|

Title: |

1884 Article-Pennsylvania Agricultural Works, Factory Views |

|

Source: |

Scientific American, V 50 #2, 12 Jan 1884, pgs. 15 & 20 |

|

Insert Date: |

8/14/2013 1:36:21 PM |

THE MANUFACTURE OF STEAM ENGINES AND AGRICULTURAL IMPLEMENTS.

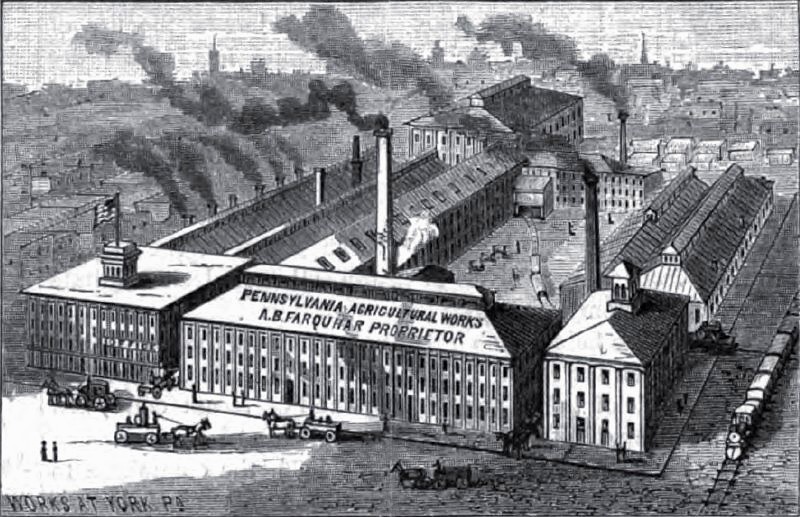

The celebrated manufacturing town of York lies in the famous agricultural region of the Codorus Valley, in Southern Pennsylvania, between Philadelphia and Baltimore, and is about five hours by rail from New York city. Its most important industry is the manufactory of steam engines and agricultural machinery known as the Pennsylvania Agricultural Woks, owned and managed by A. B. Farquhar. These works were founded by Mr. Farquhar a quarter of a century ago, and additions have been made from time to time until they now fairly rank as one of the most complete and extensive establishments, for the production of machinery and implements, not only in the United States but in the world. The works were designed especially for the manufacture of improved machinery and agricultural implements, with tools adapted to every part of the work; and having the benefit of abundant skilled labor at moderate cost (swing to low rents, good markets, and healthy location), and being contiguous to the vast lumber, iron, and coal regions of the country and in easy access of the great cities of New York, Philadelphia, and Baltimore, the proprietor is enabled to offer superior advantages to those needing first class agricultural tools and machinery.

