|

Title: |

1903 Article-Christensen Engineering Co., Factory Views (Part 1) |

|

Source: |

Iron Trade Review, V36, 05 Mar 1903, pgs. 79-81 |

|

Insert Date: |

8/23/2013 9:21:04 PM |

The Christensen Engineering Co.’s Plant.

The plant of the Christensen Engineering Co., Milwaukee, Wis., is of considerable interest, owing to the numerous applications of modern shop methods therein and 10 the remarkably rapid growth of the company. In 1896 the first air brake employing a motor driven air compressor, was applied to one of the cars of the Metropolitan West Side Elevated Ry. Co., in Chicago, and early in 1897 the Christensen Engineering Co. was organized to manufacture these air brake equipments for electric cars. The first operations were entirely successful, and other similar apparatus was soon installed in various parts of the country. The extent to which the authorities of electric railways have recognized the value of the Christensen motor driven compressor equipments is indicated by the fact that more than 95 per cent of all the electric roads that have adopted air brakes of any kind are equipped with Christensen apparatus, and there are now over 7,500 of such outfits in service throughout the world.

The remarkable increase in the company's business necessitated a corresponding increase in manufacturing

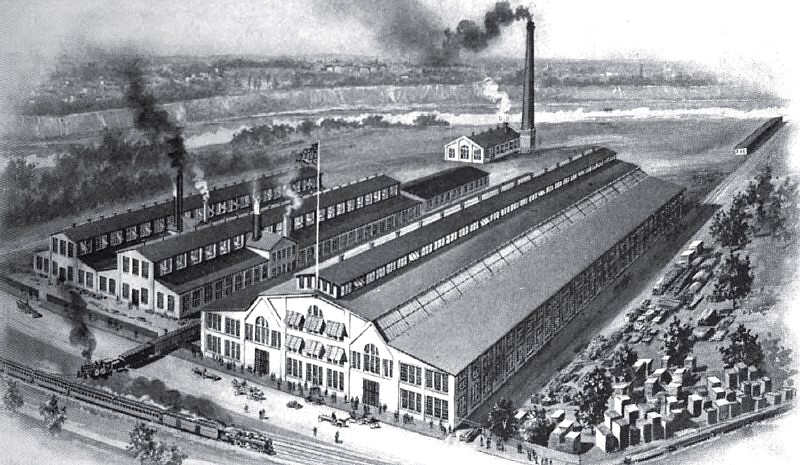

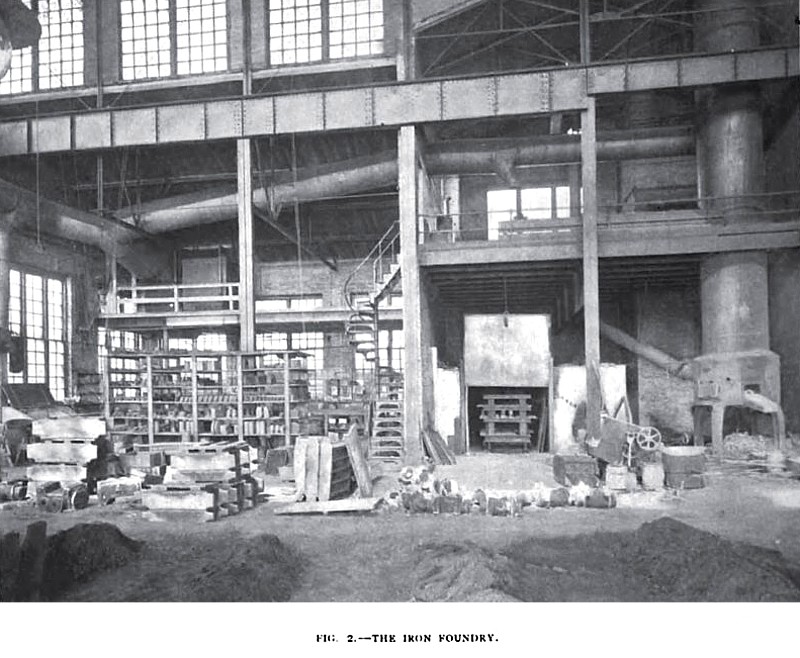

facilities. When first organized the company occupied it 30x70 corner of the Seamless Structural Co.’s plant. Additions to this space were made from time to time, until early in 1899 land was purchased near Riverside Park, Mllwaukee, between the Chicago & Northwestern Ry. and the Milwaukee River. This site contains about 10 acres, and here is located the company's present plant, a general view of which is shown in Fig. 1. The buildings are constructed of brick, and combine the essential features that experience has proved to be of the greatest value in large industrial establishments. The equipment of machine tools, cranes, special machines, etc., is unusually extensive, modern and complete. The original dimensions of the foundry, which was the first building of the present plant to be completed, and which was finished in the fall of 1899, were 100x146 feet, but this has recently been increased by an addition, 50x146 feet. The foundry interior is illustrated in Fig. 2, and a view of the crucible steel foundry, with 6 furnaces in the foreground is shown in Fig. 3. The foundry equipment comprises an extensive adaptation of electrical apparatus in this class of service. The sand mills, tumbling barrels, emery grinders and blowers, are driven by individual, enclosed and dust proof motors, all built by the Christensen Engineering Co. Compressed air is freely employed to operate hammers, tamping tools, etc., in the foundry, and the same motive power is also used for the elevators, which convey metal and coke to the charging platforms of the cupolas. Another application of this force is in connection with the steel furnaces which are arranged for using oil fuel, this being fed to the furnaces by means of compressed air.

The main machine shop is 186 feet in width and the present length is 200 feet. A foundation has recently been completed for a 250 foot extension, which will make the total length 450 feet. This building is three stories high, the central portion being used for erecting purposes and for heavy machine tools. The several floors and other arrangements will be understood more clearly by reference to Figs. 4 and 5, which represent portions of the main shop and pattern shop respectively.

