|

Title: |

1871 Article-Watts, Campbell & Co., Variable Cut-Off Steam Engine |

|

Source: |

Scientific American, V 24 #4, 21 Jan 1871, pg. 47 |

|

Insert Date: |

3/7/2014 8:59:47 PM |

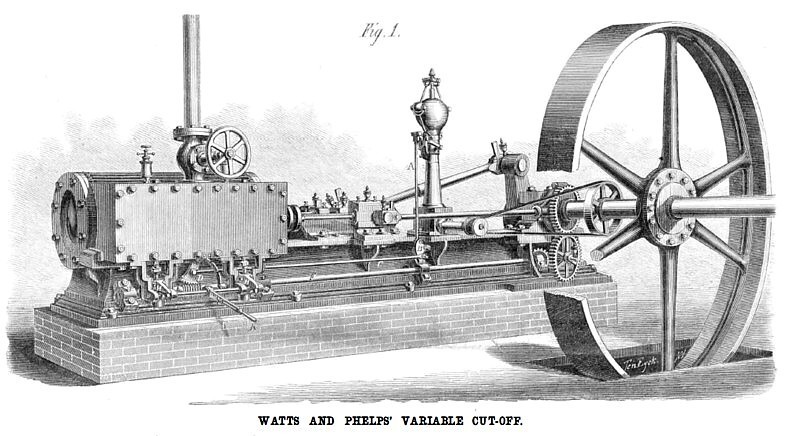

Watts and Phelps' Variable Cut-off Steam Engine

Our engineering readers will be interested in the engravings we herewith present of a new variable cut-off, invented by Wm. Watts and Fred. A. Phelps, of Newark, N. J.

The motions of this new valve gear are all positive, and the parts are all not only strong and durable, but easily adjusted to equalize the cut-off at each end of the cylinder. It has nothing about it, which seems likely to get out of order, and its operation (as shown by indicator diagrams taken from an engine, with this gear attached, by Mr. F. W. Bacon, whose engineering skill is familiar to many of our readers), gives economical results which justly rank as first-class, not-withstanding its freedom from the complications which, in many kinds of valve gear, necessitate constant attention and frequent repair.

The controlling power of the governor is transmitted through the connecting rod, A, Fig. 1, the sector, B, the connecting rod, C, and the toothed sector, D, to a cylindrical rack turned on the sleeve, E. The sleeve, E, is feathered to the shaft, F, and slides longitudinally when acted upon by the parts, A, B, C, and D, while turning with the shaft, F, the rotation of the latter being accomplished through a system of gearing, as shown.

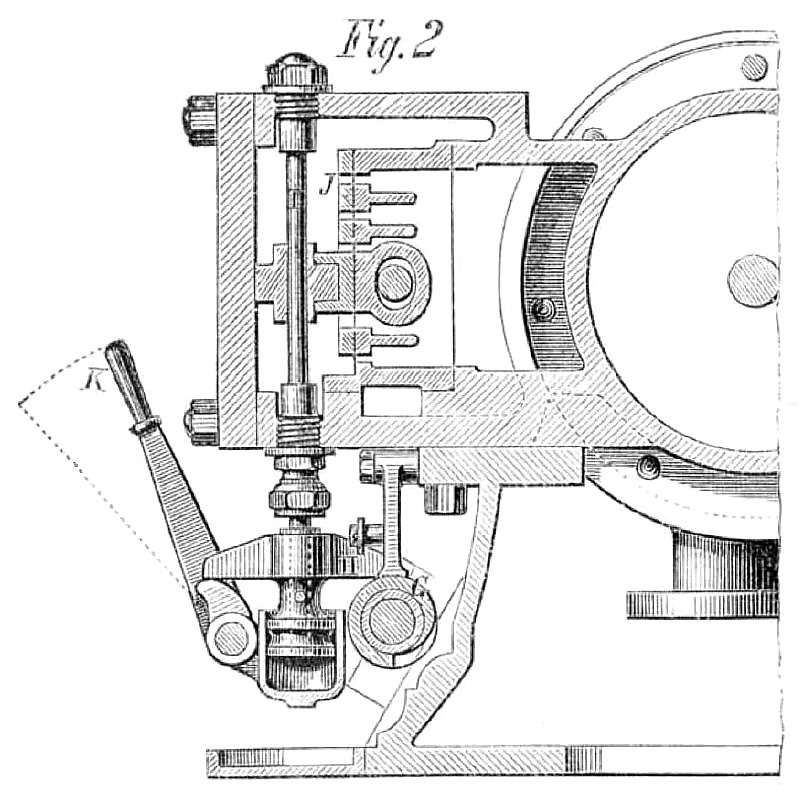

The sleeve, E, also carries two cams, shown in section in Fig. 2, at Q, which, turning under the toes of tappet arms, H, Figs. 1 and 2, attached to the vertical stems, I, Fig. 2, of the cut-off valves, J, Figs. 2 and 3,

raise the valves and let them fall abruptly at the proper point of cut-off to which they are adjusted.

