|

Title: |

1872 Article- Philip S. Justice, Dead Stroke Power Hammer |

|

Source: |

Scientific American, V 26 #6, 03 Feb 1872, pg. 82 |

|

Insert Date: |

3/6/2013 7:16:31 PM |

Dead Stroke Power Hammer.

The peculiar advantages claimed for this hammer, which has, in a less perfected form, been before the public for some years, are as follows:

It strikes a square true blow at all times and under all circumstances. It can be run at a high speed without danger of breakage. It has neither cylinder, valve, nor piston rod, fruitful sources of expense in steam and atmospheric hammers.

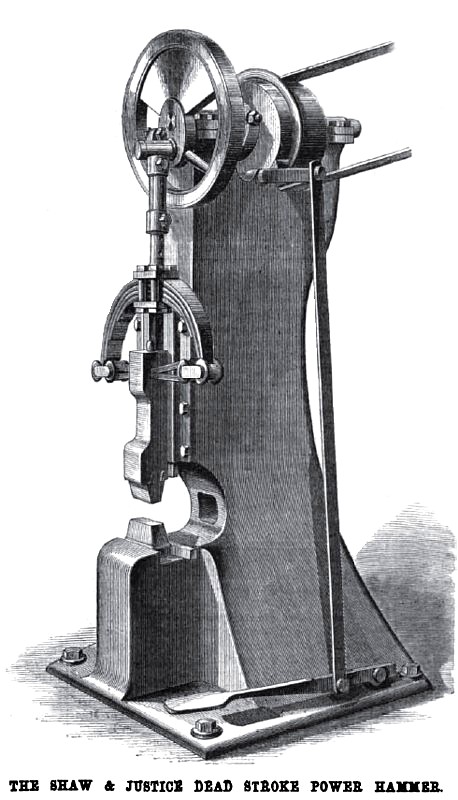

The improved form of this hammer is shown in the accompanying engraving.

The ram, or striking part of the hammer, suspended by an elastic belt on the extreme points of a semicircular steel spring, obtains for it, it is claimed, a far more effective blow than is given by any other hammer of the same ‘weight and stroke.

The upper part of the steel spring is connected by a rod with a crank pin, which, being set in motion by belting from any convenient line of shafting, gives the reciprocating movement necessary to raise or lower the ram in its guides with a speed and force entirely regulated by the friction pulley, which is always under the control of the operator.

Another peculiarity of this hammer is that the rebound is taken up, by the spring and belt on which it is suspended, before reaching the working parts above it. In this way the shaft bearings, crank pins, and set screws are preserved from breaking.

The convenience of this hammer is a great point in its favor, for, although it may readily be adjusted to work exclusively on thick metals, yet for ordinary work, a 50 lb. hammer, for example, will strike good alternate blows on a 3 inch or 3/8 inch bar without any change in the adjustment. This is readily understood when it is explained that the ram, in ascending, has a stroke inside the spring, into which it rises by the flexibility of the leather belt to which it is attached, and the compression of the points of the spring as the ram is rapidly forced up between them.

It will be observed that the anvil block and sole plate are all connected with the frame in one piece, excepting in hammers in which the ram weighs 1,000 lbs. and upward.

Great improvements have recently been made in this hammer. The friction gear now supplied renders it much more controllable, and permits a tight belt to be run at any angle.

Persons using loose belts, which are constantly flapping about and have to be run at a certain angle, will appreciate this change. The frame is much stiffer, than it formerly was, by reason of its shape; the guides are bolted on, and the gib at the hack of them discarded. The dies in the ram and anvil block are all keyed in, and the workmanship is good in every respect.

A new method of fitting the crank pin in the 25 lb. hammer has been devised, by which the stroke can be changed from 12 inches to 8 inches, thus permitting the same hammer to be run very rapidly on light work, as small as 3/8 inches in diameter. By this arrangement, the machine may be run at a very high rate of speed, and the 15 lb. and 25 lb. hammers combined in one machine, thus giving a much greater range of stroke.

For manufacturers taking up a new line of work, requiring a larger hammer than they at first anticipated, this 25 lb. hammer is considered a superior tool.

These hammers are used in the Government workshops of the United States, France, and Russia, and have been sent to all parts of the United States. Many are in use in England, Scotland, France, Belgium, Holland, and Russia. A prize medal was awarded to it at the Exposition of Paris, as well as at the Lowell Mechanics’ Association.

A small hammer, to be attached to walls, is the same in principle as that shown, but has advantages that the latter has not; as, for example, greater space between the anvil block and the back of the frame. This renders its useful for straightening saw plates or frames of any kind, planishing copper or other metals, and a. variety of purposes which will occur to the mechanical reader.

Upward of two hundred and fifty of the standard hammers are now in use, and are said to give satisfaction.

It was originally patented Feb. 27, 1860, but many improvements have been since added. For further particulars address Philip S. Justice, manufacturer, 42 Cliff street, New York, or 14 North Fifth street, Philadelphia.

Patents #52,894 & RE2,398 |

|

872 Shaw & Justice, Dead Stroke Power Hammer

872 Shaw & Justice, Dead Stroke Power Hammer

|

|