|

Title: |

1895 Article-Gisholt Machine Co., Heavy Turret or Capstan Lathe |

|

Source: |

Industry Magazine, Mar 1895, pg. 148 |

|

Insert Date: |

12/11/2012 1:15:46 PM |

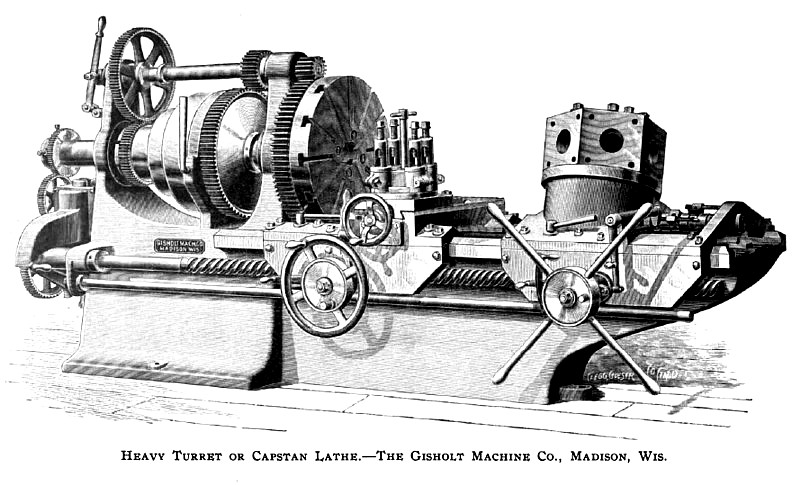

The Gisholt Machine Company, of Madison, Wisconsin, has conferred a public benefit in this country by making and introducing the turret or gauge tool system for a great variety of lathe work.

This country has been notably in the lead for thirty years past in turret machines for making screws, and a variety of other things, such as parts for watches, guns, and so on, by milling tools, but for some strange reason has not until recently extended the system to the wider field of common machine work for such parts as are made in duplicate, or even in general work.

In this we are behind works in England, where for at least fifteen years past a great deal of work has been done by these gauging or turret lathes, using common tools the same as for ordinary engine lathes.

The processes we are trying to describe consist in accurately setting a number of tools on a turret, or by "presenting" devices so that the tools can be used repeatedly without fresh setting and adjustment each time they are wanted.

It is a method not entering into the use of a common engine lathe, where each tool as it is wanted must be set in the machine and adjusted each time it is used. In this turret-tool system the slide rest or supporting elements are not in the axis of the lathe, as in the case of milling tools, but set to one side, so the manner of cutting is analogous to that of engine lathes, and, as seen in the drawing, the turret can be employed in conjunction with a traversing slide rest for cutting off, facing, or other operations normal to the axis of the work.

In English shops where the turret system is carried out, the work is divided into two classes, one for common engine lathes, and one for turret lathes. The draughtsmen know what kinds of work are suited for the turret shop, and such pieces are drawn on separate sheets, and so marked, and by thus segregating the work, and by constant practice the turret men or boys become so expert in adjusting the machine that in cases where six or more pieces are to be made alike they are included in the turret class.

Some years ago we sent to a well-known English firm and procured some examples of turret-lathe work just as they came from the machine, with a list of prices for each piece, but it seemed incredible, and produced no result, the fact being that at that time there was so little work done here that required duplication, people could not see the advantages of the system.

The Gisholt Company send illustrations of work done, as seen in the drawings, with, in some cases, the dimensions and time of making marked below. There is sent besides the following data in respect to making some familiar parts of machine work.

For example, a step pulley with three faces, 6 3/8-inches wide, the pulleys 12, 18 and 24 inches diameter, with an extension of the small pulley, making the total length 23 inches. This pulley, having over 1,200 inches of surface, was turned all over, except the inside of the two small pulleys, in 3½ hours, or, as we estimate, one fourth of the time required to do the same work on an engine lathe.

Another example is a bonnet for the valve stems of Corliss engines. The base or flange is 10 inches square, large diameter 8 inches, length over all 19 inches, for a 2-inch stem, bored and finished in 1¼ hours.

The drawing shows one modification of these lathes, which are quite different and much heavier than those used in England, but a drawing of the machine in one position, or in one adjustment does not cover more than a single idea of the scheme. They are modified in various ways, and adapted for making valves, gear wheels, studs, and so, but are convertible to almost any work in machine fitting. A number of these lathes have been supplied to firms in Europe, and their manufacture is a credit not only to the makers but to the industry in general. |

|

1895 Gisholt Machine Co., Heavy Turret or Capstan Lathe

1895 Gisholt Machine Co., Heavy Turret or Capstan Lathe

|

|