|

Title: |

1863 Article-E. B. Requa, Saw Mill |

|

Source: |

Scientific American, V 08 #15, 10 Oct 1863, pg. 225 |

|

Insert Date: |

12/5/2013 1:42:50 PM |

Improved Saw-mill.

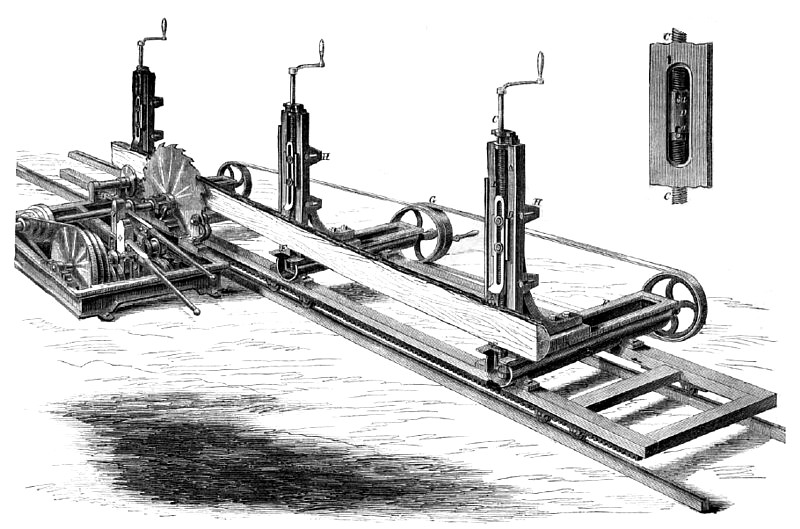

It is well known to lumbermen, mill owners, and sawyers, that much difficulty and loss is sometimes experienced from the crooked and inconvenient shape of the logs that are to be cut up. Nature does not always consult the convenience of man in growing trees, and it devolves upon the inventor to construct some apparatus that will hold the most intractable stick as easily and surely as the straight and perfect one. In getting out ship timber, knees, &c, it is particularly desirable to cut the planks according to the natural curve of the wood, and in the ordinary saw-mills, the operation of securing the log is tedious and Involves a great expenditure of time. In the accompanying engraving we present a view of the new and improved chuck, or dog, whereon the most obstinate and awkward stick can be as quickly set in place as a straight and fair one. The correctness of this assertion will be apparent by perusing the subjoined description. The upright casting, A, has a sliding block, B, upon it, which is worked by right and left screws, C; these screws have a peculiar connection, which is shown in an enlarged form in the side figure. The tubular sleeve, D, has two slots, a, one in each end, which receive pins in the ends of the screws. When the upper screw is pushed down into this slot, both screws turn, and the dogs, E, recede from, or advance toward each other at the same speed, but when the top screw is lifted up, the bottom dog remains stationary, and the upper one can be drawn to any point desired. By inspecting the engraving it will be seen that the upper dog has a long slot in it, by which any degree of vertical adjustment is permitted, independent of the screw arrangement; thus providing additional facilities for securing the work.

The upright A, and all its attachments, slides on the ways, F, at the bottom; being moved thereon by a screw and hand wheel, as all other machines of that class are. The carriages may all be moved at one time by the central wheel, G, or the belts can be speedily thrown off, and either one set at varying distances from a straight line, to suit the nature of the work. The dogs also have an offset in them, which enables the sawyer to set lumber intended to be re-sawed, with the greatest facility. The gage, H, is attached to the upright A, by means of screws, and the slots permit of movement in or out, as circumstances require. It will be found useful in resawing or slitting lumber, and also for guarding the log from contact with the dogs while running it on, or the carriage back. The nuts in which the right and left screws work have grooves in them which fit accurately to metallic guides, I, on the edges of the uprights, and by this means they are prevented from twisting or bearing against the screws when the dogs are forced against the log. The end of the lower screw is also carried in a permanent step. These are the principal details of the mill.

Every intelligent person can easily see that the improvements in the upright head are of a practical nature, and such as to give the mill a wide range of usefulness. Any taper can be sawed by moving the knees in or out; and squares, polygons, or many-sided forms can lie as easily executed as the simplest clapboard. For sawing fence stuff, these adjustable dogs are very useful, and will save a large amount of lumber that would otherwise be lost, through the impossibility of holding it securely in a convenient manner for work. Ship knees have been cut on thin machine, and other work of a similar character not usually done upon ordinary circular sawmills. Mr. Hezekiah Alberta, proprietor of a large sawmill near Hackensack, N.J, has used these improvements for a long time and is greatly pleased with them. All kinds of ship and other timber have been cut by the aid of these improvements.

A patent is now pending on this Invention through the Scientific American Patent Agency. Further particulars may be obtained by addressing the inventor, E. B. Requa, care of C. Barnum, 11 Dey Street, N.Y. |

|

1863 E. B. Requa, Saw Mill

1863 E. B. Requa, Saw Mill

|

|