|

Title: |

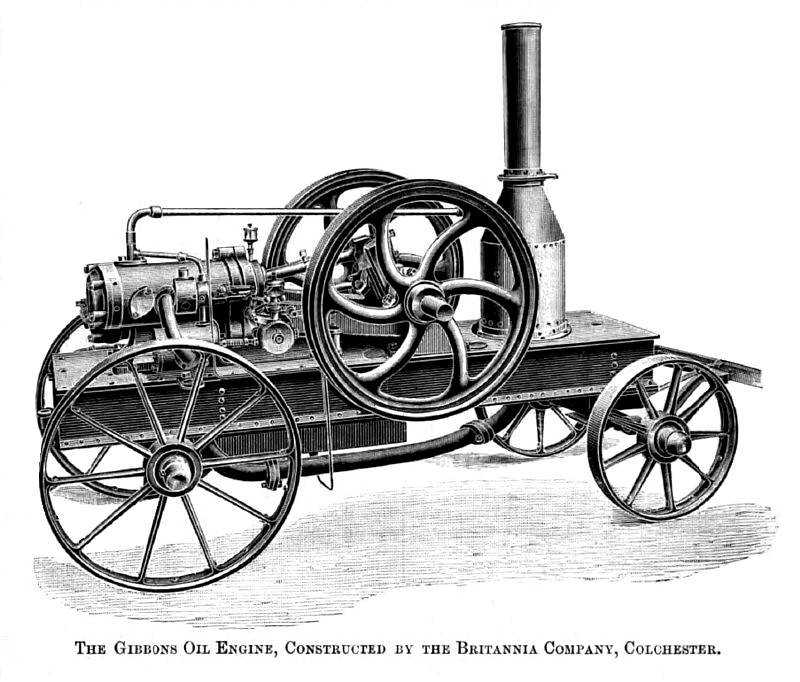

1895 Article-Britannia Co., Gibbons Portable Oil Engine |

|

Source: |

Engineering Magazine, V 59, 28 Jun 1895 pg. 828 |

|

Insert Date: |

11/5/2013 12:43:28 PM |

|

The new engine shown by the Britannia Company is of the portable type, and is illustrated on page 828. It has no separate igniting tube, the heat of the vaporizing chamber firing the charge when the compression is complete. The combustion chamber is not in the line of the cylinder, but is arranged at one side of it, with an ample passage between the two. Around the combustion chamber is a jacket, through which the air required for each charge is drawn, the effect being that the air is heated, and the temperature of the combustion chamber is kept from rising above a faint red heat. There is only one valve both for air admission and exhaust, bat this is supplemented by a piston-like extension, fitting fairly loosely in a cylinder with ports in its walls, as shown in the detail view below. The cylindrical extension is hollow, and is provided with a series of circumferential openings, divided from each other by solid rings. During the compression and combustion stroke of the piston the valve is closed. When the exhaust stroke commences, the cam lifts the mitre valve off its seat to a sufficient extent to bring the lower ports in the cylindrical extension opposite the ports I in the casing leading to the atmosphere, into which the waste gases escape. During this stroke the ports j are closed by the wide upper rings of the cylinder. When the exhaust stroke is completed, the valve is lifted still further, to close the lower ports I and open the upper ports j. Then, on the outward stroke of the piston, air is drawn through the jacket around the combustion chamber, the ports j, the interior of the valve, and the passage i leading to the interior of the combustion chamber. When the charge is complete, the valve t drops on to its seat and the compression commences. The down-stroke of the valve is effected by the springs, shock being prevented by the air cushion t. This cushion is made adjustable to enable the compression to be reduced or prevented while the engine is being started. The vaporizing chamber is an open tube partly projecting into the combustion chamber and partly outside. The outer portion is provided with ribs, and is heated before the engine starts by a lamp. After the engine has been running a short time, the part of the vaporizing chamber within the combustion chamber becomes sufficiently hot to serve as an igniter. It is surrounded by a shield to prevent the entering air from cooling it. The oil is pumped directly into the base of the vaporizing chamber, the amount being under the control of the governor, which actuates a trip gear, by which the throw of the pump is either reduced or prevented, according to the work upon the engine. At moderate loads the engine explodes at each cycle, but with reduced charges. By this arrangement the combustion chamber is always kept hot. |

|

1895 Britannia Co., Gibbons Portable Oil Engine

1895 Britannia Co., Gibbons Portable Oil Engine

|

|