One of the lathe departments is illustrated in Fig. 6. A large number of the machines are driven by belts from small sections of line shafting on the well known “group” plan, each section being operated by an electric motor. The large machine tools are in most cases driven by independent motors, all these motors having been designed and built in the company's works.

A small room in the main building is equipped with such bandages and approved remedies for first aid to the injured as are likely to be occasionally needed in any manufacturing establishment.

The powerhouse, like the other buildings, is an extremely well lighted and fireproof structure. It is 6oxI25 feet. The equipment includes six 130 h. p., Babcock & Wilcox boilers, a 4oo-k. w. 25o-volt, direct current generator, direct connected to an Allis cross compound Corliss engine; a horizontal automatic cut-0E engine with a 90-k. w. direct current generator. There is a room at one end of the powerhouse, 24x60 feet, where the engines and heaters of a hot air heating and ventilating plant are installed. A tunnel, 400 feet long, built of tile conducts the heated air to the machine shop and a return tunnel enables the blowers to obtain an air supply from the shop, sufficient fresh air being supplied from the leaks in windows, etc. The compressed air pipes, electric cables and steam pipes are laid in the return tunnel.

In order to manufacture the large number of motors required to operate the motor-driven air compressors, the company maintained extensive equipment especially suited to the purpose. It was thus but a step to commence the manufacture of larger sizes and other types of electrical machinery. The company therefore decided some time ago to increase greatly its manufacturing facilities and to develop a complete line of electrical machinery of high grade. This plan has been followed out and a large number of generators and motors are now under construction. Although it is but a few months since the company began to sell electrical apparatus, the machines are already beginning to attain the reputation long been accorded to their air brake apparatus. Numerous extensions and improvements have been made and are being made in order to supply the necessary facilities and handle the constantly increasing business. During the past few months several large machine tools and cranes have been installed and the present equipment is sufficient to permit the manufacture of direct current generators up to 1000 k. w. and alternators up to 1500 k. w. capacity. As the principal products of the company are air compressors and electrical machinery it is natural that electric and compressed air appliances are used extensively throughout the works.

Work has been commenced on a three story office building, 66x200 feet. A warehouse, 50x200 feet, has also been planned and work on this structure will be started this spring. |

|

1903 Christensen Engineering Co., Factory View, Fig. 1

1903 Christensen Engineering Co., Factory View, Fig. 1

1903 Christensen Engineering Co., Iron Foundry, Fig. 2

1903 Christensen Engineering Co., Iron Foundry, Fig. 2

1903 Christensen Engineering Co., Crucible Steel Foundry, Fig 3

1903 Christensen Engineering Co., Crucible Steel Foundry, Fig 3

|

|