|

Title: |

1902 Article-Niles Tool Works, Rail Drilling Machine |

|

Source: |

The Engineer Magazine, 26 Sep 1902, pg. 312 |

|

Insert Date: |

1/5/2013 7:36:09 PM |

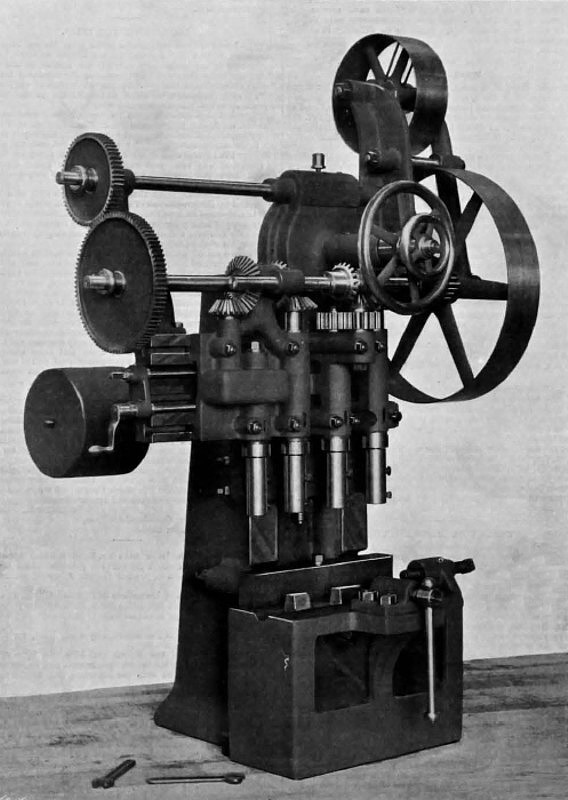

RAIL DRILLING MACHINE

We illustrate above s machine for drilling the rails of electric tramways and railways. Three of the spindles make the holes for the fish-plate bolts, whilst the fourth drills the hole for the bond wire. These machines are generally used in pairs, one right and one left. They are placed in a line at a little more than the length of e rail apart, and one end having been drilled, the rail is pushed along into the clamp of the other machine. Thus the turning of the rail, end for end, is obviated. The main spindles are adjustable by screws from 3½ in. to 9 in. between centres, and will drive 1¼ in. drills. The bond wire spindle is 6 in. from the main drill, and usually drills 5/8 in. holes. The machine has power for driving all drills at once. All the spindles are mounted on one sliding head, which is counterweighted and has power down feeds with friction release and quick hand movements. The rail to be drilled is set endwise against an adjustable stop and clamped in place by a vice, so that all holes will come alike. The counter pulleys are 24in. in diameter for 5in. belt, and run 120 and 180 revolutions per minute. The machine is made by the Niles Tool Works Company, of Hamilton, Ohio, U.S.A.

Image Courtesy of Grace's Guide

http://www.gracesguide.co.uk/images/7/74/Er19020926.pdf |

|

1902 Niles Tool Works, Rail Drilling Machine

1902 Niles Tool Works, Rail Drilling Machine

|

|