|

Title: |

1894 Article-E. W. Bliss Co., Automatic Shearing Machine for Muck Bars |

|

Source: |

Industry Magazine, Jun 1894, pg. 348 |

|

Insert Date: |

12/8/2012 9:48:51 AM |

In the process of rolling steel into thin sheets it would be impracticable to roll each sheet separately, as it would not retain its heat, and the following method is adopted:

A billet of steel of sufficient size to make a large number of sheets is heated and passed a number of times through a train of rolls, each pass lengthening the bar and reducing its size. It leaves these rolls in the form of a bar twenty or thirty feet long, and something like an inch thick by eight inches wide, these dimensions depending upon the size and gauge of the sheets to be made.

These bars, technically known as muck bars, are cut up into uniform lengths, and each piece is then repeatedly re-rolled and folded over, and passed through double, quadruple and so on, the metal not being hot enough to weld or adhere together, each operation reducing the thickness and increasing the linear dimensions, and each folding doubling the number of sheets in the final pack. After the last rolling the ends of the pack are sheared, leaving each sheet free to be separated.

It is very important that the pieces into which the muck bar is divided should be of uniform size and squarely cut, as upon this depends the size and form of the subsequent pack, and it will easily be seen that any error will be largely exaggerated with the successive passes through the rolls.

The method heretofore employed for shearing the muck bar has been to carry the bar to the old-fashioned alligator shear, place the end against a fixed gauge, which determined the length of the pieces, and pass the bar along by hand for the successive cuts. This method not only requires the labor of several men to handle the bar, but calls for considerable skill on the part of the shear man, and unless great care is used the results are liable to be unsatisfactory.

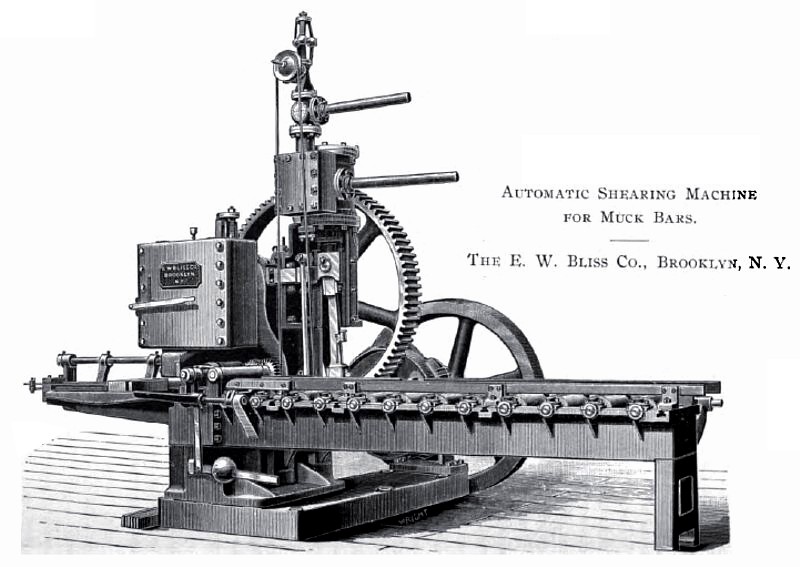

The illustration represents a machine by the E. W. Bliss Co. for doing this work automatically, thus requiring but one unskilled man to do the work.

The machine consists of a powerful gate shear driven directly by an engine. A clutch is attached to the engine shaft, which can be operated either by hand or automatically. To the right of the machine is a carrier composed of a train of rolls driven continuously. The muck bar, coming hot from the rolls, is placed upon these carriers, which propel it toward the cutters between side gauges, which keep it in position at right angles to the shear blades. Just before entering between the cutters a pair of feed rolls take hold of the bar so as to feed it positively.

The forward feed of the bar is controllable by hand, so ragged or first ends can be cut off, after which it moves forward against the gauging devices seen on the left. This engages a clutch that sends the shear knife down, cutting off uniform lengths continually until the whole bar is reduced to " lengths."

The machine is driven by a steam engine, forming an integral part of the structure so it can be set anywhere in a rolling mill. There are a number of these machines in use that have led to a considerable saving, being rapid in operation and dispensing with skilled attendants. |

|

1894 E. W. Bliss Co., Automatic Shearing Machine for Muck Bars

1894 E. W. Bliss Co., Automatic Shearing Machine for Muck Bars

|

|