|

Title: |

1900 Article-Hulse & Co., Ltd., Heavy Break-Lathe |

|

Source: |

English & American Lathes, 1900 pgs. 110-111 &162 |

|

Insert Date: |

12/17/2012 9:15:50 PM |

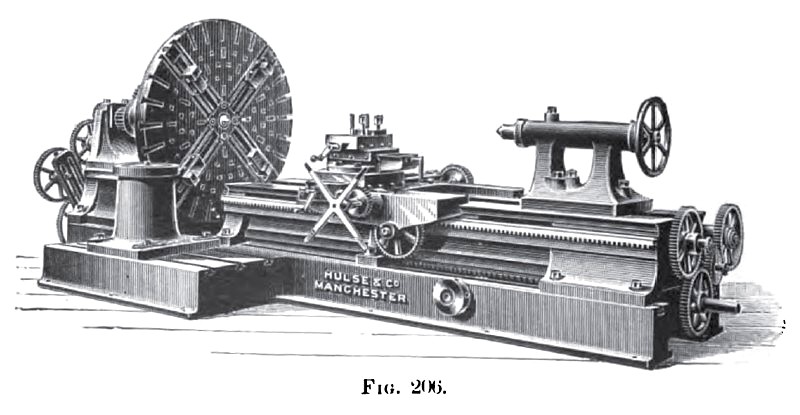

An English break-lathe by Hulse & Co., Ltd., is shown in Fig. 206. In a break-lathe the width of opening is adjustable. It is, in fact, a movable gap-lathe of large dimensions. The movable bed is adjusted up and down the base-plate by rack and pinion or by screw. In the heavy lathes the rack and pinion are operated by a capstan-boss. The carriage for the slide-rest is movable upon the sliding bed by rack and pinion, generally with a cross-handle, for rough adjustment; also by means of a back-shaft for self-acting sliding and surfacing, and by means of guide-screw and disengaging-nut for screw-cutting.

The upper portion of the rest is made interchangeable with the top of a pillar-rest which is bolted to the base-plate, for turning work in the break. This rest is used for surfacing or turning work of large diameter. The longitudinal traverse of the tool in the pillar-rest is made automatic, when required, by means of a ratchet-feed and rocking-shaft. The fast headstock has usually single, double, and treble-gear, and four or five-speeded cones.

In a break-lathe the centres are given from the mandrel to the top of the movable bed, and not to the bottom of the gap. Thus an 18-inch break-lathe would measure 18 inches from the mandrel centre to the top of the bed, but the gap or break would take in a radius of 3 feet or thereabouts. These lathes are made in centres varying from about 16 in. to 36 in. Other dimensions are given, such as length of base-plate, distance between centres when the break is closed, and the diameter and width, which the break will admit (see Table VII. in Appendix). The poppets on heavy break-lathes are racked along. A bracket is bolted on the front of the poppet, and carries a pinion gearing into the rack used for sliding, and turned by winch-handle; or the rack and gear are internal. |

|

1900 Hulse & Co., Ltd., Heavy Break-Lathe

1900 Hulse & Co., Ltd., Heavy Break-Lathe

|

|