|

Title: |

1894 Article-Weston Engine Co., High-Speed Automatic Steam Engine |

|

Source: |

Industry Magazine, Sep 1894, pg. 528 |

|

Insert Date: |

12/8/2012 1:32:22 PM |

The automatic type of steam engines regulated by variable range or cut-off in the steam-distributing valves has met with universal favor in this country for several reasons. Among these, it was an extension in a more simple form of expansive regulation introduced in the famous Corliss type of engines, also because the exigencies of high speed opened a congenial field for American engineers.

High speed has been a constant characteristic of machinery of most kinds in this country, now introduced, it is true, in various European countries, not only, or indeed so much, in steam engines as in other kinds of machinery, especially what may be called converting implements for iron and wood. In working wood, for example, and speaking of twenty-five years ago, mortising machines were driven in Europe at from 60 to 80 revolutions per minute, and in this country 250 to 400 strokes. Moulding machines had there a lineal feed of 15 to 25 feet per minute, and here 40 to 60 feet. Rotary spindles of all kinds for woodworking were driven at very nearly double the speed common in Europe. The same remark applies to metal-cutting processes. The American idea seemed to be a high rate of movement and slow feed, rendered necessary, perhaps, by a lighter construction of machine tools at that time, lighter sections for the parts or pieces operated upon.

There were exceptions, it is true. The speed of railway trains for one thing, also the speed of reciprocating saws, and in some other cases where mass enabled a more rapid rate of reciprocation or revolution, but an average of all American practice tended distinctly to high speed, and there is little wonder that when the weight and, to some extent, the first cost of steam engines was discovered to be inversely as the speed of revolution ; that element became a matter of evolution, reaching limits that had never been thought of before, but it was soon found that both weight and cost had to be in proportion to horse power, or should be so, except as to fly wheels.

High speed demands permanently connected motion rods and valve gear, and, as before remarked, when the variable cut-off function was found possible without detachable gearing the "art" sprung ahead at a wonderful pace, and has not only supplied an almost indispensable element in generating electric currents, but it has done more to improve constructive features than any other change of our time, or of any time. No sham work was admissible, no material but the best could be employed, and no cutting down of proportions without commercial risk that could not be assumed.

Under these conditions and requirements the makers of high-speed engines have, in most cases, engraved to scale the main parts of their engines, showing definitely the proportions and manner of construction. It is wonderful, and affords the best example of what is technically called "working out" that can be referred to in modern machine practice.

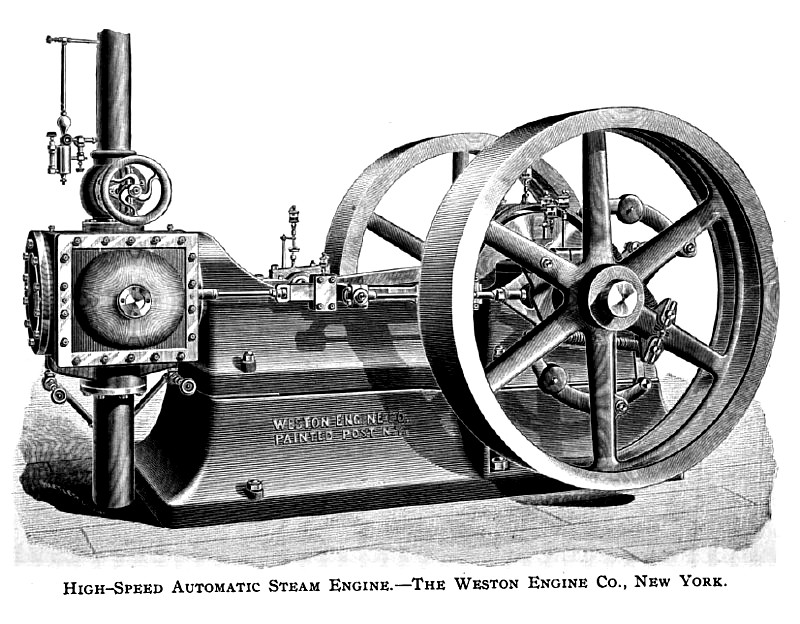

These thoughts come to mind while turning over a catalogue of the Weston Engine Company, recently received, and by noting, as a mechanic, the provisions for compensating strain and wear. We have not space to reproduce examples of the parts, but publish at the head of this article a drawing of a Weston engine of the most simple form as it appears when erected. In examining the sectional views, one familiar with old-time practice gets the impression that all the parts and elements of the engine have been doubled, except the bore of the cylinder, which remains the same. Indeed this estimate is not far wrong.

Turning to tables of dimensions we find the speed of revolution recommended to be from 500 to 600 feet per minute, or about twice the old standard, and the weight of the engines arranged as shown in the drawing reach 1,700 pounds for each inch of bore for engines of 150 horse power, and 1,000 pounds for engines of 60 horse power, which is at least double what was thought necessary only a few years ago. There are many new features and suggestions in the practice shown by the catalogue named, and the engines are worthy of careful study, as an advanced type in the class to which they belong. |

|

1894 Weston Engine Co., High-Speed Automatic Steam Engine

1894 Weston Engine Co., High-Speed Automatic Steam Engine

|

|