|

Title: |

1894 Article-J. T. Case Engine Co., Automatic Steam Engine |

|

Source: |

Industry Magazine, Feb 1894, pg. 88 |

|

Insert Date: |

12/6/2012 12:59:23 PM |

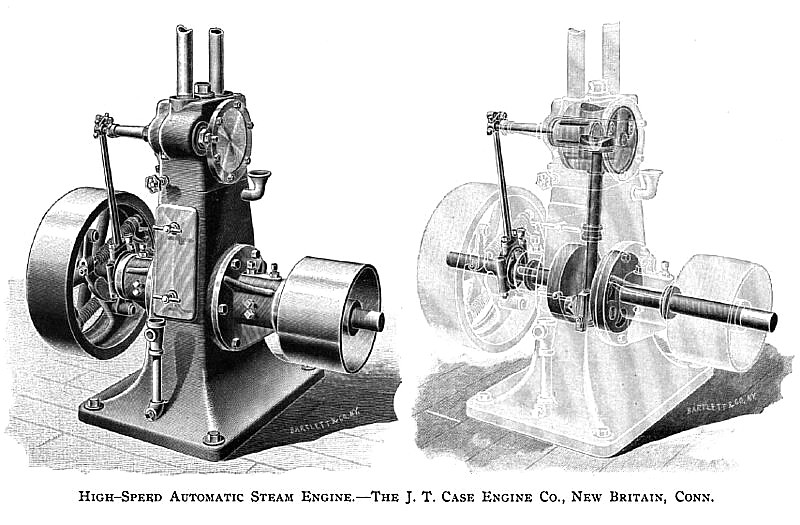

The engravings opposite, showing an elevation and skeleton view of a peculiar steam engine, invented by Mr. J. T. Case, of New Britain, Conn., will be a matter of interest to our readers. We believe that on the score of novelty this engine may take a first place among the many attempts in late years to simplify steam engine construction without abandoning or ignoring any of the essential features of endurance or economy.

At first glance one will be disposed to class the engine with others of the pendulous or oscillating class, subject to strains upon trunnions and steam-packed joints, with large fricrional surfaces and so on, but the operating features when studied, disclose a remarkable freedom from faults thought to be inherent in engines of the class, or appearance rather, because there is really no class to put the present one in.

The cylinder, to so call it, is an oscillating member pierced transversely to receive the piston, and forming, in a sense, trunnions, but there is no strain transverse to the horizontal axis. The upper end being open, as seen in the skeleton view, the strain of the pressure on the downward stroke falls on the cylinder cover, while on the inward or upward stroke a film of steam is admitted to shallow chambers beneath the cylinder or trunnions that counterbalances the thrust on the piston, so the oscillating trunnion cylinder is all the time in equilibrium.

This oscillating member performs the function of fixed steam distribution, and the cylindrical valve, seen in front, acts as a cut-off for regulation, and to govern the rate of expansion. The resistance by inertia to the oscillating movement is reduced to a minimum by reason of the shortness of the cylinder, and is provided for by a long sleeve extending down around the piston rod, half way to the crank, as seen in the drawing.

Analyzed, the engine may be said to be an oscillating one, with an open-ended cylinder, the trunnions as large in diameter as the cylinder's length, relieved from strains, without packed joints, and having a long range of movement so as to attain free and efficient valve movement. The crankshaft, connections, bearings, regulating mechanism, main bearings, and other details are all made with ample proportions, and in accordance with good practice.

These engines are made either throttling or automatic, from 2½ to 25 horsepower, on pedestal frames as in the drawings, with brackets to bolt to walls, or for suspension beneath beams or ceilings. They are also made double, with two cylinders close together, and run at the highest rate of speed that has been attained with reciprocating engines, reaching 550 to 900 revolutions per minute. The business has been founded as a " manufacture," with duplication of parts and standard dimensions. These engines, it seems to us, are especially suited for boats, being made reversible by their valve arrangement, without links or external gearing, but their special adaptation is to what the makers call direct connection to line shafts and machines that are required for use separately. |

|

1894 J. T. Case Engine Co., Automatic Steam Engine

1894 J. T. Case Engine Co., Automatic Steam Engine

|

|