|

Title: |

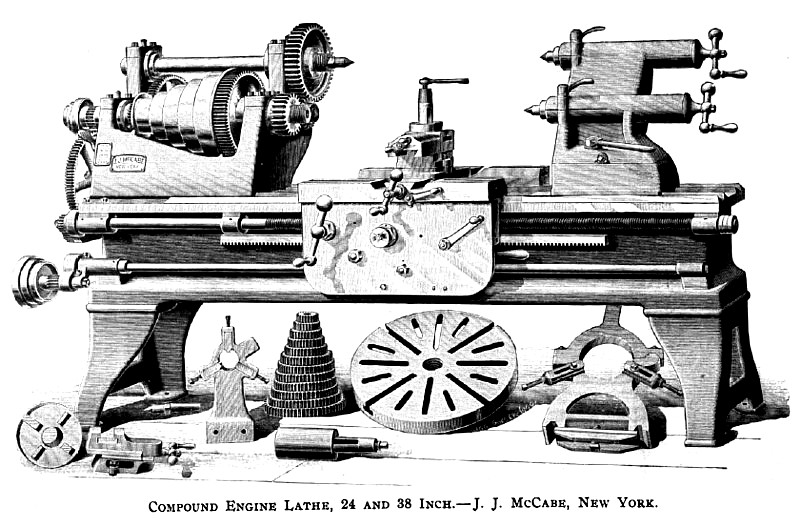

1895 Article-J. J. McCabe Lathe & Machinery Corp., 24 & 38 inch Compound Engine Lathe |

|

Source: |

Industry Magazine, Dec 1895, pg. 706 |

|

Insert Date: |

2/27/2017 7:02:32 PM |

Last month we had mention of the invention and introduction of what may be called compound engine lathes, shown in the fine drawing on the following page. These lathes, as will be seen, have two sets of spindles, one for special work of much larger diameter than the rated or normal capacity, affording in much better form the advantages of that awkward type called “gap lathes", which have happily never made much way in this country. To meet the objection, and the only one we can think of, to the compound arrangement shown, that lathes should not be employed for work beyond their rated capacity, there is this answer. Lathes are so employed continually, and properly too in very many cases, and this is attained by blocking up the heads, not only by the users, but frequently by the makers. This is a very imperfect expedient when compared with an auxiliary triple-geared spindle set in such a position as will keep the turning strains within the proper plane over the main frame, and calling for no change of the feed or train-wheel connections. In a fully-equipped works there are tools adapted for all kinds of duty, and no requirement for other than the standard types of implements, but for one such case there are several that lack such facilities. In repair shops for factories and mines, on steamers and in country places, it is impossible to keep a lathe at work within its rated capacity unless it be much too large for the average work, and the compound spindle expedient seems to best meet these circumstances, that is, accomplishes the work with the least expense and in the best manner. As a matter of fact there is no direct adaptation of "engine lathes". Take, for example, a lathe of 24 inches swing, the most of its working time is spent on pieces of less than six inches diameter, and the full swing is at best an emergency use. The natural division would be different lathes for long and short work, that is, for shafts, rods, screws, studs, etc., and a different class for pulleys, wheels and the like, of large diameter also a compound lathe like the present one has equal claims in the way of adaptation. The upper spindle, as will be seen, is triple geared, the last -mover driving on the face plate, so its rigidity is quite equal to the lower one, and "its position is better for all kinds of exterior turning, in fact it is in the position that the lower one should have for all kinds of turning, that is, set over the rear side of the frame. The only alterations required in changing from one spindle to the other is to place and remove the intermediate pinion between the spindles and change the face plate" and tool supports. These latter we think should have a wider base on the carriage than is indicated in the drawing, and have proportions intermediate to the two spindles, which may, however, be the case in practice. We are becoming tired of the stereotyped engine lathes and must congratulate the makers of this one for having at least “got out of the rut". We do not complain of quality, or even of performance, with standard lathes, but when an implement applied to so many diverse purposes is made without discernible difference in design it certainly indicates a want of the best adaptation.

US Patent: 368,021

http://datamp.org/patents/displayPatent.php?number=368021&typeCode=0 |

|

1895 J. J. McCabe Lathe & Machinery Corp., 24 & 38 inch Compound Engine Lathe

1895 J. J. McCabe Lathe & Machinery Corp., 24 & 38 inch Compound Engine Lathe

|

|