|

Title: |

1894 Article-Fulton Engineering & Shipbuilding Works, Corliss Steam Engine |

|

Source: |

Industry Magazine, Feb 1894, pg. 100 |

|

Insert Date: |

12/6/2012 9:39:56 PM |

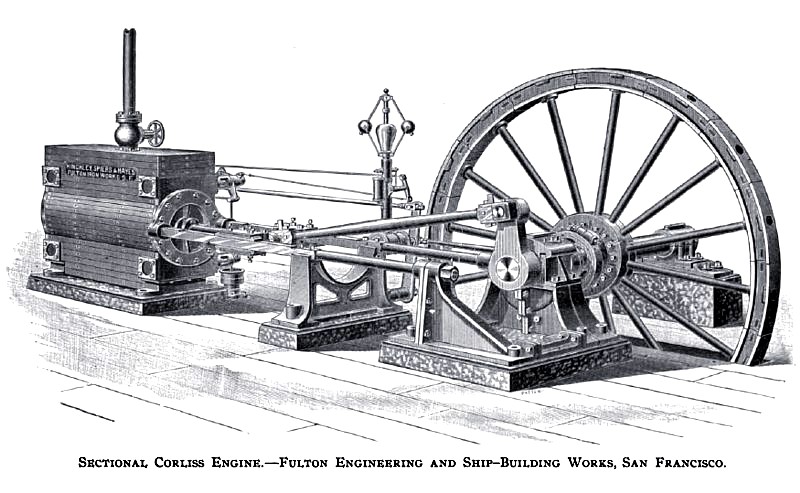

The drawing on the opposite page shows a very ingenious arrangement of a sectional Corliss engine made to a limit of 300 pounds for the heaviest piece, except the crankshaft.

Machinery constructed in sections, so as to be transported by carrying-mules to stations in the mountains where there are only trails, is an important feature of engineering practice on this Coast, and a perplexing one sometimes.

The two main conditions in such work are directly opposed; separation and weight. Segregation increases weight, but is done to avoid weight; so the problem is not confined to dividing the parts, but includes a careful attention to strains, the disposition and strength of material. The chances are that the duty will be severe. When one buys an engine to be transported over mountain passes on '' burros '' the heating surface and cylinder capacity are reduced to their least limit, which means heavy duty. The present case proves this. The engine, 18" X 36", when started ran eight months continuously, day and night, with a detention of eight hours or one hour each month, a record that, so far as we know, has no precedent.

The division of the main pedestal and the fly wheel can be followed out in the drawing, but the cylinder, which is in nine or more pieces, being covered in, nothing can be seen except that the contour is the same as for a standard engine of the kind. The cylinder is divided transversely into five parts, fitted together and then bored. The side pipes or valve boxes are bolted on, and the base flanges or base part of the exhaust chamber are detachable.

The central stand supporting the guide bars, which are also tie rods, is in a single piece less than 300 pounds in weight. The main pedestal is divided, as seen, into four parts, and has a central chamber under the main bearing to admit of a radial stiffening flange on the bottom of the bearing, which, by this reinforcement, is greatly reduced in cross section and weight.

The nave of the fly wheel is in eight parts, consisting of four segments on each side of the spokes, the joints "broke" and through bolts, so the nave is thus made into an integral member, and the spokes clamped by the same means.

The spokes of the wheel are round bars of wrought iron, three inches in diameter, each fastened by a countersunk nut in the fly wheel rim, which is in sixteen sections or segments, as shown, joined by links and keys in the usual manner. |

|

1894 Fulton Engineering & Shipbuilding Works, Corliss Steam Engine

1894 Fulton Engineering & Shipbuilding Works, Corliss Steam Engine

|

|