|

Title: |

1900 Article-Faneuil Watch Tool Co., Rivett Bench Lathe with Gear-Cutting Attachment |

|

Source: |

English & American Lathes, 1900 pgs. 108 & 109 |

|

Insert Date: |

12/16/2012 8:18:21 PM |

The Rivett lathes, designed by Mr. E. Rivett, manager of the Faneuil Watch Tool Company, of Boston, U.S.A., are made in three sizes, and are capable of performing a wide range of operations, including turret work. The principal feature of this type of lathe, by which it differs from others used for kindred purposes, consists in the slide-rest. This has two graduated bases. The tool-holder has an eccentric arrangement by which the tools can be adjusted readily. The rest can be taken off bodily and attached to a block clamped to the bed, which brings the face of the rest into a vertical plane, its own proper movements being retained in the new position. The block to which it is attached has a circular movement in a horizontal plane. The universality of movement thus provided, together with index-plates, permit of the cutting of spur and bevel-gears, milling and fluting. Grinding attachments are also provided, and screw-cutting from 10 to 160 threads per inch can be done with special fittings. The head is indexed around the flange of the cone, and there is a draw-bar for split chucks.

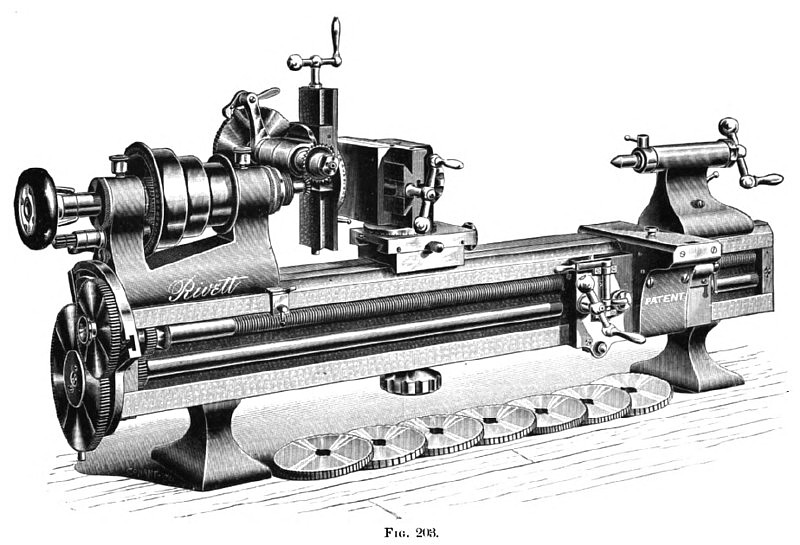

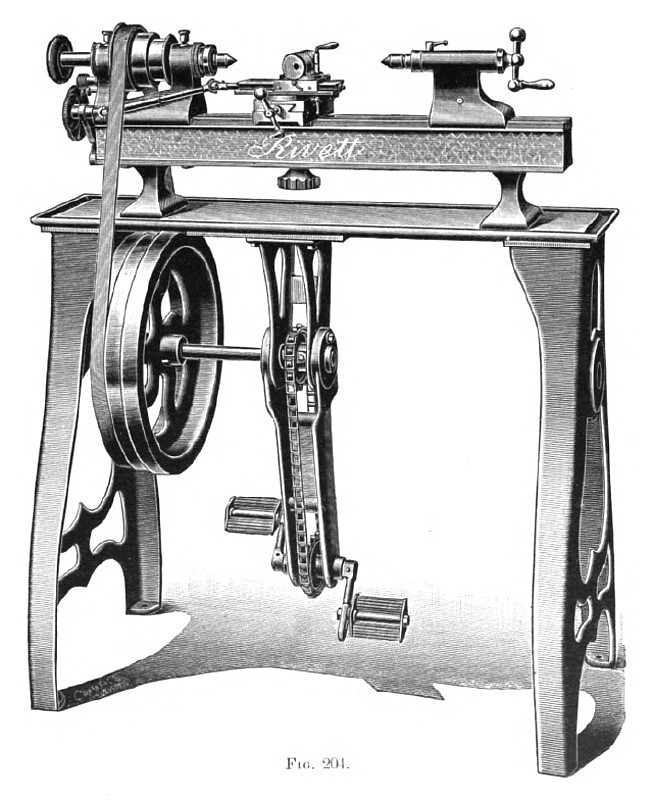

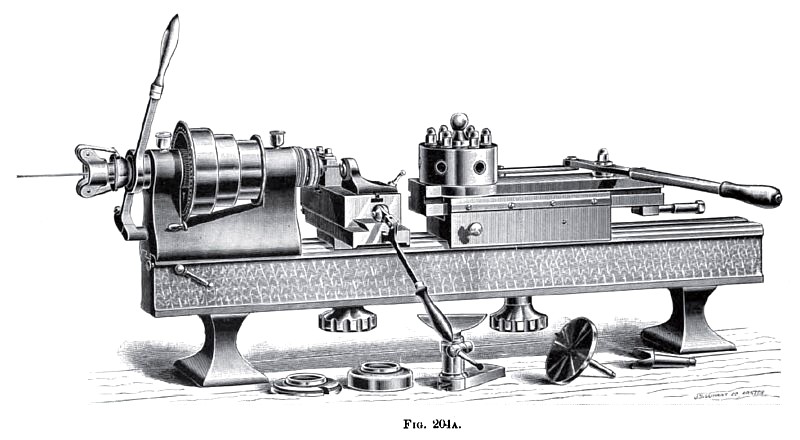

It is not possible to fully illustrate this marvelous lathe here. Three views only are given: one 1 Fig. 203) showing the bench-lathe set up for gear-cutting; another (Fig. 204) the lathe mounted on standards fitted with a bicycle foot motion; the third (Fig. 204a), the No. 4 lathe with turret attachment. The first has lead-screw and feed-rod; the second, a telescopic rod. Fig. 203 represents the most complete lathe, the 8" "Precision" (4" centres).

The No. 3 lathe is of 3½-in. centres, and 18 in. distance between centres; the No. 4 is of the same distance between centres, but of 4-in. centres; the precision lathe is of 4-in. centres, taking 22 in. between. This differs mainly from the others in having a feed-rod and lead-screw. In these lathes the spindles and necks are of steel, hardened in mercury, and ground with diamond dust. The good fitting and the rigidity is such that heavy cutting on steel can be done with remarkable ease. Very small cutters will operate with the greatest precision. Another point in these is, that every part of each lathe, including bed, feet, headstocks, are all milled and polished. The headstock spindles are hollow, and receive split chucks. The special fittings are the following:

