|

Title: |

1863 Article-Arcalous Wyckoff, Eave Trough Machine |

|

Source: |

Scientific American, V 08 #16, 17 Oct 1863, pg. 241 |

|

Insert Date: |

12/4/2013 3:27:42 PM |

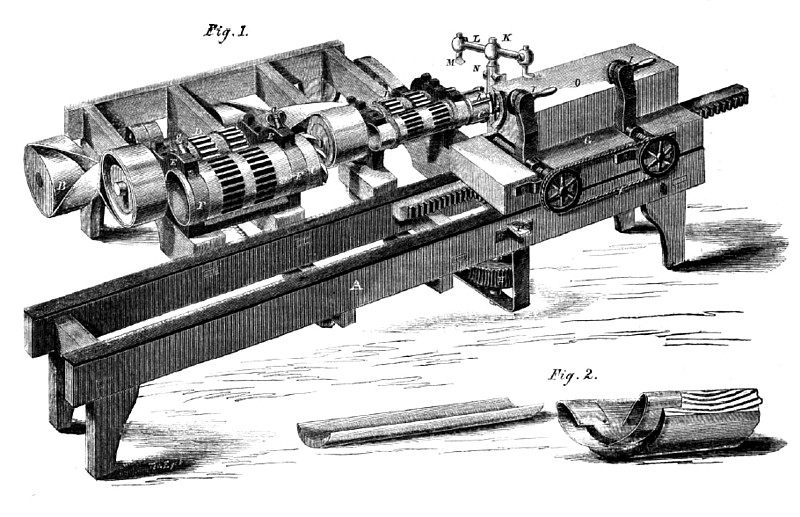

Improved Eave-Trough Machine

The accompanying engraving is an illustration of a new and improved means of manufacturing eave troughs, or the gutters that are suspended under the roofs of houses to carry off rain and drippings. These troughs are made from sound timber, in continuous lengths of any dimensions desired, and are afterward joined together by a metallic coupling inserted in each end, as shown in the small figure. The troughs themselves are cut from planks, and thoroughly dressed, shaped, and finished, in one operation; when done, they are the best that can be produced. A glance at the machine is nearly sufficient to enable any one to understand it; but we append the following description detailing the several parts, so that all may comprehend the arrangement. The frame, A, Is of wood, and has a line of shafting, B, running in boxes at one end; this shaft is driven from any power provided for the purpose. The barrel cutters, C, have mortises in their sides, in which the teeth of the gears, D, mesh ; these latter are driven by belts from the shaft, B, and run in the bearing, E; these bearings have no binders or caps, the same being unnecessary, as the strain is all on the back. A metallic band, F, is provided, however, which keeps the dirt from entering and cutting the bearing, and also prevents the cutters from chattering or vibrating when at work; this band is tightened by the thumb-screws, a.

The stuff to be worked up sets on a sliding carriage, G, which is driven by a rack and pinion; these latter appurtenances are driven from the main shaft, B, by a worm and worm-wheel, H. The stuff is held in place by the two cams, I, having knife edges on their lower sides, which enter the timber and hold it while the cutters are at work; these cams are regularly advanced by the screws, which are connected by the belt, J, passing over both the pulleys.

At the entrance of the stuff to the barrel cutter, there is placed an upright shaft, K (driven from the main shaft), which carries across bar, L, on the top; this bar is adjustable, and has two cutters, M, one in each end, which are also movable, and fastened by set screws. In the vertical shaft itself there are two other cutters, N, fixed, which dress the edges of the timber before it passes to the barrel cutters; the first or horizontal cutters are for planing the sides of the trough. The operation of this machine is as follows:—On being started, the cutters on the vertical shaft dress the staff, 0, while the advancing feed carries it on to the small barrel cutter, which cuts out the hollow of the trough; the chips are swept away from behind the barrel, so that it will not clog by the wings or strips, b, fastened to the barrel itself; the plank continues on until it meets the larger barrel cutter, which separates the trough from the plank and completes the operation. When the carriage is to be run back, the worm-wheel shaft on which this pinion is fastened, Is thrown out of gear by a lever not shown, and the slide, P, in which the upper end of the worm-wheel shaft runs, is retained by a spring on its equivalent; so that the pinion cannot fall into gear and smash the teeth on it and the rack. During these processes no more stuff is wasted than that taken up by the width of the cutters; the small cylinders produce a baton which is useful in building and decorating houses, &c. This is a good feature. The operation above described can be continued infinitely. The machine Is very strong and simply constructed, and as every one can see wi1l do its work to perfection when kept in good order

Respecting his machine, the inventor says:— "It will cut 2,000 feet per day; 1,000 feet of plank will make 2,000 feet of trough, and at the same time it makes 2,000 feet of the half-round batons or strips for roofing. The batons, sold at low figures, will pay all the expense of manufacturing the trough. I have had one of the machines in operation in Elmira for the last three years, and have hardly been able to supply the demand for the troughs. They can be sold at one-fourth the price of tin, and make large profits. These troughs have another advantage over tin—they will last much longer, and can be put up by any inexperienced person."

This machine was patented on Feb. 19, 1861, by Mr. Arcalous Wyckoff, of Elmira, N. Y. For further information address him at that place. |

|

1863 Arcalous Wyckoff, Eave Trough Machine

1863 Arcalous Wyckoff, Eave Trough Machine

|

|