|

Title: |

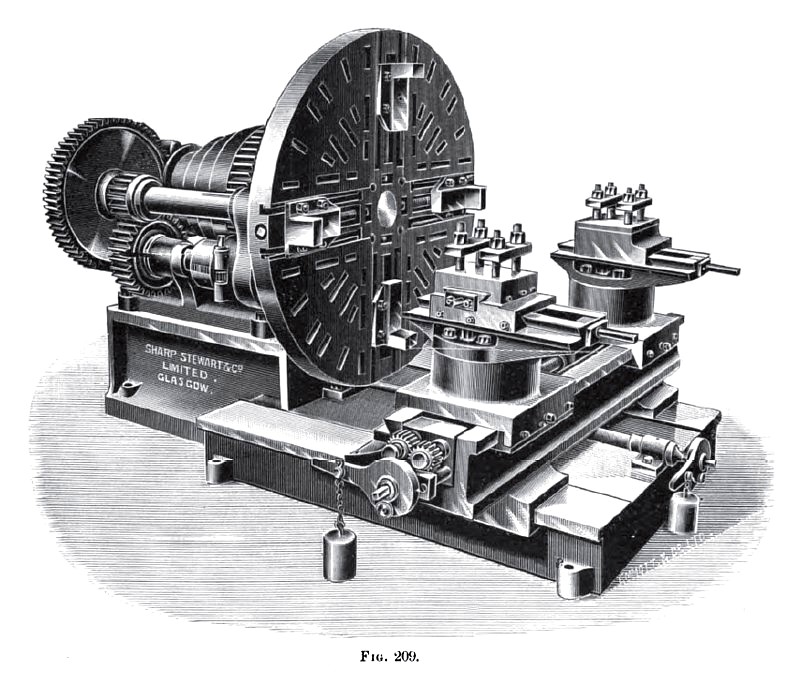

1900 Article-Sharp, Stewart & Co., Ltd., Face-Plate Lathe |

|

Source: |

English & American Lathes, 1900 pg 112 |

|

Insert Date: |

12/18/2012 12:07:25 PM |

Surfacing or face-lathes are used for turning work of large diameter, and of no great length. Work done in them is turned either on the face-plate only, or between centres. Fig. 209 illustrates one by Sharp, Stewart & Co., Ltd., triple-geared, with a face-plate 5 feet diameter, to admit work 5 feet diameter, and 2 feet 6 inches wide. The headstock is bolted to a bed, one end of which—that immediately under the headstock—is generally fixed on masonry or concrete, as is also the base-plate of box section, which carries the cross-slide. Or, in some lathes two wings which carry the cross-slide are bolted to cross-girders, and the same cross-girders carry one end of the bed on which the movable poppet slides, the other end of the latter being carried on a third cross-girder. The girder framing then forms a wide gap, within which the work swings. The cross-bed travels along the top-faces of the base-plate, or of the side-girders, and the maximum distance between its front face and the face of the face-plate measures the capacity of the lathe in that direction, which may be 6 feet or 7 feet maximum. In the series of lathes illustrated by Fig. 209, the diameters which can be swung range from 6 feet to 14 feet, and the widths from 3 feet to 7 feet. The cross-bed is traveled along the side-girders by means of a screw or screws, actuated simultaneously by a cross-shaft through mitre-wheels. It carries two compound slide-rests with self-acting motions, and in many cases a loose headstock for boring. The slide-rests are either worked by hand, or by means of an eccentric on the main spindle end, and chains and levers. The poppet is moved to and fro by means of a ratchet. The driving-gear consists of a speed-cone with back-gear, actuating a pinion, which gears into a ring of teeth on the back of the faceplate; turning the face-plate, and with it the main-spindle to which it is attached. In large face-lathes the internal driving ring is bolted on. The face-plate also is fitted with movable jaws. In some of the face-lathes the mandrel-nose is formed into a flange, and the face-plate is bolted to this. It is also bolted on similarly on the chuck-lathes, which are of smaller size.

The dimension of centres of a surfacing and boring lathe is given as the swing of the lathe, that is twice the distance from the centre of the mandrel to the top-face of the bed. If a lathe were of 20-in. centres, it would be a 40-in. swing lathe. The height of the headstock is less than the working centres, because it is carried upon a raised portion at the end of the bed. In a 20-in. centre lathe the headstock would be about 12-in. centres.

Surfacing and boring lathes are generally treble-geared, and generally, too—always in large lathes—the driving-cones are distinct from the main-spindle, being brought to one side of the headstock. The feeds of this class of lathe are confined within certain limits, and their ranges are conveniently given as proportionate to the rate of revolution of the spindle. They will range usually from one-twentieth and one-tenth to one fourth of an inch per revolution.

Lathes used for boring and turning wheel-centres and tyres consist essentially of a massive headstock and short bed only, long enough to receive two slide-rests in front of the work. The face-plate is fitted with ordinary jaws. In some lathes of this type worm-wheel teeth are cast round the rim of the face-plate, and the driving takes place thus through a worm beneath, driven by belt-pulleys. The worm runs in an oil box. |

|

1900 Sharp, Stewart & Co., Ltd., Face-Plate Lathe

1900 Sharp, Stewart & Co., Ltd., Face-Plate Lathe

|

|