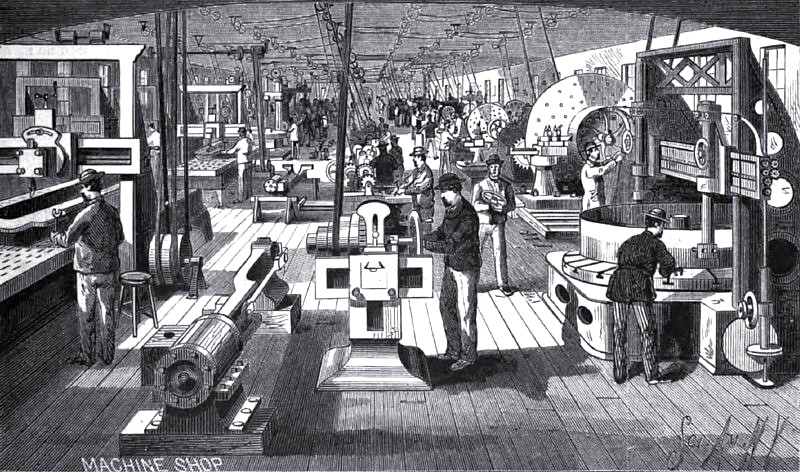

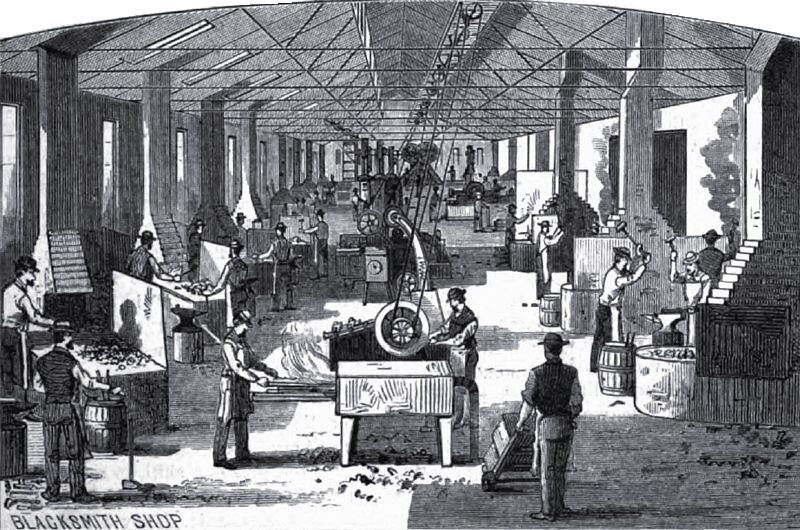

The works cover a number of acres, and embrace machine, engine, and boiler shops, bolt and nut factory, planing and saw mills, foundries for brass and iron, forging, shearing, and polishing rooms, besides warehouses, lumber yards, etc., all complete in itself. Among the specialties are steam engines, saw mills, thrashing machines, plows, agricultural steels, cultivators, grain drills, corn planters, horse powers, etc., in almost endless variety. Some idea of the magnitude of the operations may be formed from the fact that the weekly consumption of iron now averages over 150,000 pounds, and of steel fully 10,000 pounds, and of lumber from 50,000 to 100,000 feet.

The business shows an annual average increase of from fifteen to twenty per cent, necessitating frequent additions to both buildings and machinery. This is a direct result of the principle governing the whole concern—only the best material and most skilled labor are employed, and everything sold is fully warranted; not a single detail is risked by bad work, and if a mistake or defect occur it is promptly made good. The utmost pains are taken at every point to turn out only work of the highest order. As a natural consequence the trade now extends over the habitable globe, and at the time of our visit orders were being filled for nearly every State in the Union, and shipments being made to remote corners of the world. Large additions to the works have been made within the past year, and machinery of the most improved pattern known to the trade has been introduced for the manufacture of each part of the work.

The best relations exist between proprietor and employees, and there has never been a strike in the works. The superintendents and workmen take almost as much interest in the success of the business and quality of the machinery turned out as the proprietor.

No traveling men are employed, the business relying on quality for its maintenance and increase. It is the aim of the proprietor to give full value to all purchasers and to make it a benefit to them to deal with him, and as proof that his efforts in this direction have been successful he points with just pride to his immense and rapidly increasing business. The works ran full handed during the entire period following the financial depression of 1873.

The most competent experts are employed in the several departments, and large sums are expended in order that they may post themselves concerning the wants of different sections and keep the manufactures up to the highest standard of excellence. Many medals from the world's fairs of Europe, our Centennial and Slate fairs, attest the high regard in which the machinery is held.

A bird's eye view of the principal factories is shown in our engraving, each department being arranged with special relation to the business pertaining to it. Although it is impossible to give a conception of the size and completeness of the works, some idea may be formed when we say that the total floor space approximates half a million square feet. The view on our title page gives an idea of the arrangement of the shops, some fifteen in number, and some of the leading machines and implements. The buildings are all constructed of brick and iron, with slate or metal roofs. A complete system of water mains, hydrants, and hose pipe protects the works from fire. The wood-working shops are supplied with a system of perforated pipes, so arranged that the entire structure may be deluged with water by turning one wheel. The factories are all lighted by electric lights. Tracks connect the different buildings with the five railroads centering at York. The very best work can be furnished at the lowest price, since all parts of the machinery and implements are made here—the nuts, washers, bolts, steam fittings, etc., belonging to the engines, and the handles, beams, castings, steels, bolts, etc., belonging to the plows and implements.

In addition to the works located at York, the large and rapidly increasing Southern trade necessitated the opening of the branch store and factory known as the Central City Iron Works, in Macon, Ga., now one of the most complete in the South. The large export trade is handled from the store in New York city.

Among the well-known specialties manufactured at these works are the Farquhar Ajax traction and portable engines (the fire-boxes are steel, and the boilers have a remarkable record, not one having ever exploded); the vertical boiler with submerged tubes, arranged with wheels when desired; the Farquhar separator with self-regulating blast, saving every grain; saw-mills with patent feed, set works and dogs of most improved kind. Among the leading implements manufactured here are the Penna. drill and corn planter, with perfect force feed and phosphate attachment, and Farquhar's celebrated wheel or sulky plow.

Farquhar's Ajax Traction Engine has several important patented advantages. The boiler is made of steel, and is so constructed that it is impossible for the crown-sheet to become exposed, even on the steepest grades. A steam guiding attachment enables the engineer to steer with ease, by the simple movement of the lever. The wheels are of a most improved pattern, strong, durable, and of a handsome design. Springs are placed in the hubs of the wheels, acting as a cushion between the engine and gearing, and supporting the weight and avoiding jarring when passing over an obstruction. A neat cab covers the platform, protecting the engine and engineer from storms or hot sun.

