|

Title: |

1859 Article-Palmer & Co., Ward's Machine for Turning Irregular Forms |

|

Source: |

Scientific American, V 1 #3, 16 Jul 1859, pg. 33 |

|

Insert Date: |

5/24/2014 5:43:05 PM |

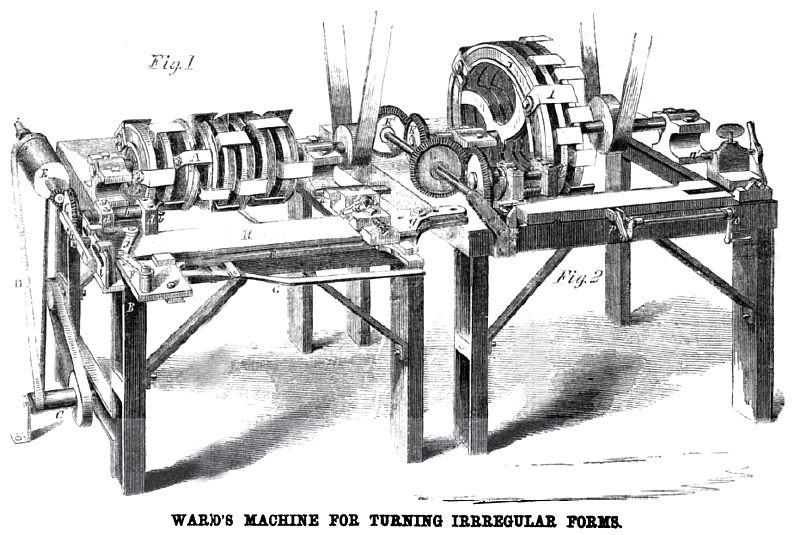

WARD'S MACHINE FOR TURNING IRREGULAR FORMS.

The mechanical contrivances which the busy thinking powers are continually producing are oft-times truly wonderful, and command admiration and attention from the most unlearned of their purpose and object, by the quickness and neatness with which they throw off their work

Our engraving represents two machines invented by Richard Ward, of Naugatuck, Conn., who is since deceased, and they are now extensively used throughout many parts of the country; and, judging from the working model which we have examined, they turn out spokes with great rapidity, and a finish which excels any hand-made spoke. The knives or cutters can be arranged to cut any form. The simple method of obtaining the requisite motion of the "stuff," to have the proper oval and taper, is ingenious in the extreme, and there are so few parts to perform such a great variety of work that it is not likely to get out of order or easily become damaged.

The first machine (Fig. 1) is for turning the oval of the spoke. A series of knives, A, are arranged lie between circular plates and placed on a shaft that runs across the frame, B. These knives are rapidly rotated by a belt from the shafting of the shop in which the machine is placed. The stuff is placed between the clamp, a and b; a being capable of being driven up to hold the stuff and then being locked by a cam, c, that tightens around the square shaft of a, and prevents it from sliding back; b is double, and its shaft is round, so that it is capable of rotating in bearings, d and it carries to receive the necessary motion a wheel, e, at its back. At the side of the machine is a drum, C, that can be rotated from any point that may be convenient; from this a belt, D, passes to a drum, E, on the frame, and the shaft of this carries a small bevel-wheel that rotates e on the shaft of E; there is also a loose pulley, f. The whole of these contrivances are placed on a plate, F, which slides on the main frame, and which can be moved back and forth to present the stuff to the knives or bring it back, by a lever that is pivoted at one end to B and connected by a link to F. The width of the drum, E, is so arranged that when the stuff is away from the knives the belt, D, is on the loose pulley, f, so that the stuff is not rotated; but the moment that the stuff is moved forward to the cutters, the band, D, moves forward on to E, and the stuff is rotated. To obtain the oval from the piece of wood that is to be formed into a spoke, it has to be moved back and forth before the knives while it is being rotated, and this is effected in a very ingenious manner. The supporters or bearings of the clamps, a and b, are placed on a plate, II, that is allowed to slide in an arc of a circle upon the plate, F, and it is centered by a pivot, g, which can be moved to give any taper to the oval that may be desired. The motion is given to this plate by a lever, A, pivoted to the wheel, e, so that it gives a reciprocating motion to a plate, i, that moves in guides on H, and by a system of levers, f, connected with and secured to F, it receives the proper motion to form the oval on the spoke.

When the oval portion of the spoke is formed, the cam, c, is released, and a driven back; the spoke is taken out and placed in the clamps, b', a', on the machine (Fig. 1), which cuts the hub-tenon on the spoke. The cutters, I, are arranged on a large cylinder, J, the shaft of which carries a bevel-wheel, K, that gears with a similar one, K', at right angles to it; and on the shaft of K', by means of a rebate, another bevel-wheel, L, is allowed to slide and give motion to the clamp, c, by the bevel-wheel on the back of its shaft, when connected by the connecting-gear that we will now describe. The bevel-wheel is loose on the shaft of c, and to the frame of the machine a small stud, m, is attached, which holds back the clutch by a lever, n; but when the clamp bed is moved forward by the handle, o, and crank, p, n is released from the stud, and a spring, g, forces the clutch into a slot or recess in the back of the bevel-wheel, and the stuff is rotated before the cutters to have the square tenon formed.

For any further information address Palmer & Co., box 4534, Post-office, New York. |

|

1859 Palmer & Co., Ward's Machine for Turning Irregular Forms

1859 Palmer & Co., Ward's Machine for Turning Irregular Forms

|

|