|

Title: |

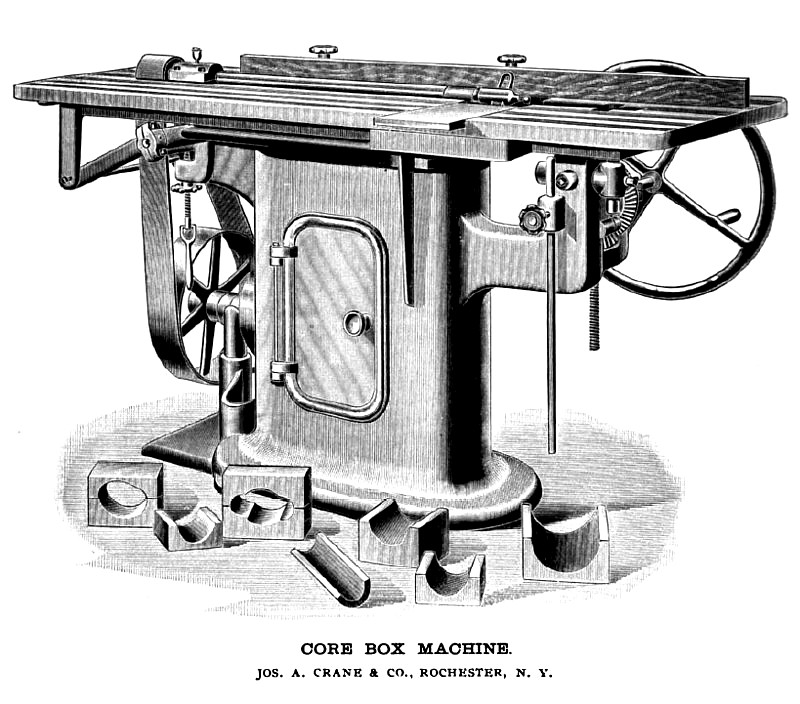

1895 Article-Joseph A. Crane & Co., Core Box Machine |

|

Source: |

Industry Magazine, Mar 1895, pg. 152 |

|

Insert Date: |

12/11/2012 3:14:00 PM |

The peculiarities of these machines are that the work, whatever it may be, is cut at once to exact or finished dimensions by the saws irrespective of the grain, and smooth enough to be sand-papered and varnished without planing.

It is not very easy to keep the flask maker and packing box people away from these machines, and a great share of pattern makers cannot understand and take care of such saws, so we sometimes find a fine dimension machine employed for cropping up boards and the like, the same as a common saw bench.

Pattern work is not uniform; no two things are alike, because only one can be required. This has limited the application of machine tools to this work, but there is one part that has some uniformity and should be made by machines whenever possible, that is, cylindrical core boxes. Working out core boxes, which is supposed to not require much accuracy, is commonly not very well done unless they are made on lathes. The work is tedious and hard too, if the cores are large, and as said at the beginning, the wonder is that core-box machines have not sooner appeared.

Messrs. Crane & Co., the makers, send us the following statements respecting the machine shown in the illustration. It is exceedingly well designed, provided with convenient and rapid adjustments, and a credit every way to the makers.

"This machine is adapted to the making of patterns, core boxes, pulley bushings, etc. It will groove a semi-circle core box absolutely true in a few minutes, where hours and sometimes days are required to do the same work by hand; cut grooves from ]4 in. to 20 in. in diameter, any length; form any internal circle work on exterior of patterns, such as inside of staves, making coves, or cut inside of round boss so as to fit perfectly the exterior of a round pattern; will cut with, across, or on the end of the grain, and leave the edge smooth and clean. In pattern work it does away with a good deal of work that is now done by hand, and can be used for many different purposes.

The machine is of substantial design; frame is made in one solid casting, spindles are made of steel, and consist of main spindle, to cut from 1¼ to 20 in. diameter. An extension spindle is fitted to the main spindle, to enable the operator to cut small grooves from ½ to 1¼ in. diameter. Self-oiling brass strap box at the cutter-head. Spindles are driven with an endless belt, and the countershaft is adjustable so as to keep the belt at proper tension. The cutter-heads are of brass, provided with single or double adjustable loop cutters. Weight of machine, 700 pounds. Floor space required, 36 X 20 inches. In any case where there is work enough to keep one of these machines running constantly, it will pay for its cost in one week." |

|

1895 Joseph A. Crane & Co., Core Box Machine

1895 Joseph A. Crane & Co., Core Box Machine

|

|