|

Title: |

1902 Ad-A. Mietz, -Mietz & Weiss Kerosene Engine |

|

Source: |

The Engineer, V39, 01 Jan 1902, pg. 44 |

|

Insert Date: |

12/15/2013 7:56:00 PM |

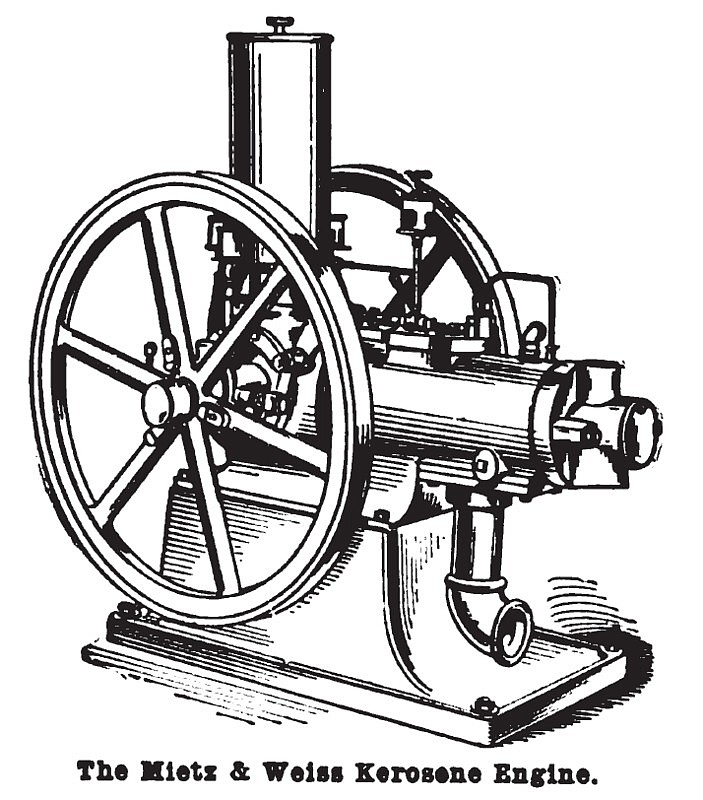

The Mietz & Weiss Kerosene Engine.

The accompanying illustration is a side view of the Mietz & Weiss kerosene engine, built by August Mietz, 128-138 Mott street, and 87-89 Elizabeth street, New York. These engines are adapted to the use of any gas, either natural or artificial, and common kerosene. The working method is the same for either of these fuels, the construction differing only in the mechanism for injecting the fuel into the cylinder.

The engine receives at full power an impulse at each revolution. The compression and the burning of the mixture, and the expulsion of the exhaust, are all performed in the most direct and simple manner at every revolution.

The crank is enclosed in a neat crankcase which excludes all dust and dirt, while the absence of cams, valves and side shafts lessens the liability to accident. The rigid crank shaft bearings, perfect lubrication and the prevention of disagreeable odors caused by the slightest leakage past the piston, which is often noticeable in open cylinder engines, are some of the desirable qualities embodied in this design.

The governor is very simple and effective. It is arranged to operate from the main shaft without belting or side shaft, and regulates the supply of fuel to the actual power used, maintaining a steady and uniform speed of the engine.

Ignition is effected by means of an improved hot tube that is practically indestructible by heat. It can be replaced at a trifling cost in case of accidental breakage, no cleaning or renewal being necessary.

Ignition in the kerosene engine is effected by compression, and is entirely automatic. Provision is also made for a kerosene blue burner, furnished with each engine, to be used for a few minutes before starting. The absence of a slide valve, electric spark and the tube igniter is a feature especially appreciated by woodworkers and others, on account of the inflammable nature of their products.

Lubrication is positive and automatic, the oil for this purpose being forced by pressure to the parts needing lubrication as long as the engine is in motion. The boxes at both ends of the connecting rod, as well as the main shaft bearings, are made of phosphor bronze, with large wearing surfaces. The pressure in the crank chamber is alternately above and below the pressure of the atmosphere and the oil is forced up from the reservoir through the sight feeds, where the drops are visible and can be regulated.

Ring oilers are employed for the main shaft bearings.

These engines are built for every service to which a gas or gasoline engine is at all adapted and in sizes ranging from ½ to 100 brake horsepower. |

|

1902 Ad-A. Mietz, -Mietz & Weiss Kerosene Engine

1902 Ad-A. Mietz, -Mietz & Weiss Kerosene Engine

|

|