|

Title: |

1900 Article-Betts Machine Co., Extension Boring & Turning Mill |

|

Source: |

English & American Lathes, 1900 pg 119 |

|

Insert Date: |

12/19/2012 1:11:18 PM |

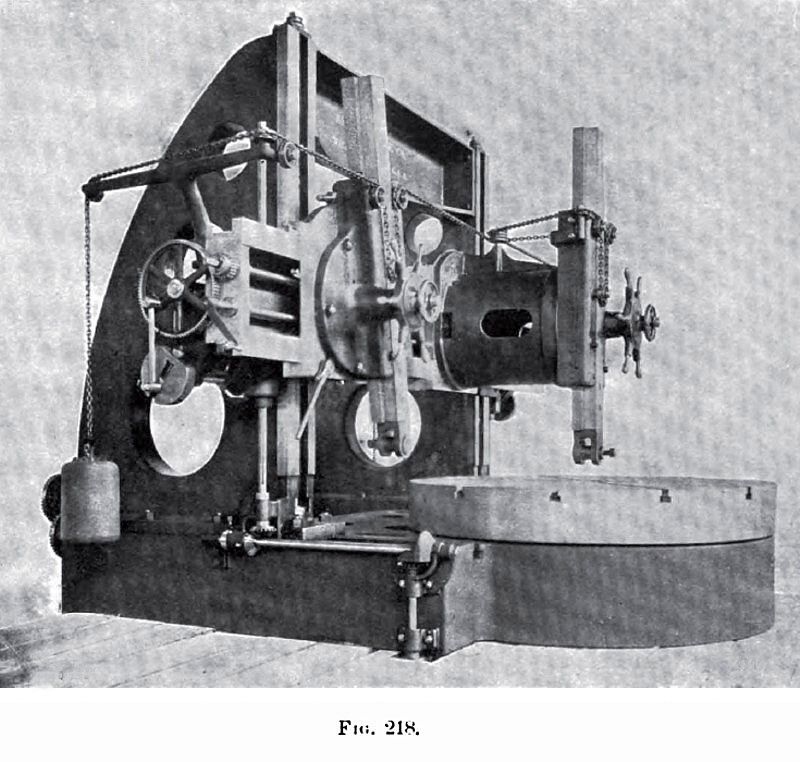

The Betts Machine Co., of Wilmington, Del., make a specialty of the vertical boring and turning mills, in capacities ranging between 5 ft. 5 in. diameter, by 3 ft. 6 in. high, and 14 ft. 5 in. diameter, by 8 ft. high. A feature of some of these mills is that they can be enlarged by extending the bed-plate backwards, and moving the uprights back on the enlarged plate. A blocking-out piece is fitted to one of the saddles, or an independent boring-head secured to the cross-rail. The changes of speed of the table are numerous, numbering twenty in the smallest machine, and sixty in the largest, the intermediate sizes having twenty, forty, and sixty changes.

Fig. 218 shows one of the "extension" boring and turning mills, of the Betts Machine Co., in which the uprights can be slid back on the side-wings of the base-plate to enlarge the swing. The extension machines are made in sizes of 6 ft., extending to 8 ft.; 7 ft., to 10 ft.; 10 ft., to 16 ft.; and 14 ft., to 20 ft.

The figure shows a bloc-king-out piece attached to one of the saddles, so bringing the spindle out to the centre.

These enlarging mills have the same height, same size table, same power, and same number of speeds as the size from which they are increased. They differ from them in having an increased length of cross-rail, in having an elongated bed-plate, upon which the uprights and cross-rails move back, and blocking-out piece (or independent boring-head for the extension boring on the 10 ft. increased to 16 ft. mill).

The cost is little more than that of the fixed mill, while the act of enlarging occupies but a few minutes.

The saddles, in both mills, have a long bearing on the cross-rail, with rapid hand-movement by rack and pinion. The face of the saddle is provided with a circular tee-slot, which receives the bolts, and these secure the index-plates or swivels. The index-plates carry the tool-spindles, or cutter bars, in a slide on their face, and these are also provided with a square lock, as in the case of the cross-rail. The tool-spindles are provided with a rack and pinion for quick motion up or down, as well as for feeding; the ends of the spindles are provided with a special tool-holder, in which the tool can be fastened and adjusted with m much ease and as great range as in a lathe. Each spindle has quick hand-return, and is counterbalanced in all positions, and the counterbalance does not interfere in any way with the setting of the index-plates. Two complete sets of feeds are provided, making each saddle as independent of the other as though on separate machines. The feeds are vertical, horizontal and angular. These feeds cover a large range, are large in number, ranging from twenty to thirty-six in the different sizes, and have ample power; they are by hand or power in all directions. The cross-rail is moved by power in all sizes.

In many cases it is desired to cut key-ways, etc., without removing the work from the mill; for this purpose, the Betts Machine Co. furnish one tool-spindle with an attachment which gives it an automatically reciprocating motion, thus converting it, temporarily, into a slotter. This attachment does not interfere with the tool-spindle, except when in use, and can be attached or detached in a few minutes. It will cut either taper or straight, and has a stroke almost equal to the movement of the spindle. |

|

1900 Betts Machine Co., Extension Boring & Turning Mill

1900 Betts Machine Co., Extension Boring & Turning Mill

|

|