The cutter, milling, and gear-cutting attachment made to the rest. Eight index-plates are furnished, and others if ordered. By this attachment balls can be turned, taps fluted, cutters milled, gears cut, without extra belting or overhead. The Faneuil Watch Tool Co. make nearly all their cutters on these lathes. The screw-cutting and taper attachment is in some cases through gear-wheels at the end of the headstock, and a telescopic rod and ball joints.

The No. 4 and the precision lathes are fitted with a turret to render them adaptable for screw-making, the intention being to render an ordinary lathe suitable for screw-making when required for that purpose for a limited period only, the change being effected within two minutes. The turret has six 11/16-in. holes, and a stroke of 4 in. The split chucks are suitable for stock from ½ in. downwards. They are hardened and ground with diamond dust. There is a cutting-off and forming slide, in which cutters can be held and operated for angular and curved forms.

The cut-off slide is utilized as a slotter by turning it round parallel with the lathe-bed. So that after a wheel has been bored, a keyway can be slotted with the certainty of the keyway being true with the bore. The stroke and feed are imparted by hand.

The 8-in. precision lathe (4-in. centre) has feed-rod and lead-screw protected in a recess in front of the bed, over which the carriage (front-slide) moves. The driving of either is through the change-wheels used for screw-cutting, and the feed-rod is operated by a friction-gear at the end, which will slip in case of obstruction.

A traverse miller and grinder is fitted to the 8-in. lathes, being used for fluting, channeling, keyway cutting, and grooving generally. It is attached to the slide-rest, is driven from an overhead, and thence through spiral gears to the cutter.

There is a grinding attachment driven from overhead, besides that fitted to the milling-head just mentioned. There is also a vertical turret to go on the tailstock, besides very numerous chuck-centres, rests, steadies, etc. |

|

1900 Faneuil Watch Tool Co., Rivett Bench Lathe with Gear-Cutting Attachment

1900 Faneuil Watch Tool Co., Rivett Bench Lathe with Gear-Cutting Attachment

1900 Faneuil Watch Tool Co., Rivett Lathe with Bicycle Foot Drive

1900 Faneuil Watch Tool Co., Rivett Lathe with Bicycle Foot Drive

1900 Faneuil Watch Tool Co., Rivett Bench Lathe with Turret Attachment

1900 Faneuil Watch Tool Co., Rivett Bench Lathe with Turret Attachment

|

|