|

Title: |

1900 Article-J. W. Ruger Mfg. Co., Improved Fenner Gas Engine |

|

Source: |

Modern Machinery, V7, Mar 1900, pg. 114 |

|

Insert Date: |

9/18/2013 10:47:30 PM |

FENNER IMPROVED GAS AND GASOLINE ENGINE

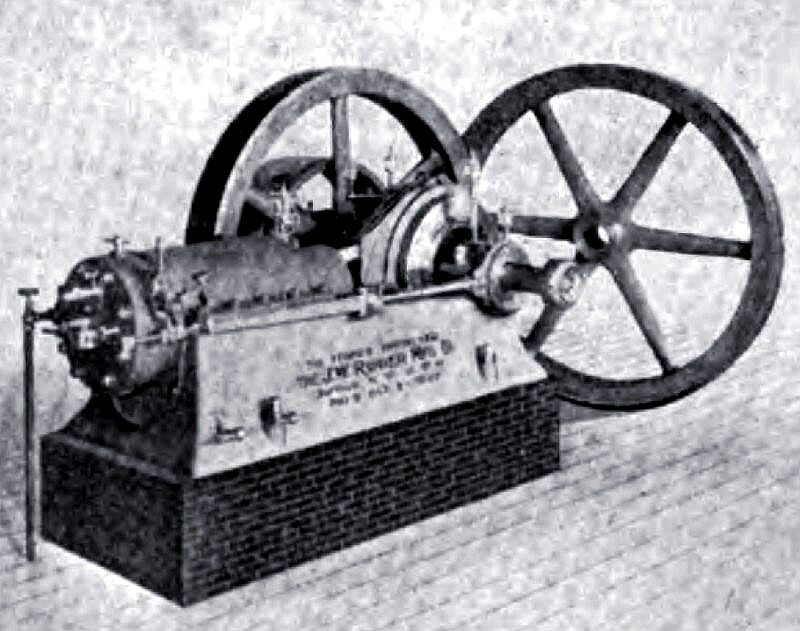

The accompanying cut represents an automatic cut-off, graduated charge gas engine recently placed on the market by the J. W. Ruger Mfg. Co., 50 Perry St., Buffalo, N. Y. The advantages claimed for this machine are that it gives as steady motion as a steam engine and will run a dynamo without a jack shaft or fly wheel on the armature; giving as perfect light as steam power and using the least supply of gas. The needle of a volt meter is held as still as where the best makes of steam engines are used, and shows a variation of less than two per cent In changing from full load to part load, or vice versa. It is a high speed engine and is made either direct connected or belt connected. It makes no more noise, In itself, it is stated, than the best make of steam engines, and makes no noise at the exhaust. A spark igniter is used, the sparker being so constructed that it is almost indestructible and never misses firing the charge. Unusual ease in starting is claimed. The inertia governor in the fly wheel is connected by a rod to a valve that graduates both the quantity of gas and air at each charge, whether at full load or part load; giving the same mixture at all times. This insures an impulse either light or heavy at every second turn of the crank, thereby always insuring steady speed. There is no gearing or cams in the engine to make noise or get out of order. The few parts used in its construction make it not only simple, but not liable to get out of order. Every part in its construction is interchangeable and is accessible without disturbing any other part. The exhaust valve is operated by a mechanical device that holds it wide open after the explosion during one full turn of the crank, thus allowing the cylinder to expel all the burned gas and take In a supply of fresh gas unadulterated by leavings of the previous charge. This mechanism allows the valve to seat without force, so that there is no click or wear on the valve seat. The crank is counter-balanced by a disk securely attached to it, giving it not only a perfect balance but a very neat finish and is covered with a hinged bonnet. This bonnet gives instant access to the crank-pin, whether the engine is running or idle. The system of oiling is automatic at every point where oil is needed, and is so constructed that no oil is wasted or thrown over the engine, or around the room. This feature is said to be peculiar to the Fenner engine. The workmanship and material are of the best the market affords, and the design is neat and attractive, and the engine is a high grade one throughout.

The cut heading this article represents a single cylinder engine, connected to dynamo by belt, and calculated to furnish current for 125 16-candle power lights. About 125 feet of natural gas Is used per hour, or its equivalent in city gas or gasoline, so that the cost of producing excellent light with this engine is unusually low. All engines larger than this size are made upright, with two or more cylinders, and either direct connected or belted. There is an impulse at every turn of the crank, which gives absolutely steady power, making no noise, smoke or dirt, occupying very little room, requiring very little attention and no skilled engineer, these engines are very desirable for a large number of power purposes. A long and tedious set of tests has been made by the manufacturers to find any imperfection or weak points, and they

now offer it to purchasers under a full guarantee. The company's new catalogue gives full and interesting particulars regarding these machines. |

|

1900 J. W. Ruger Mfg. Co., Improved Fenner Gas Engine

1900 J. W. Ruger Mfg. Co., Improved Fenner Gas Engine

|

|