|

Title: |

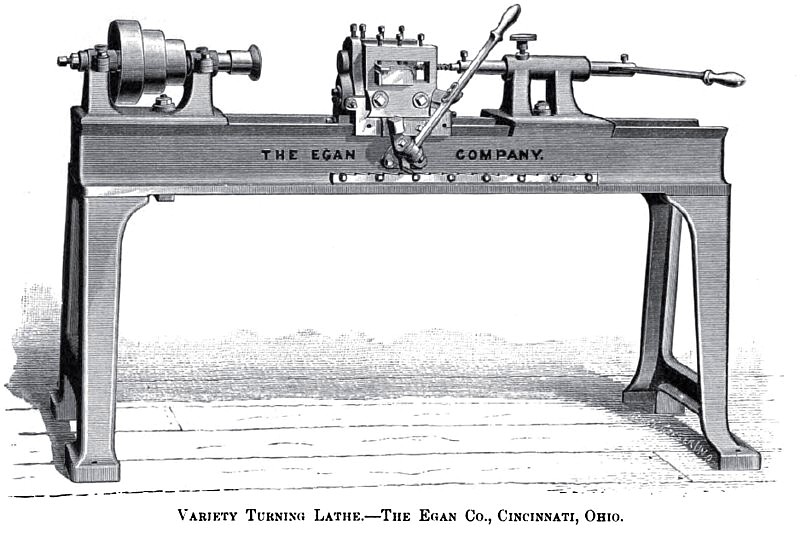

1890 Article-Egan Co., Variety Turning Lathe |

|

Source: |

Industry Magazine, Aug 1890, pg. 14 |

|

Insert Date: |

12/8/2012 9:07:46 PM |

The lathe shown herewith is a type that came into use a good many years ago, for turning small articles of wood that require to be exactly duplicated, such as druggists boxes, spools, bobbins, buttons, and so on; the forms being produced by profile cutters with thin sharp edges that leave the work smooth. The sliding stock is employed for boring or what may be called "interior work," and the whole machine is fitted up with the same care and exactness as an engine lathe. The Egan Company, who send us the engraving, have added several improvements to this class of lathes, and are making them to perform a very wide variety of work.

We are reminded in looking at this machine, of turning tent buttons in 1861, during the war in this country. These buttons were employed in fastening the canvas of tents, and corresponded to what is called wooden moulds for buttons, but were much larger, with a hole in the center to receive a cord one fourth inch diameter. A million or more of these were ordered by the Department, from the Ohio Tool Company, at Columbus, Ohio, also at the same time 30,000 drum sticks of cocoa wood. To the consternation of the contractors it was discovered that common gouges and chisels would not cut the wood, because of its hardness and grit, so the process of turning was carried on mainly by scraping with blunt tools. The contract was filled at a loss to the Company.

There were then no lathes of the present kinds and the tent buttons were attacked by the turners, on common lathes. Small holes were bored through the "blanks" and the buttons were cut from the end, following up with the tail stock, as they were cut off. The holes were then

enlarged in a separate lathe and the buttons strung 100 in a bunch ready for delivery. We imagine that one man with a lathe like the one illustrated, would have turned as many such buttons as ten men could by hand, with the important difference too, that all would have been alike. There is no branch of manufactures where machine processes have so sudden and extensive effect as in wood working. The enormous speed of the edges at 5,000 or even 10,000 feet a minute, destroys all analogy to hand work. In old times 100 feet of matched boards was a day's work for one man; now a machine will prepare 10,000 feet or 100 times as much as a workman can do by hand, and the cost of the machine work including power is not more than three times what was paid to the man, so the saving is over 600 per cent. In the operation of the lathes shown, counting numbers alone and omitting quality, which is all in favor of the machine, the gain is at least ten times over hand work.

The cutting is natural, comparing to that done by hand chisels and gouges, but the edges last a good deal longer, that is, will do more work without sharpening. The natural form of cutting in all turning apparatus is to have the ' face' of the tool nearly tangential to the piece, the edges thin and set slightly diagonal to the axis of rotation, or the center of the piece. As a machine and its tools approach these conditions, so is the work good or bad. Nearly all operations in wood working can be predicated on rules of the kind.

Shape turning machinery has been mainly of American origin during fifty years past, and is very creditable to our engineering skill; so also machinery for what may be called the "finishing" processes in wood-working. In sawing and planing wood we have not much to boast of. Cheap timber, and the methods of dealing in sawn timber, have acted to prevent reforms. |

|

1890 Egan Co., Variety Turning Lathe

1890 Egan Co., Variety Turning Lathe

|

|