|

Title: |

1899 Article-Greenwood & Batley, Ltd., Vertical Oil Engine |

|

Source: |

The Engineer Magazine, 23 Jun 1899 pg. 619 |

|

Insert Date: |

1/9/2014 9:27:26 PM |

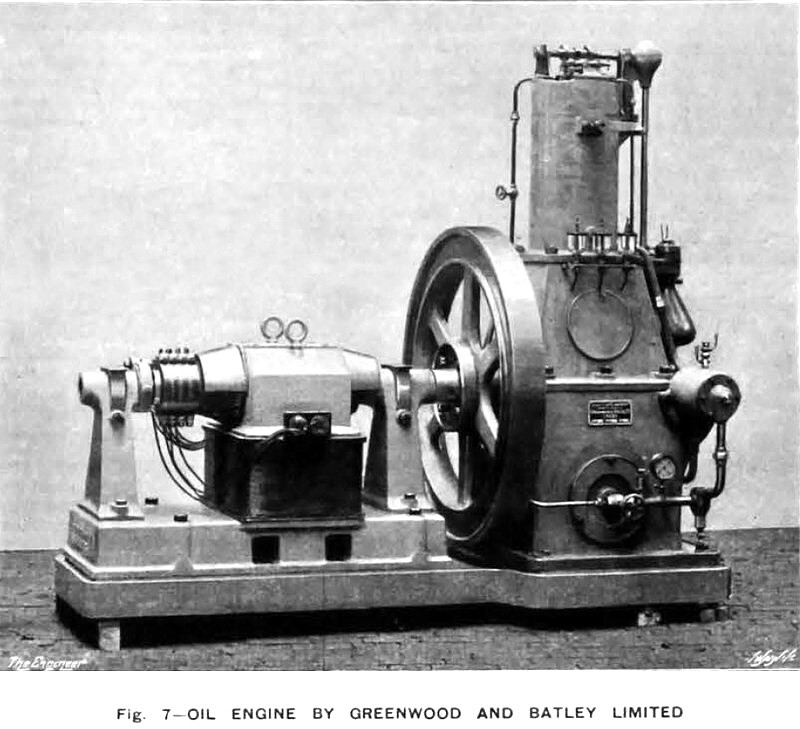

It is a vertical engine, and a general idea of its construction will he gathered from the engraving, Fig. 7, which represents an engine direct coupled to a dynamo. It works on the Otto cycle, and although the crank is entirely enclosed the crank chamber is not air-tight. At one side there is, a shown in the engraving, a pump driven by an eccentric on the shaft ; this supplies the air pressure for the oil feed. No vaporizer, in the usual sense of the word, is used. Inside the cylinder is a valve through which the oil is admitted; part of this oil burns with a flame which plays against a platinum coil, making it white hot. The major part of the oil is thrown by the air from the pump through the narrow annular space between two adjustable male and female cones against the heated platinum, and fired at the moment of maximum compression, thus giving the driving stroke.

Several automatic valves fitted in the piston itself supply the remaining air needed for combustion, in the usual way. The oil feed pump is peculiar; it can be seen just above the inverted pear-shaped casting, which encloses the centrifugal governors. On the top of the vertical governor shaft are keyed two small eccentrics. The lower one is of fixed throw; the upper one is variable by the governor. The lower works the valve the upper the oil pump; and, of course, the supply of oil and the

richness of the mixture vary with the position of the governor. The engine appears to work as steadily when light as when fully loaded. The accuracy with which it fires, even when the oil supply is very much reduced, is remarkable in view of the trouble generally found in this respect. Its success is probably due to the fact that the oil is fired rather In the form of a spray than a vapour, and consequently the presence of too large a volume of air, so fatal to the governing of many vaporizer engines, does not affect it The engine runs at a high speed, up to as much as 600 revolutions per minute, but 350 is the correct working rate. It is easily started. Near the top of the cylinder will be noticed a sight hole closed by a. lever. To start the engine, a. small mop saturated with petroleum, and lighted, is thrust through this hole, and held in such a position that it heats up the platinum coil to the necessary temperature for starting.

Courtesy of Grace's Guide:

http://www.gracesguide.co.uk/The_Engineer_1899/06/23 |

|

1899 Greenwood & Batley, Ltd., Vertical Oil Engine

1899 Greenwood & Batley, Ltd., Vertical Oil Engine

|

|