|

Title: |

1900 Article-Springfield Machine Tool Co., 9-in. Centre Engine Lathe |

|

Source: |

English & American Lathes, 1900 pg 19 |

|

Insert Date: |

12/14/2012 8:59:43 PM |

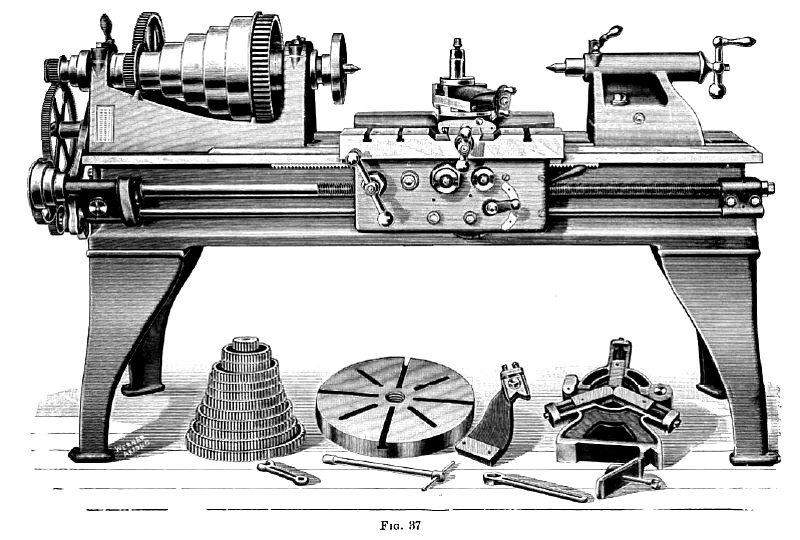

Fig. 37 illustrates one of the Springfield "Muller" lathes, made in from 7-in. to 15-in. centres. The spindle in the 9-in. centre lathe,—being the one illustrated, and which is journalled in hard bronze boxes—is bored to receive l¼-in. round bar in the rough, and is made from a forging of hard crucible steel, in one piece with the collar, which forms a suitable surface for the face-plates to screw against. The value of this arrangement becomes apparent in connection with large hollow spindles, as it not only affords an ample shoulder for the face-plate, but also permits of making the nose of the same large enough to carry the heaviest chuck work without the necessity of making the diameter of the front journal of the spindle excessively large, which in this case is 2¾ inches. The diameter of nose is 2½ inches, by 2 inches long, threaded two-thirds of its length, with four threads per inch. U.S. standard. This form secures some important advantages, namely:—

The face-plates have a straight bearing on the nose equal to one-third of its length, which insures better wearing qualities, and facilitates placing them in position, and, as the pitch of the thread is coarse, a tendency to wedge so tightly as to become difficult to remove is avoided.

The carriage is 24 inches in length, with full bearings on vees, and is gibbed to the outside of the bed. Either a plain or compound rest is furnished at the option of purchaser. These are fitted with long and wide bearings on carriage, with adjustable taper gibs to compensate for wear. The compound-rest is so arranged that its handle may be revolved without interfering with the cross-feed handle in any position. The base, which is graduated in degrees, securely holds the top by means of one bolt, when

swiveled to any angle. The feeds are driven directly from the spindle, either with change-gears or belt, and are reversed in the apron, where provision is made so that friction-feed and lead-screw cannot be engaged at the same time. Belt-feeds are proportioned to give 80, 50, or 30 cuts to the inch. With the gearing a range of feeds from 5 to 105 per inch is possible.

The handle shown in front of the lead-screw box at the headstock end of the lathe must be turned to the right or left to respectively engage the gear or belt-feed, or vice-versed, without the necessity of disengaging the change-gearing or removing the belts. A very desirable combination is secured by this device, its construction making it possible to give the belt any required tension necessary to perform its duty without slipping, and as the belt may be made endless, the annoyance from breakage and re-lacing is entirely avoided. The motion is transmitted from the spindle to the lead-screw by the least possible number of gears, all of large diameters, ensuring steady and regular work, which is of great value in cutting accurate screws. |

|

1900 Springfield Machine Tool Co., 9-in. Centre Engine Lathe

1900 Springfield Machine Tool Co., 9-in. Centre Engine Lathe

|

|