|

Title: |

1911 Article-A.D. Baker Company, 16 H. P. Steam Road Roller |

|

Source: |

Municipal Journal, V31 21 Dec 1911 pg. 808 |

|

Insert Date: |

12/29/2012 1:24:34 PM |

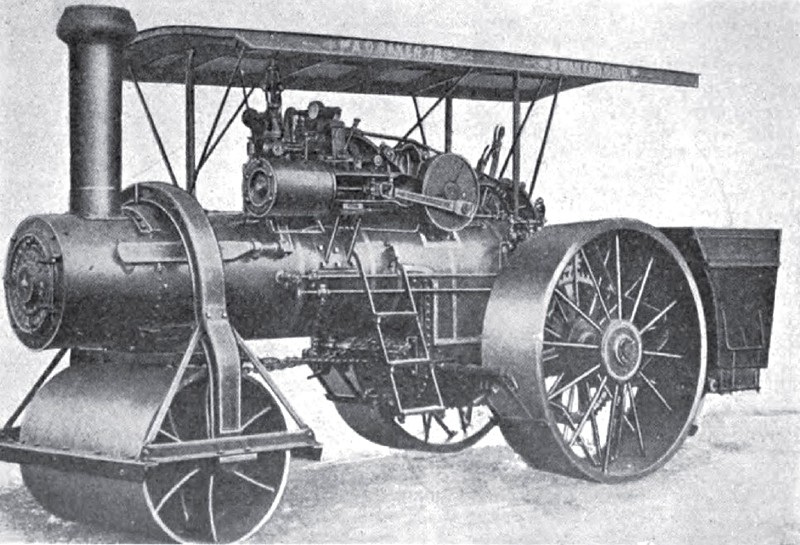

Baker Steam Road Roller

The A. D. Baker Company, Swanton, O., manufacture a steam road roller for which great economy of steam and power are claimed. The roller is equipped with a 16 hp. engine and boiler. The cylinder is 8¾ inches in diameter by 10¼-inch stroke. The driving rolls have a face of 18 or 20 inches; they are 68 inches in diameter and are beveled so as to give the usual crown to the road. The rolls are of semi-steel, 2½ inches thick. The front roll is in four sections and is slightly concaved.

One of the peculiarities of the machine is the yoke design. This yoke is held in place by two sliding pivot bearings, one on top of the boiler and one underneath, being about 36 inches apart and giving a good leverage on the front rolls. These pivot bearings slide in an annular groove, which is accurately machined. This design permits of great flexibility, allowing the rolls to adjust themselves to any unevenness in the ground without any appreciable strain. The yoke is mounted far back from the front end of the boiler, which permits a much shorter wheel base, larger boiler, accessibility to the flues' and proper distribution of weight. All pinions are of open hearth steel and all other gearing is made of semi-steel. The machine has a compensating gear, which permits turning at all times in either direction, right or left. The speed may be varied from less than a mile to 2½ miles per hour. The firebox has a water-bottom, which gives ample space for sediment to settle. The engineer has control of the draft at all times and the draft is practically airtight.

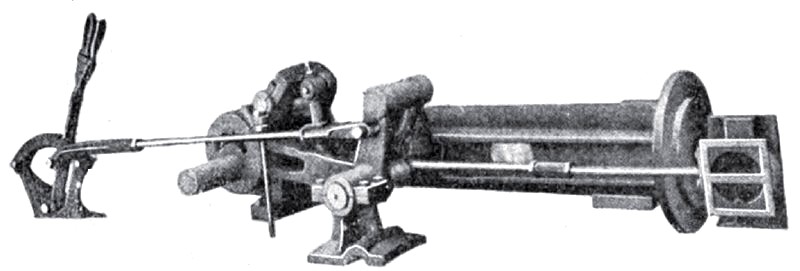

The following details of the valve gear are the same both in the Baker steam roller and the Baker traction engine.

The valve gear of the engine has an improved valve gear which is claimed to be more economical of steam than any other reverse valve gear. One horsepower per hour from one and a half pounds of coal is possible in use of stationary boilers and engines with scientifically correct arrangement of valve gears, while from four to five pounds per hour is quite common in ordinary stationary engines and boilers. The same wide range of difference is true in traction engines with well and poorly constructed valve gears and boilers. The most economical engine is the one, which provides for the most nearly instantaneous admission of steam to the cylinder and a cut-off that acts quickly.

The Baker valve gear opens the ports full, wide open, by the time the piston has traveled three-eighths of an inch from either cylinder head. The cut-off is variable, permitting the use of the steam from one to six expansions by simply hooking up the reverse lever at the point desired.

The valve gear is of the reverse type. All strains between eccentric and valve arc in a straight line, therefore none of the bearings can wear out of true. There are no sliding joints, rollers, cogs or cam devices to get out of order. All bearings are very large, all working joints have adjustable brass boxes, and all wear can be taken up by simply turning a set-screw against the brasses.

As, by the use of the live-steam jacket around cylinder, there is no condensation to overcome; it is possible to cut off at three-eighths of the stroke instead of at the usual live-eighths, giving more expansive force of the steam than would otherwise be possible. By the quick admission of steam the benefit of a sudden impulse is obtained, almost like that caused by an explosion, imparting great energy to the piston. The port opening is large, and, with quick admission, gives another decided advantage, admitting steam in volume immediately upon the opening of the ports. |

|

1911 A.D. Baker Company, 16 H. P. Steam Road Roller

1911 A.D. Baker Company, 16 H. P. Steam Road Roller

1911 A.D. Baker Company, 16 H. P. Steam Road Roller (Valve Gear)

1911 A.D. Baker Company, 16 H. P. Steam Road Roller (Valve Gear)

|

|