The cut-off valves, J, are of the "grid" variety, and slide on the backs of the principal valves, which latter are actuated in the usual way from an eccentric on the crankshaft.

The sliding of the sleeve, E, on the shaft, F, causes the cams to let the cut-off valves fall earlier or later in the stroke, according as varying velocity affects the governor.

If the belt breaks or any other derangement of the governor occur, the travel of the sleeve, being a little more than the length of the cam, allows the toes of the tappet arms to drop off the cam on to the shaft, closing the cut-off valve ports and instantly stopping the engine. In starting the engine, a lever and cam, K, Figs. 1 and 2, is used to raise the cut-off valve and open the port. The motion of the engine then operating on the governor draws the sleeve along so as to bring the cams under the tappets, and thenceforward the gear works automatically.

It will be seen that this gear can be made to cut off from zero to any part of the stroke desired, and that it can be adapted to many kinds of engines in popular use, with but slight alteration.

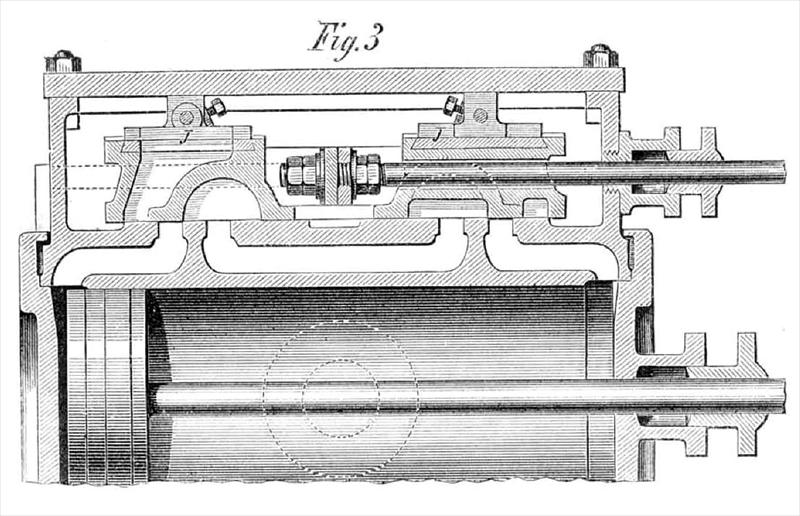

Fig. 3 is a horizontal section through the cylinder and valve chest which aids in showing the relations of the

parts.

As an illustration of the effectiveness of this valve gear we may say that with a double cylinder engine, having cylinders five feet by twenty-eight inches, running at forty seven revolutions per minute, in a large thread factory, in Newark, N. J., much difficulty was at first experienced on account of the variable power required to drive the machinery. The variations were so great that it was found impossible to govern the engine by the throttle-valve governor.

The application of the valve gear we have described, in connection with a medium-sized Porter's patent governor, has reduced this variation, so that, including the variation arising from inexactness in starting the engine at the precise moment for work to commence, and stopping at the end of each half day, its maximum irregularity does not exceed ten revolutions per day of ten and one half hours, as determined by a counter and attested by the engineer in charge.

The cut-off is extremely sharp, as shown by the diagrams, and the work required of the governor is very slight, it being only that required to overcome the friction of the connections, and to move the sleeve longitudinally on the shaft, F, as above described. As a consequence the action of the governor is delicate and sensitive to very slight variations in speed. These engines are manufactured by Watts, Campbell & Co., proprietors Passaic Machine Works, corner Passaic and Ogden streets, Newark, N. J., who may be addressed for rights or further information. |

|

1871 Watts, Campbell & Co., Variable Cut-Off Steam Engine

1871 Watts, Campbell & Co., Variable Cut-Off Steam Engine

1871 Watts, Campbell & Co., Variable Cut-Off Steam Engine (Cut-Off Valves)

1871 Watts, Campbell & Co., Variable Cut-Off Steam Engine (Cut-Off Valves)

1871 Watts, Campbell & Co., Variable Cut-Off Steam Engine (Valves & Piston)

1871 Watts, Campbell & Co., Variable Cut-Off Steam Engine (Valves & Piston)

|

|