The Ajax Portable Engine is of the center crank type, and possesses strength combined with simplicity. The pedestals and crosshead guides are cast solid with the bed-plate, thus making it impossible for the engine to work out of line or give. The cranks are made of the best steel. The fireboxes of the boilers are made of steel, of the same brand as that used by the Pennsylvania Railroad in their locomotives. The rest of the boiler is made of the best charcoal iron.

The Vertical Engine is very popular, being light, convenient, and cheap, and is as good as the horizontal where light power, from two to six horse, is required where used for thrashing grain or other portable purposes. The boilers are provided with two trunnions and wheels. The lubes are submerged. The engine and boiler are carefully made to insure durability and strength.

In the Farquhar Improved Saw Mill the patent feed, set works, and dogs and head blocks are all of improved form; the saw shaft is stee1. It is stated that some of our large lumbermen have found it economical to throw out their old mills and substitute this.

The Farquhar Separator is so well known as to need but little description. It was awarded the first premium and medal at the Centennial and Paris expositions on account of its lightness of draught, rapidity and economy of work. Owing to its self-regulating blast, which cleans the grain ready for market, the chain elevator, which cannot be choked, steel shafts and spikes, it possesses advantages of the highest order.

Farquhar's Wheel or Sulky Plow does work better, cheaper, quicker, and with infinitely more ease than the walking plow. Its special advantages are simplicity of construction, effective work and steel beam. It has a positive self-lifting attachment, adjustable hub box, light, strong, and handsome wheel, and may be easily and readily adjusted from two to three horses. It is constructed wholly of iron and steel. It has sliding axles, is light draught and is most durable, although weighing less than the others in use. In construction, adjustment, and ease of management it is superior.

Many other improved implements were being turned out in great quantities when we visited the works. We have only space to speak of a few which particularly attracted I attention. The Geddes hinge harrow is one of the best in use. It draws from the center, is easy on the team, and being hinged it works as well on uneven laud, and is easily lifted when in motion, to discharge weeds, etc. It

is strong and durable, and can be doubled in a portable form. The teeth are prevented from getting loose by being fastened with nuts and washers. Harrows constructed upon other plans, but all showing the same degree of good workmanship, were noted.

The Farquhar improved cotton planter is very simple and perfect in its operation, dropping the unrolled seed with remarkable regularity and in any desired amount. The Keystone corn planter will plant from ten to twelve acres of corn per day, dropping kernels in drills or in hills, at any desired distance apart, and sowing at the same time, if needed, any kind of pulverized fertilizer. The Pennsylvania force-feed fertilizer grain drill will not only sow the grain evenly, but, what is an equally important feature, it will distribute the phosphate with the same precision, doing the work without any loss of either seed or fertilizer.

The Farquhar Hoffheins mower and reaper possesses many points of excellence. The frame being of solid iron and very compact holds the shafts securely in position and is supported by two ground wheels, either or both of which drive the machinery. The self-rake, moving automatically, will make the bundles at regular intervals, their size being regulated by means of a treadle convenient to the driver's foot. The height of cut can be regulated while the machine is iu motion; the guards can be thrown down, so as to run under the fallen grain, or elevated to pass obstructions.

Farquhar's climax horse-power, for thrashing, ginning, and general farm use, is triple geared, the strain being divided so as to prevent breakage or wear. All the gearing is connected by one strong iron frame ; the levers are so arranged that the strain of the team is thrown upon iron braces, and can be taken off or put on in a moment without loosening a bolt. All the boxes are self-oiling. This horse power is strictly portable and can be quickly and easily set up by ordinary farm laborers. Corn shellers adapted to band or horse power, farm mills, standard grinding mills for corn, wheat, and other grains, fodder cutters, cider mills, farm and freight wagons, etc., are turned out in almost endless variety.

We have not the space to even enumerate them. All the various parts of the agricultural implements and the steam engines and boilers—including bolts, nuts, thrasher spikes, wrenches, plow irons, and forgings of all descriptions, and valves, cylinder lubricators, water gauges, air cocks, steam whistles, inspirators, etc.— are turned out at these works.

Further particulars of this manufactory and the work it produces may be obtained from the large illustrated catalogue, which will be furnished upon application by the proprietor, Mr. A. B. Farquhar, York, Pa. |

|

1884 Pennsylvania Agricultural Works, Factory View

1884 Pennsylvania Agricultural Works, Factory View

1884 Pennsylvania Agricultural Works, Machine Shop View

1884 Pennsylvania Agricultural Works, Machine Shop View

1884 Pennsylvania Agricultural Works, Blacksmith Shop View

1884 Pennsylvania Agricultural Works, Blacksmith Shop View

|

|