|

Title: |

1900 Article-Lodge & Shipley Machine Tool Co., 7 inch Centre Engine Lathe |

|

Source: |

English & American Lathes, 1900 pg 21 |

|

Insert Date: |

12/14/2012 9:57:04 PM |

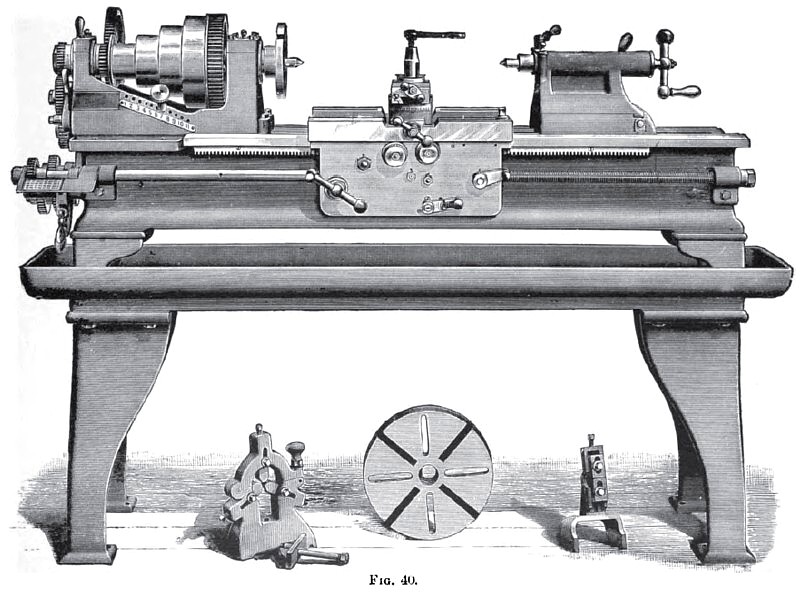

The Lodge & Shipley lathes comprise several features of interest and value. That of 7-in. centres is shown in Fig. 40. The principal feature lies in the change-gears, which are mounted on a short shaft running in bearings in the bed, and directly under the headstock.

The knob shown in front of the head carries a gear that continually runs either right or left. This gear may be dropped into any one of the steel change-gears instantly, and thus gives any one of forty changes of speed, because on the outer end of the change-gear shaft are four gears, into any one of which the gear shown on the lead-screw may engage. Not a single gear is ever removed to obtain the different threads, or feeds. A plate is used to change from right to left-hand screws. The index-plate has the words "Threads," "Knob," on the upper line. Under the word "Threads" are the number of threads the lathe will cut; under the word "Knob" are the figures one to ten; thus, should the operator desire to cut any certain thread, he finds this on the index-plate, engages his gear opposite to it, places the knob in the hole indicated on the plate, and starts his tool to work. The spindle is of steel, running in bronze bearings, end thrust being taken by steel collars. It is hollow. The lead-screw is used for feeding, through a spline. Reversal is effected at the apron. The carriage bears its whole length on the vees.

Both the upper and lower slides are fitted with taper gibs, which, besides being tapering, are tongued and grooved into the sides, to resist strain. The taper gibs are provided with only two screws, one at front and back, which take up the wear the entire length, and which will not require re-setting, perhaps, more than once a year. The top slide is wide, so that heavy cutting may be done without projecting the tool out away from the rest. It has a long movement for angles, and is fitted with a screw of ten pitch. The screw is provided with an indexed micrometer divided into lines, each of which reads 2-1000th. This is for the purpose of reducing material as required, and reading the diameter without the use of calipers, excepting as tests. The lower slide is provided with a micrometer divided into 64ths of an inch, thus every line the screw is turned in a given direction will indicate a change in diameter of the stock of l-64th of an inch. A turn of sixty-four lines will reduce the stock one inch. When starting the cut, an exact diameter may be obtained without the use of calipers, by using the tailstock spindle as a gauge. For. example, having say in the 18-in. lathe secured the tool firmly in place, move it forward until the point touches the spindle; the tool is then set to turn a diameter of two inches. If smaller diameters are wanted, move forward by the micrometer the required amount as explained. If larger diameters are wanted, move backward in the same manner, except that in moving backward a half turn more than is required should be made and then brought back to the proper place in order that lost motion may not cause confusion.

The Lodge & Shipley Co. guarantee in writing that their lathes will bore, face, and turn true within l-1000th of an inch in any length. Taper turning attachments are fitted to these lathes. The change from straight to taper is made by tightening or releasing one screw. When attached for taper work, the sliding-shoe connects directly with the tool rest and not with the screw, making its operation instantaneous. The nut is made to release and slide in a groove. The stud for the sliding-shoe also engages into a groove, and to attach and detach requires nothing more or less than the releasing of one screw and tightening another, or vice-versa |

|

1900 Lodge & Shipley Machine Tool Co., 7 inch Centre Engine Lathe

1900 Lodge & Shipley Machine Tool Co., 7 inch Centre Engine Lathe

|

|