'barrel head is to be formed is held between two clamps, a and b, which have independent shafts in the same line. The clamp, 6, it secured firmly against the end of the shaft, c, the other end of which is connected by a gliding box and pin with the groove in the cam, d. Thus the clamp, b, may be drawn away by means of the lever, e, from its fellow, a, or pressed toward it, to release or confine the stuff, A, between the two. The frame, B, to which the several parts described above are attached, slides diagonally upon the principal frame of the machine in guides, one of which is shown at f. While the stuff is being secured between the clamps, the frame, B, is drawn back away from the circular saw, C; and after the stuff is secured, this frame is pushed along by means of the cam, g, so as to bring the stuff in contact with the circular saw. This motion throws the beveled wheel, D, into gear with the beveled pinion, A, which produces a slow revolution of the clamps, a and

4, carrying around the stuff in contact with the circular saw, which cuts it out in the form of a barrel head. The plane of the circular sow is placed at an angle with the plane of the clamps, and thus the saw forms one basil of the edge of the head, while the cutters, secured to the side of the saw, form the other basil; the edge coming directly into the angle, where the cutters meet the side of the saw. The concave pieces sawed from the head fall down the chute, E, and the head, when released from the clamps, falls down another chute on the other side of the machine. The circular saw is of course made dish-shaped, in order to cut stuff thus held diagonally with its plane.

The patent for this invention was issued (through the Scientific American Patent Agency) June 21, 1859 (#24,458), to John Greenwood, of Rochester, N. Y., who may be addressed at that place for further information in regard to it, or inquiries may be addressed to Daniel Bowker, New York City |

|

1859 John Greenwood & Co., Machine for Resawing Barrel Heads

1859 John Greenwood & Co., Machine for Resawing Barrel Heads

|

|